ElectricalSystem

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

CheckingtheBattery

Condition

ServiceInterval:Every50hours

Important:Beforeweldingonthemachine,

disconnectthenegativecablefromthebatteryto

preventdamagetotheelectricalsystem.Also,

youmustdisconnecttheengine,InfoCenter,

andmachinecontrollersbeforeweldingonthe

machine.

Note:Keeptheterminalsandtheentirebatterycase

clean,becauseadirtybatterydischargesslowly.T o

cleanthebattery,washtheentirecasewithasolution

ofbakingsodaandwater.Rinsewithclearwater.

Coatthebatterypostsandcableconnectorswith

Grafo112X(skin-over)grease(ToroPartNo.505-47)

orpetroleumjellytopreventcorrosion.

LocatingtheFuses

Important:Ifyouareinstallinganauxiliary

accessorytothemachine,theonlyapproved

locationstosourcepowerareatthetraction-unit

fuseblock(Figure104)orthecab-fuseblock

(Figure106).Amaximumof10Aisavailablefrom

eitherlocation.ContactyourauthorizedToro

distributorforassistance.

Note:Shutofftheengineandremovethekeybefore

removingthefuses.

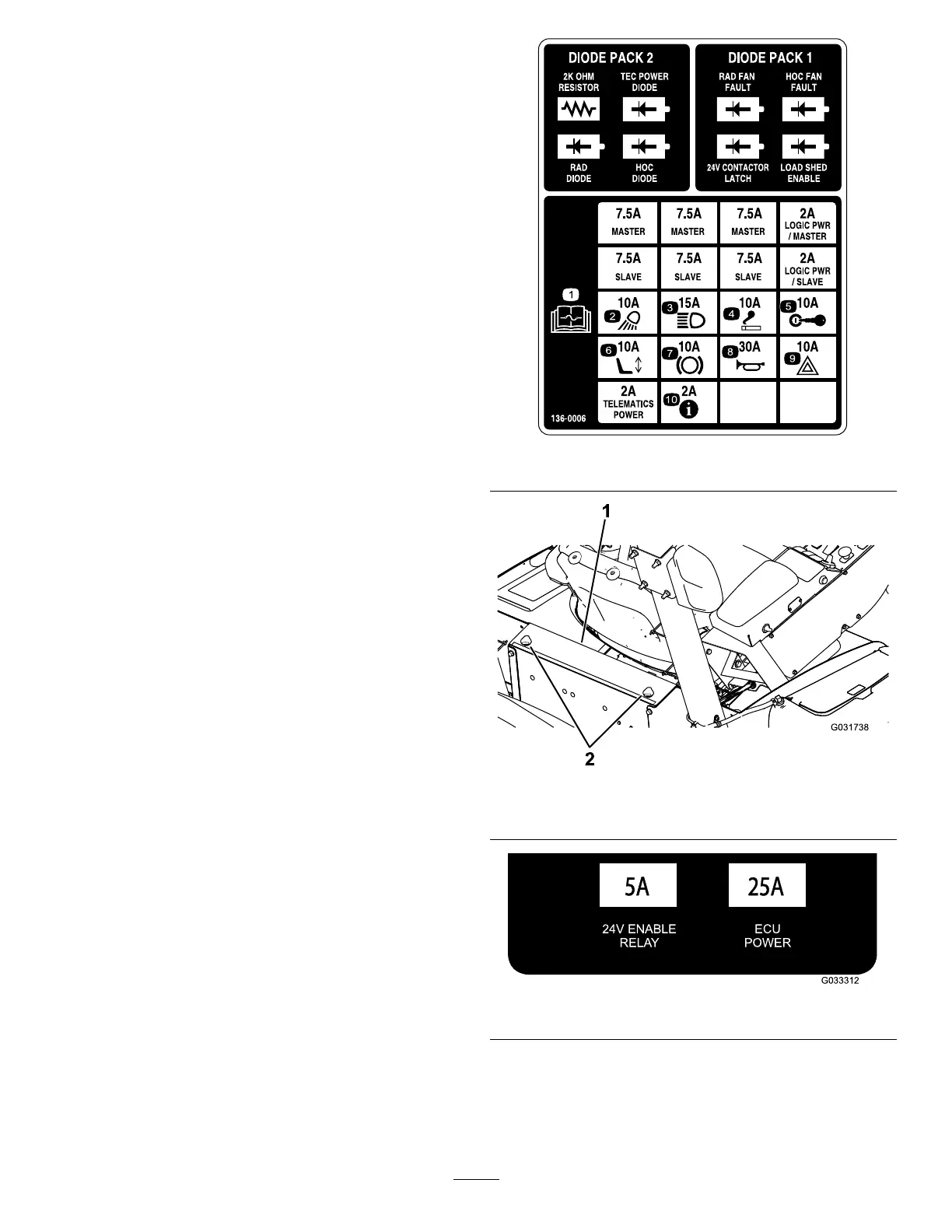

Thetraction-unitfuses(Figure100)arelocatedinthe

power-centerconsolebehindtheseat(Figure101).

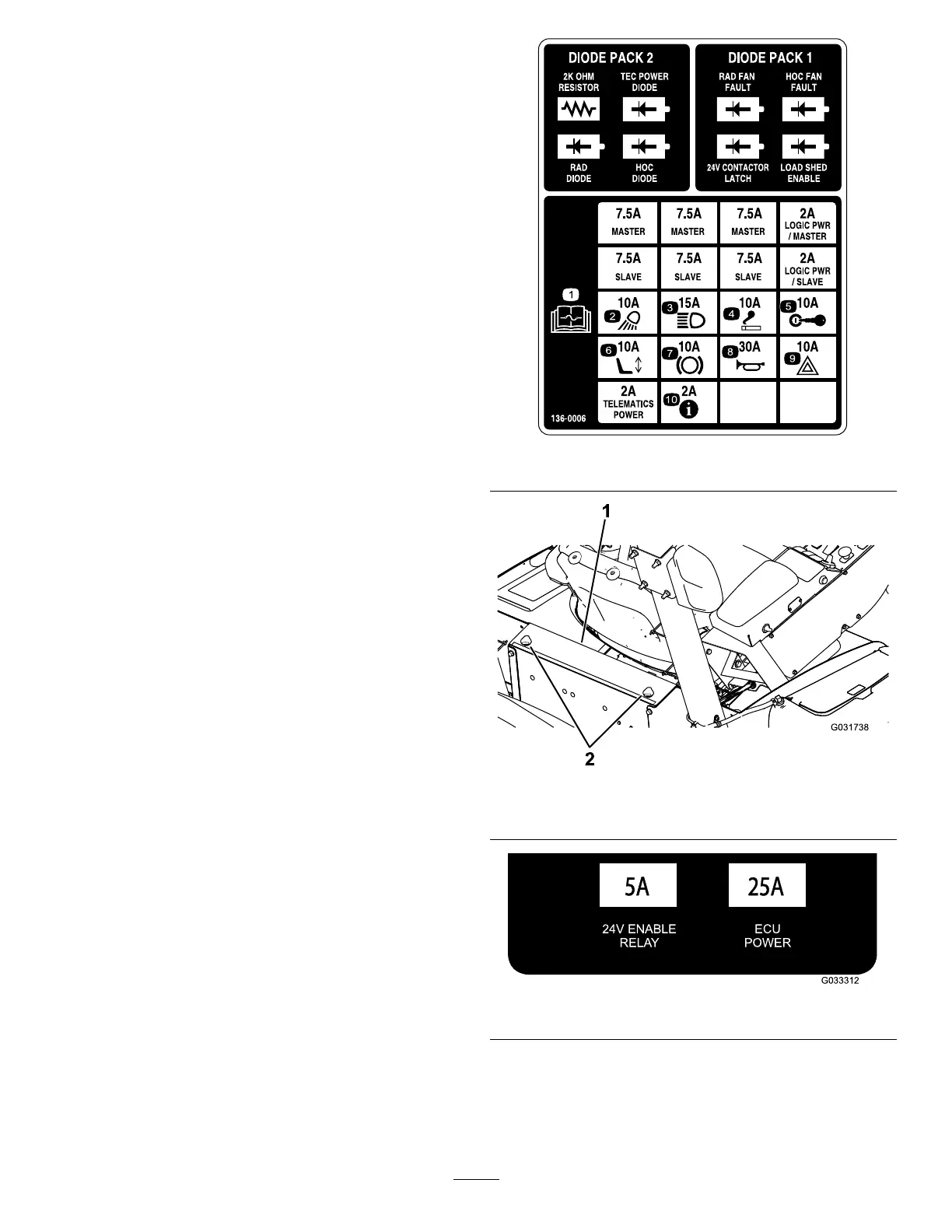

Additionaltraction-unitfuses(Figure102)arelocated

ontherear,rightsideofthemachine(Figure103).

decal136-0006

Figure100

g031738

Figure101

1.Power-centerconsole2.Knobs

g033312

Figure102

74

Loading...

Loading...