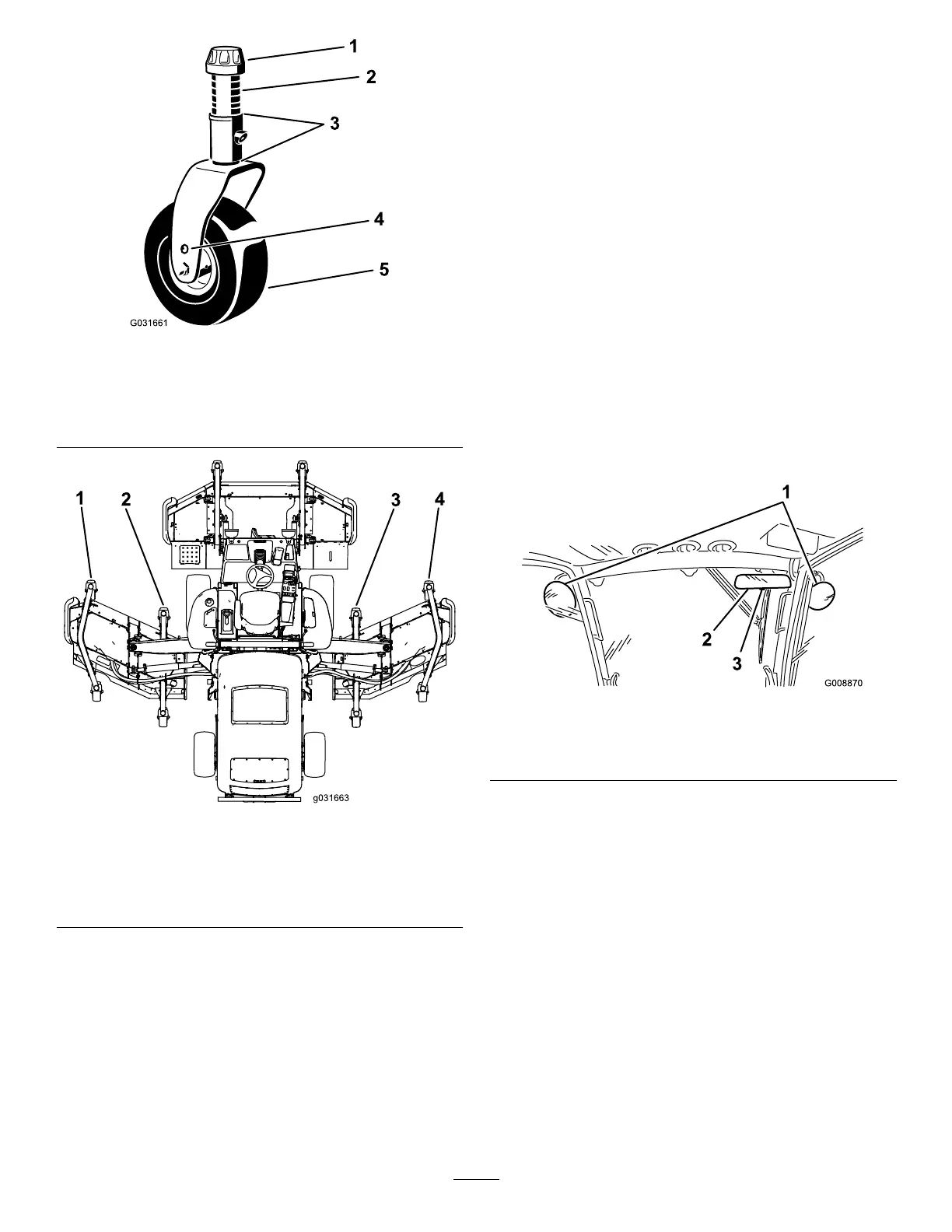

g031661

Figure28

1.Tensioningcap4.Topaxle-mountinghole

2.Spacers(6)5.Casterwheel

3.Shims(2topand2bottom)

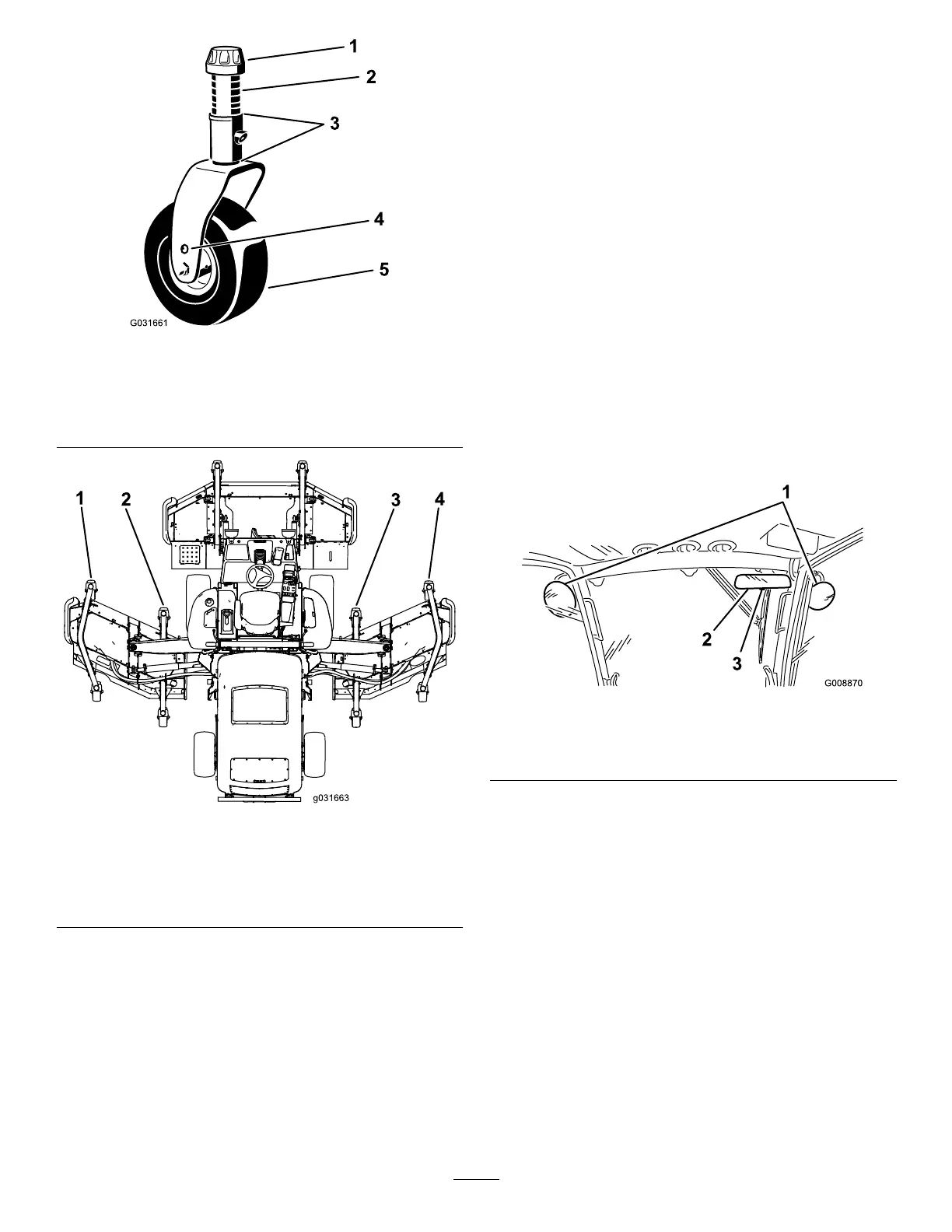

g031663

Figure29

1.Left,front,outsidecaster

arm

3.Right,front,insidecaster

arm

2.Left,front,insidecaster

arm

4.Right,front,outsidecaster

arm

6.Iftheinsideedgeisstilltoohigh,removean

additionalshimfromthebottomofthefront,

insidecasterarmofthewingcuttingunitand1

shimfromthefront,outsidecasterarmofthe

wingcuttingunit(Figure28andFigure29).

7.Iftheinsideedgeofthewingcuttingunitis

toolowrelativetotheoutsideedgeofthefront

cuttingunit,add1shim(1/8inch)tothebottom

ofthefront,insidecasterarmonthewingcutting

unit(Figure28andFigure29).

Note:Checkthemeasurementbetweenthe

outsideedgesofbothwingcuttingunitsandthe

insideedgeofthewingcuttingunittotheoutside

edgeofthefrontcuttingunitagain.

8.Iftheinsideedgeisstilltoolow,addanadditional

shimtothebottomoffront,insidecasterarm

ofthewingcuttingunitand1shimtothefront,

outsidecasterarmofthewingcuttingunit.

9.Oncethemowingheightmatchesattheedges

ofthefrontandwingcuttingunits,verifythatthe

cuttingunitunitpitchisstill7.6mm(0.3inch).

AdjustingtheMirrors

ForMachineswithaCab

Rear-ViewMirror

Whilesittingintheseat,adjusttherear-viewmirror

toattainthebestviewoutoftherearwindow.Pull

theleverrearwardtotiltthemirrortoreducethe

brightnessandglareoflight(Figure30).

g008870

Figure30

1.Side-viewmirrors

3.Lever

2.Rear-viewmirror

Side-ViewMirrors

Whilesittingintheseat,haveanotherpersonadjust

theside-viewmirrorstoattainthebestviewaround

thesideofthemachine(Figure30).

AimingtheHeadlights

Model31698Only

1.Loosenthemountingnutsandpositioneach

headlightsothatitpointsstraightahead.

Note:Tightenthemountingnutjustenoughto

holdtheheadlightinposition.

2.Placeaatpieceofsheetmetaloverthefaceof

theheadlight.

3.Mountamagneticprotractorontotheplate.

35

Loading...

Loading...