CleaningtheFoamAirCleanerElement

ServiceInterval:Every25hours

1.Washthefoamelementinliquidsoapandwarm

water.Whentheelementisclean,rinseitthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifitis

tornorworn.

ServicingthePaperAirCleaner

Element

ServiceInterval:Every50hours—Cleanthepaperair

cleanerelement.

Every200hours—Replacethepaper

aircleanerelement.

1.Cleanthepaperelementbytappinggentlytoremove

dust.Ifitisverydirty,replacethepaperelement

withanewone(

Figure42).

2.Inspecttheelementfortears,anoilylm,ordamage

totherubberseal.

3.Replacethepaperelementifitisdamaged.

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperaircleanerassemblyinstalled.

1.Carefullyslidethefoamelementontothepaperair

cleanerelement(Figure42).

2.Placetheaircleanerassemblyontotheaircleaner

baseorhoseandsecureit(Figure42).

3.Placetheaircleanercoverintopositionandtighten

thecoverknob(Figure42).

ServicingtheEngineOil

ServiceInterval:Beforeeachuseordaily—Checkthe

engineoillevel.

Aftertherst8hours—Changethe

engineoil.

Every100hours—Changetheengine

oil.(moreoftenindirtyordusty

conditions)

Every200hours—Changetheengine

oillter.

Note:Changetheoilmorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

Note:Therearedifferentoilcapacitiesforthedifferent

modelslistedinthismanual.Ensurethecorrectamount

ofoilisused.

Important:Remembertoadd80%oftheoiland

thengraduallyllittothefullmarkonthedipstick.

OilType:Detergentoil(APIserviceSF,SG,SH,SJ

orSL)

EngineOilCapacity:58ounces(1.7liter)withthe

lterremoved;51ounces(1.5liter)withoutthelter

removed

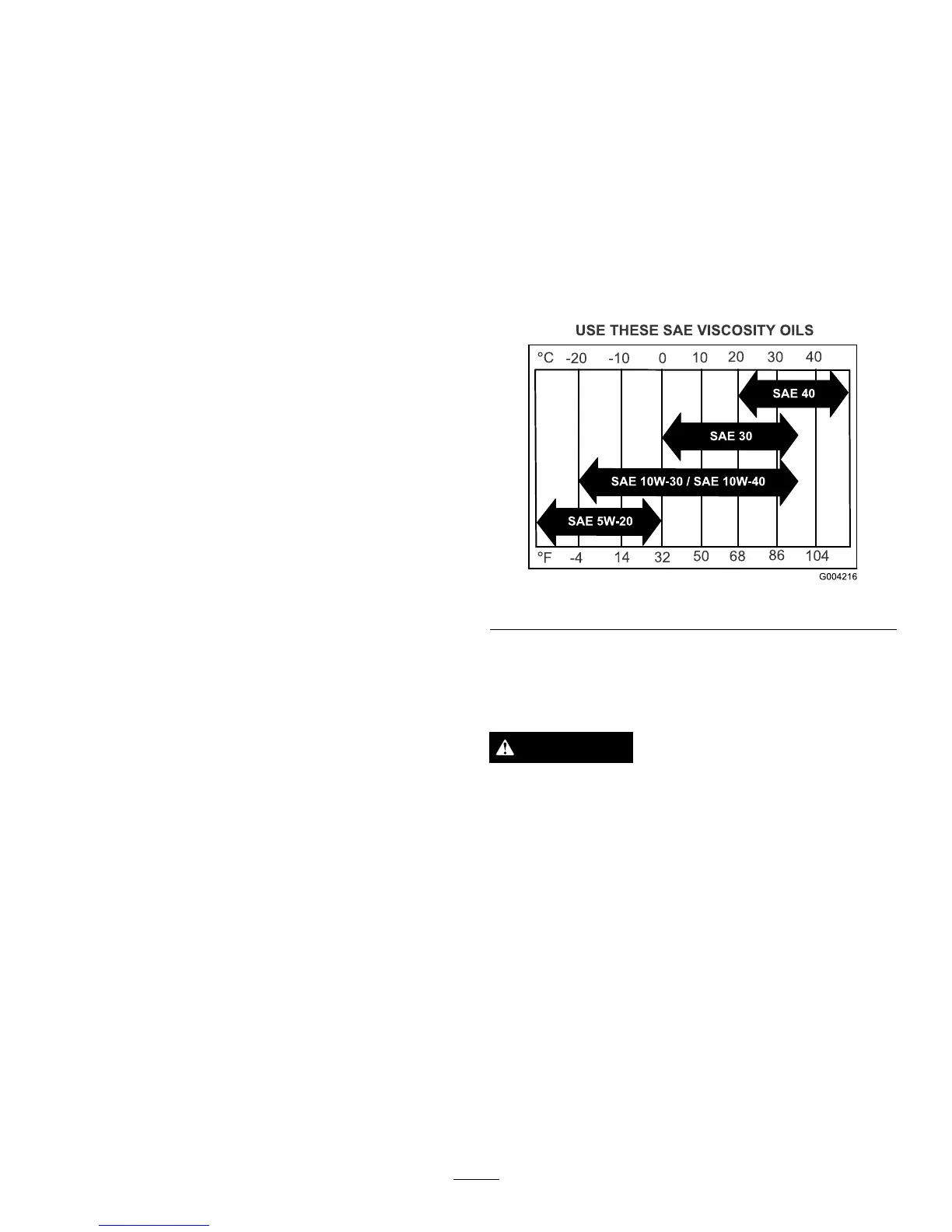

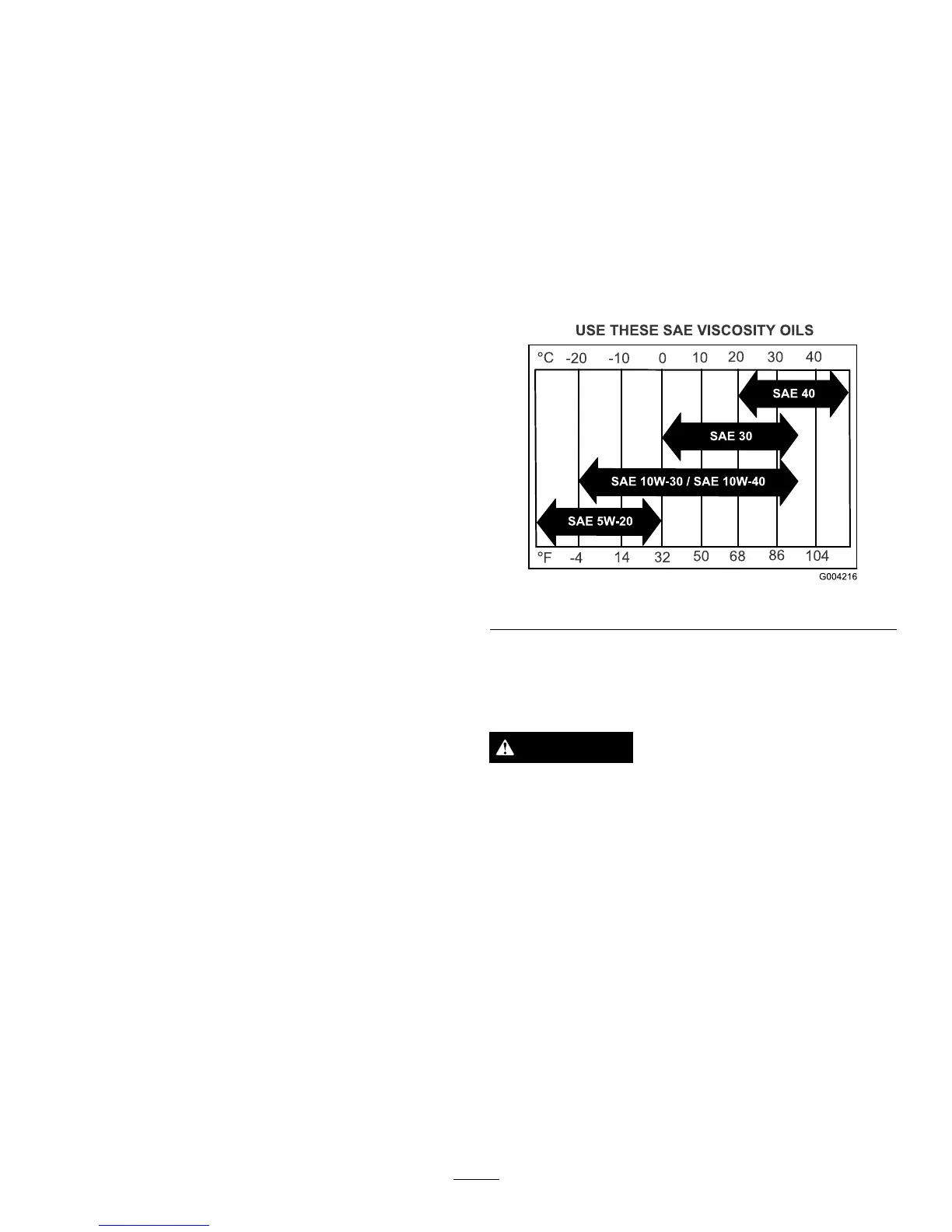

Viscosity:Refertothetablebelow

Figure43

CheckingtheEngineOilLevel

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donot

runenginewithoilbelowthelowmarkbecausethe

enginemaybedamaged.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure44).

35

Loading...

Loading...