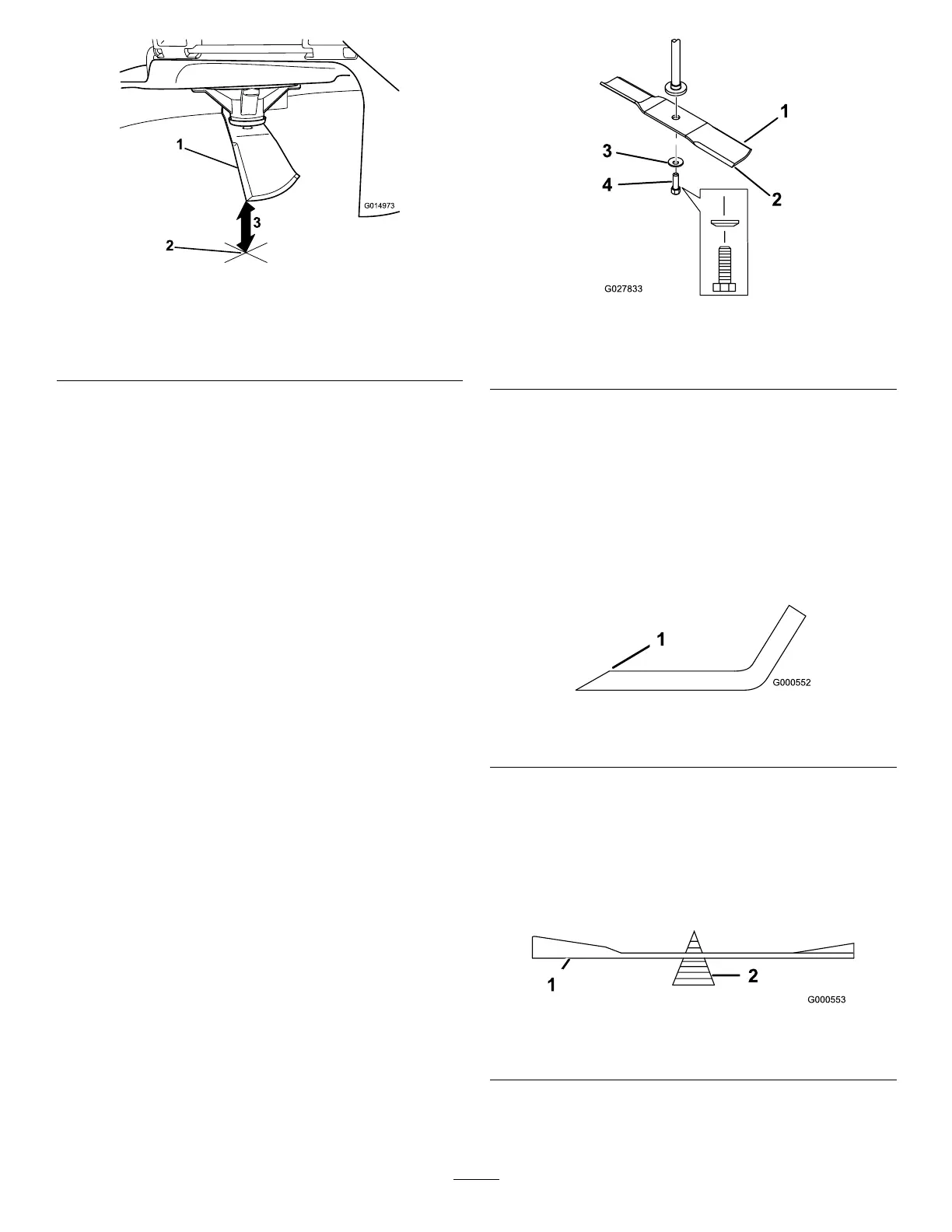

g014973

Figure 62

1. Opposite blade edge (in position for measuring)

2. Level surface

3. Second measured distance between blade and surface (B)

A. If the dif ference between A and B is greater

than 3 mm (1/8 inch), replace the blade with

a new blade; refer to Removing the Blades

( page 43 ) and Installing the Blades ( page

44 ) .

Note: If a bent blade is replaced with a

new blade, and the dimension obtained

continues to exceed 3 mm (1/8 inch), the

blade spindle could be bent. Contact an

Authorized Service Dealer for service.

B. If the variance is within constraints, move to

the next blade.

6. Repeat this procedure on each blade.

Removing the Blades

Replace the blades if they hit a solid object, or if the

blade is out of balance or bent.

1. Hold the blade end using a rag or thickly padded

glove.

2. Remove the blade bolt, curved washer , and

blade from the spindle shaft ( Figure 63 ).

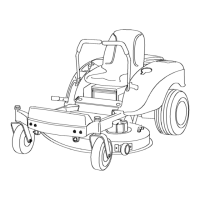

g027833

Figure 63

1. Sail area of the blade 3. Curved washer

2. Blade 4. Blade bolt

Sharpening the Blades

1. Use a le to sharpen the cutting edge at both

ends of the blade ( Figure 64 ).

Note: Maintain the original angle.

Note: The blade retains its balance if the same

amount of material is removed from both cutting

edges.

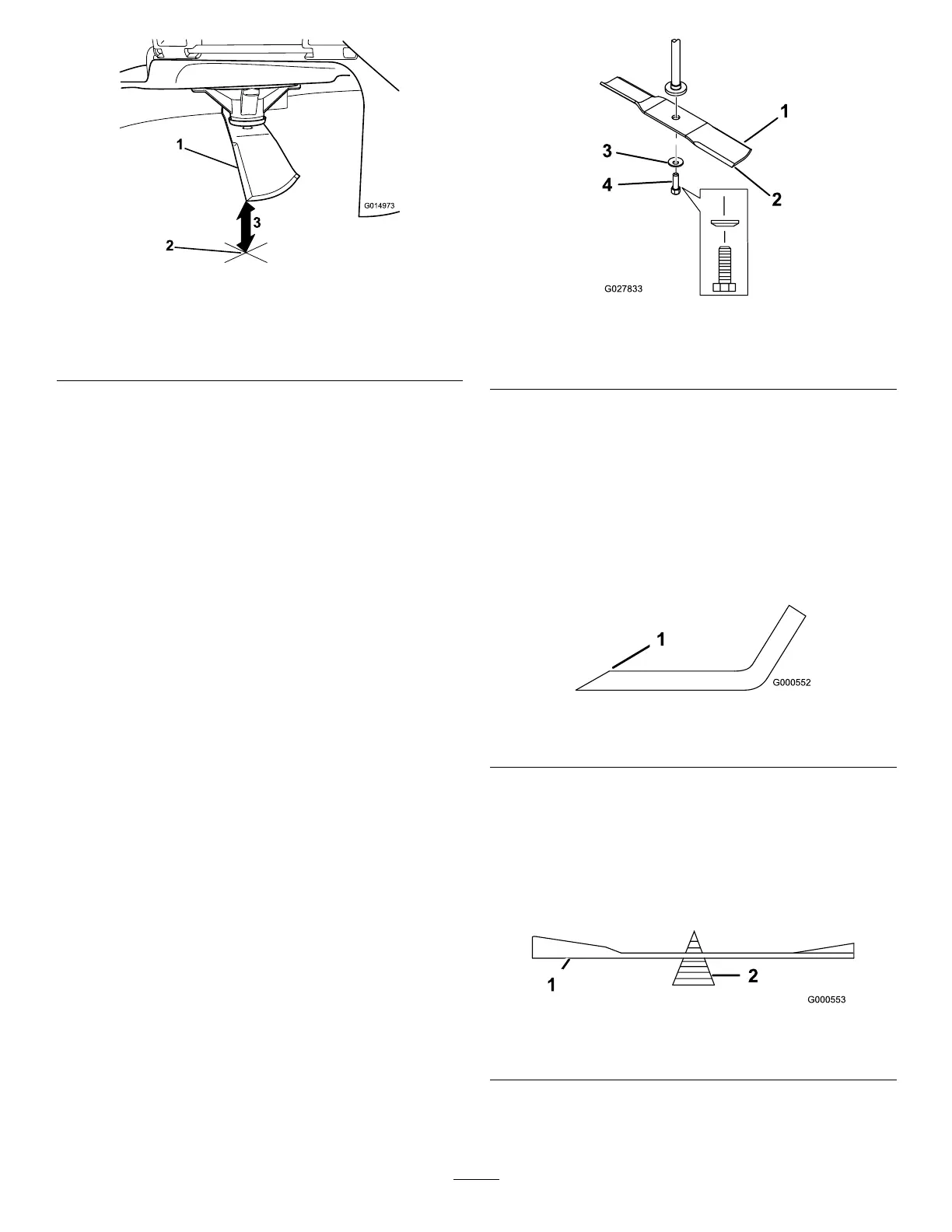

g000552

Figure 64

1. Sharpen at original angle.

2. Check the balance of the blade by putting it on a

blade balancer ( Figure 65 ).

Note: If the blade stays in a horizontal position,

the blade is balanced and can be used.

Note: If the blade is not balanced, le some

metal of f the end of the sail area only ( Figure 64 ).

g000553

Figure 65

1. Blade 2. Balancer

3. Repeat this procedure until the blade is

balanced.

43

Loading...

Loading...