BladeMaintenance

BladeSafety

•Inspectthebladeperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthe

bladesorweargloves,andusecautionwhen

servicingtheblades.Onlyreplaceorsharpenthe

blades;neverstraightenorweldthem.

•Onmulti-bladedmachines,takecareasrotating

onebladecancauseotherbladestorotate.

CheckingforaBentBlade

Afterstrikingaforeignobject,inspectthemachine

fordamageandmakerepairsbeforerestartingand

operatingtheequipment.Torqueallthespindle-pulley

nutsto176to203N·m(130to150ft-lb).

1.Raisethecuttingunit.

2.Performthepre-maintenanceprocedure;refer

toPre-MaintenanceProcedures(page63).

3.Blockthecuttingunittopreventitfrom

accidentallyfalling.

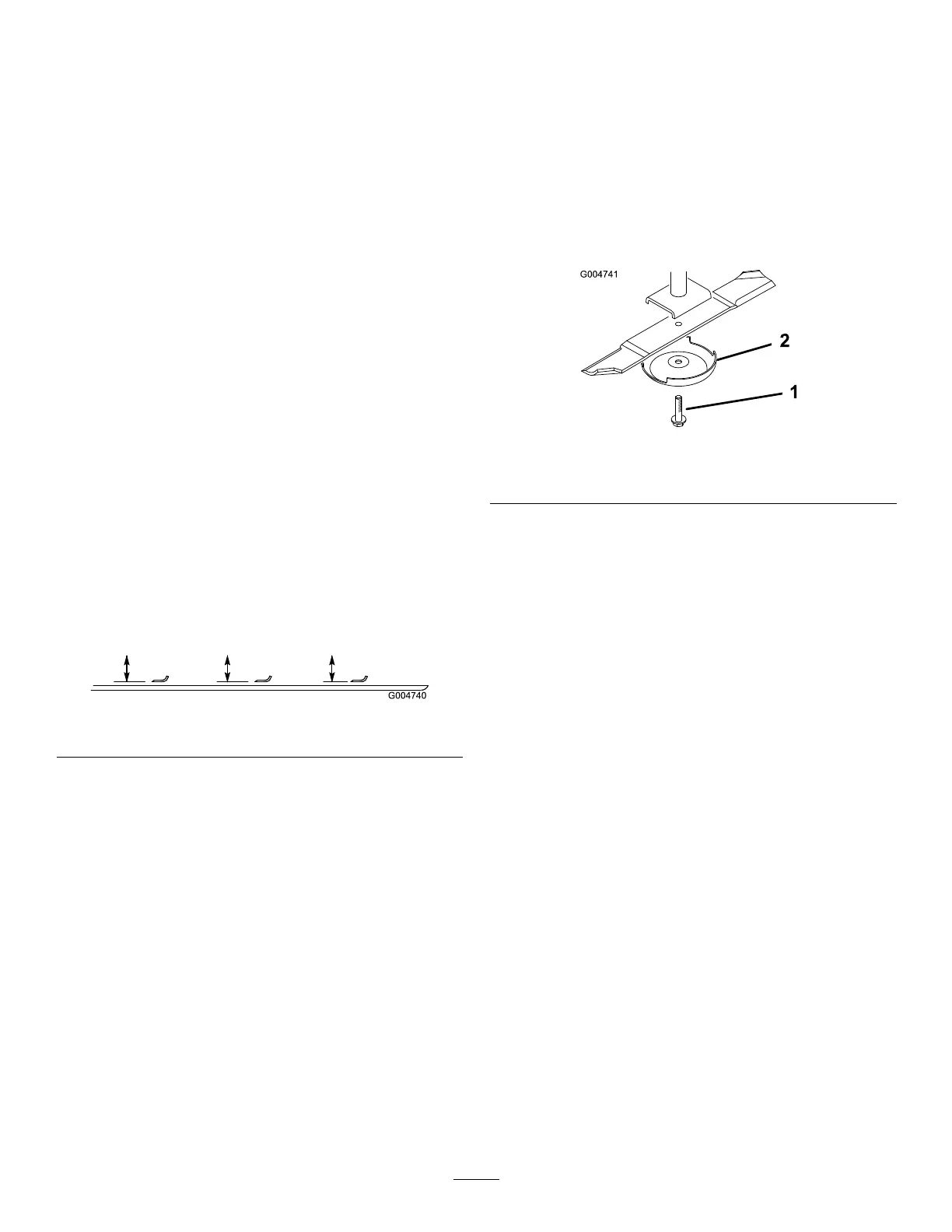

4.Rotatethebladeuntiltheendsfaceforwardand

backward,andmeasurefromtheinsideofthe

cuttingunittothecuttingedgeatthefrontofthe

blade(Figure140).

Note:Recordthisdimension.

g004740

Figure140

5.Rotatetheoppositeendofthebladeforward

andmeasurebetweenthecuttingunitand

cuttingedgeofthebladeatthesameposition

asinstep4.

Note:Thedifferencebetweenthedimensions

obtainedinsteps4and5mustnotexceed3mm

(1/8inch).Ifthedimensionexceeds3mm(1/8

inch),thebladeisbentandmustbereplaced;

refertoRemovingandInstallingtheCutting-Unit

Blade(s)(page92).

RemovingandInstalling

theCutting-UnitBlade(s)

Replacethebladeifithitsasolidobject,isout

ofbalance,orisbent.AlwaysusegenuineT oro

replacementbladestoensuresafetyandoptimum

performance.

1.Parkthemachineonalevelsurface,raisethe

cuttingunittothetransportposition,engagethe

parkingbrake,shutofftheengine,andremove

thekey.

Note:Blockthecuttingunittopreventitfrom

accidentallyfalling.

2.Grasptheendofthebladeusingaragor

thickly-paddedglove.

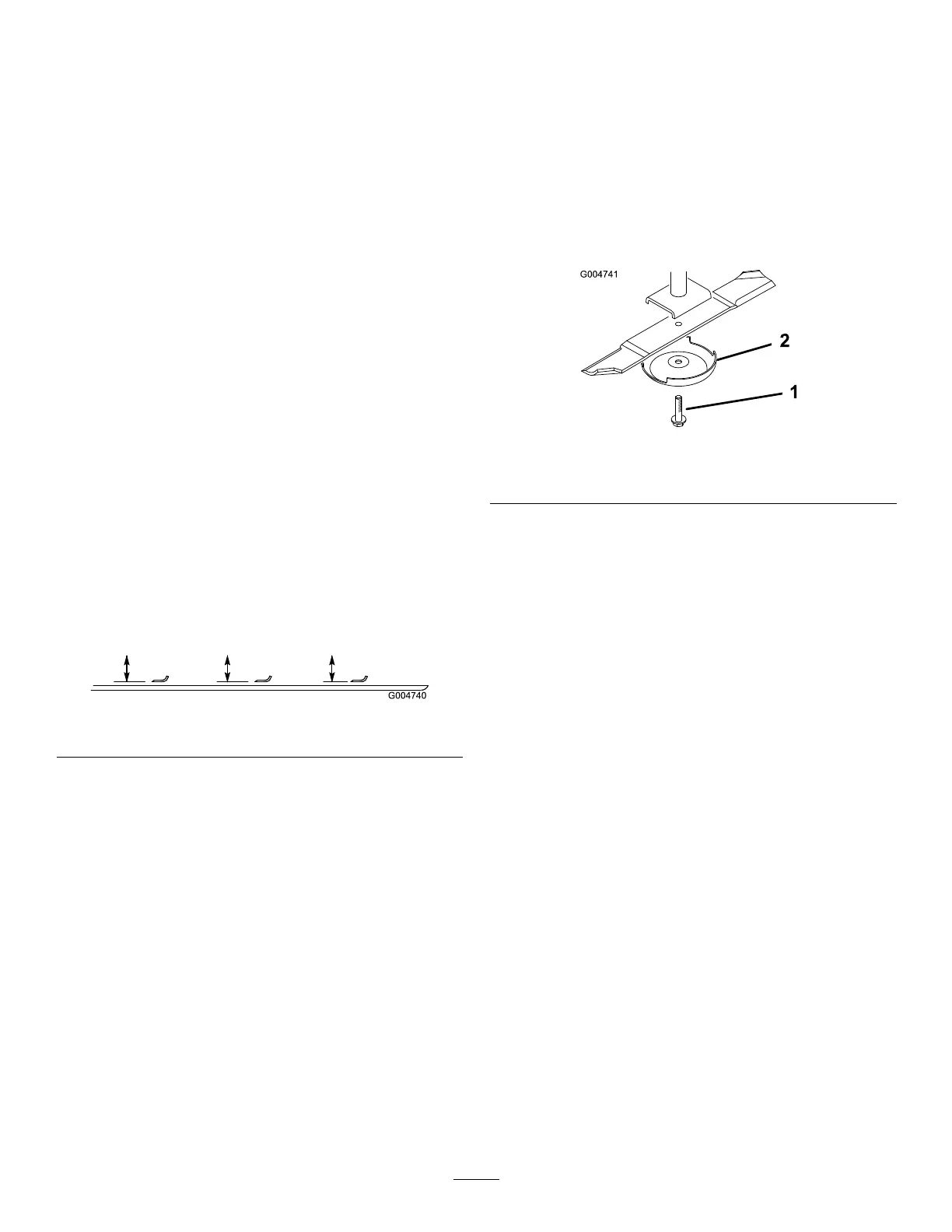

3.Removethebladebolt,anti-scalpcup,and

bladefromthespindleshaft(Figure141).

g004741

Figure141

1.Bladebolt2.Anti-scalpcup

4.Installtheblade,anti-scalpcup,andbladebolt

andtightenthebladeboltto115to149N∙m(85

to110ft-lb).

Important:Thecurvedpartoftheblade

mustbepointingtowardtheinsideofthe

cuttingunittoensurepropercutting.

Note:Afterstrikingaforeignobject,torqueall

spindle-pulleynutsto115to149N∙m(85to110

ft-lb).

92

Loading...

Loading...