themachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturersmay

resultinnon-conformancewithsafetystandards.

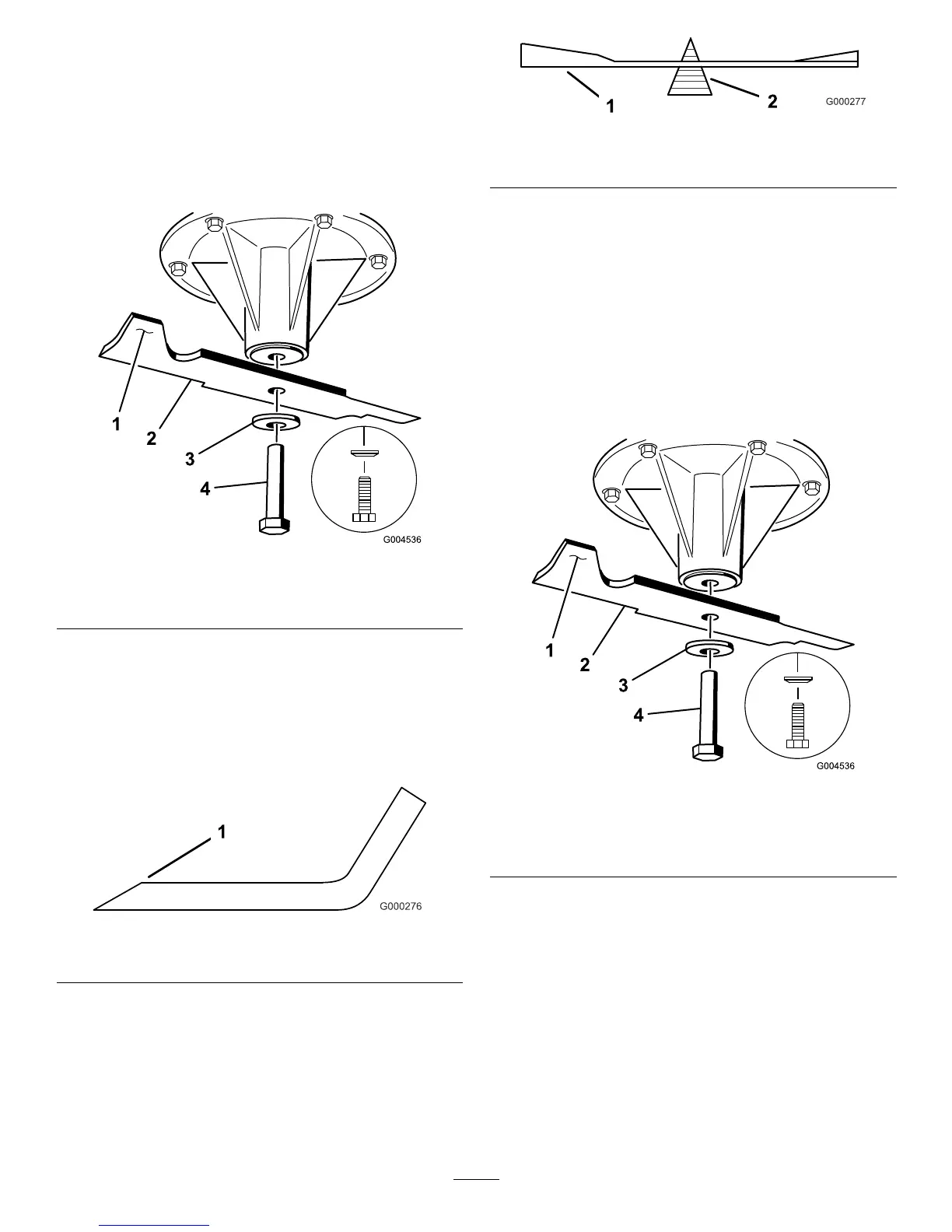

1.Holdthebladeendusingaragorthickly-padded

glove.

2.Removethebladebolt,curvedwasher,andblade

fromthespindleshaft(

Figure80).

Figure80

1.SailAreaofBlade3.Curvedwasher

2.Blade4.BladeBolt

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothends

oftheblade(Figure81).Maintaintheoriginalangle.

Thebladeretainsitsbalanceifthesameamountof

materialisremovedfrombothcuttingedges.

Figure81

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure82).Ifthebladestaysina

horizontalposition,thebladeisbalancedandcanbe

used.Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(Figure80).Repeatthis

procedureuntilthebladeisbalanced.

Figure82

1.Blade2.Balancer

InstallingtheBlades

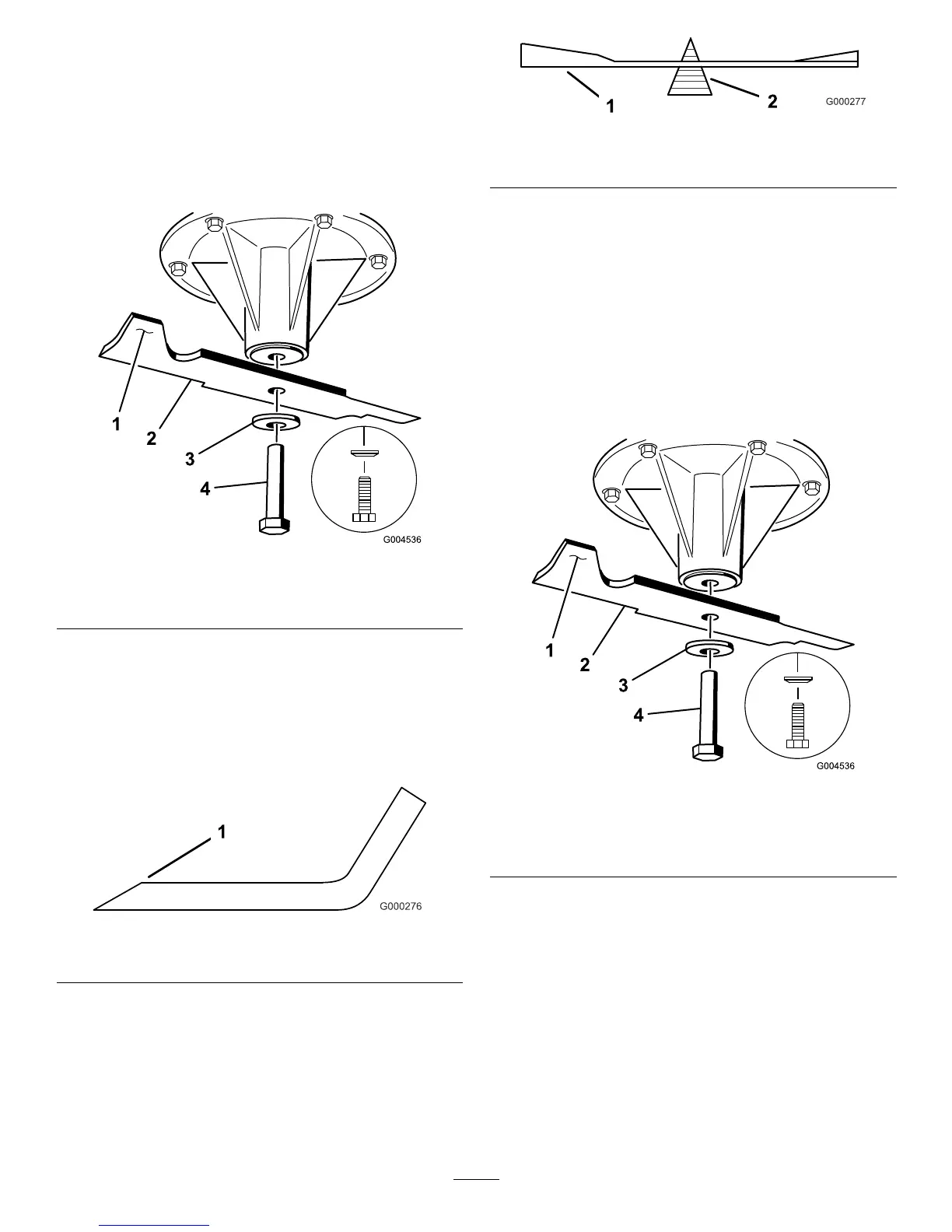

1.Installthebladeontothespindleshaft(Figure83).

Important:Thecurvedpartoftheblademust

bepointingupwardtowardtheinsideofthe

mowertoensurepropercutting.

2.Installthespringdiskandbladebolt.Thespring

diskconemustbeinstalledtowardthebolthead

(

Figure83).Torquethebladeboltto85-110ft-lb

(115-150N-m).

Figure83

1.SailAreaofBlade

4.BladeBolt

2.Blade

5.ConeT owardsBoltHead

3.SpringDisk

LevelingtheMower

PreparingtheMachine

1.Positionmoweronaatsurface.

2.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

56

Loading...

Loading...