CHAIN

INSPECTION

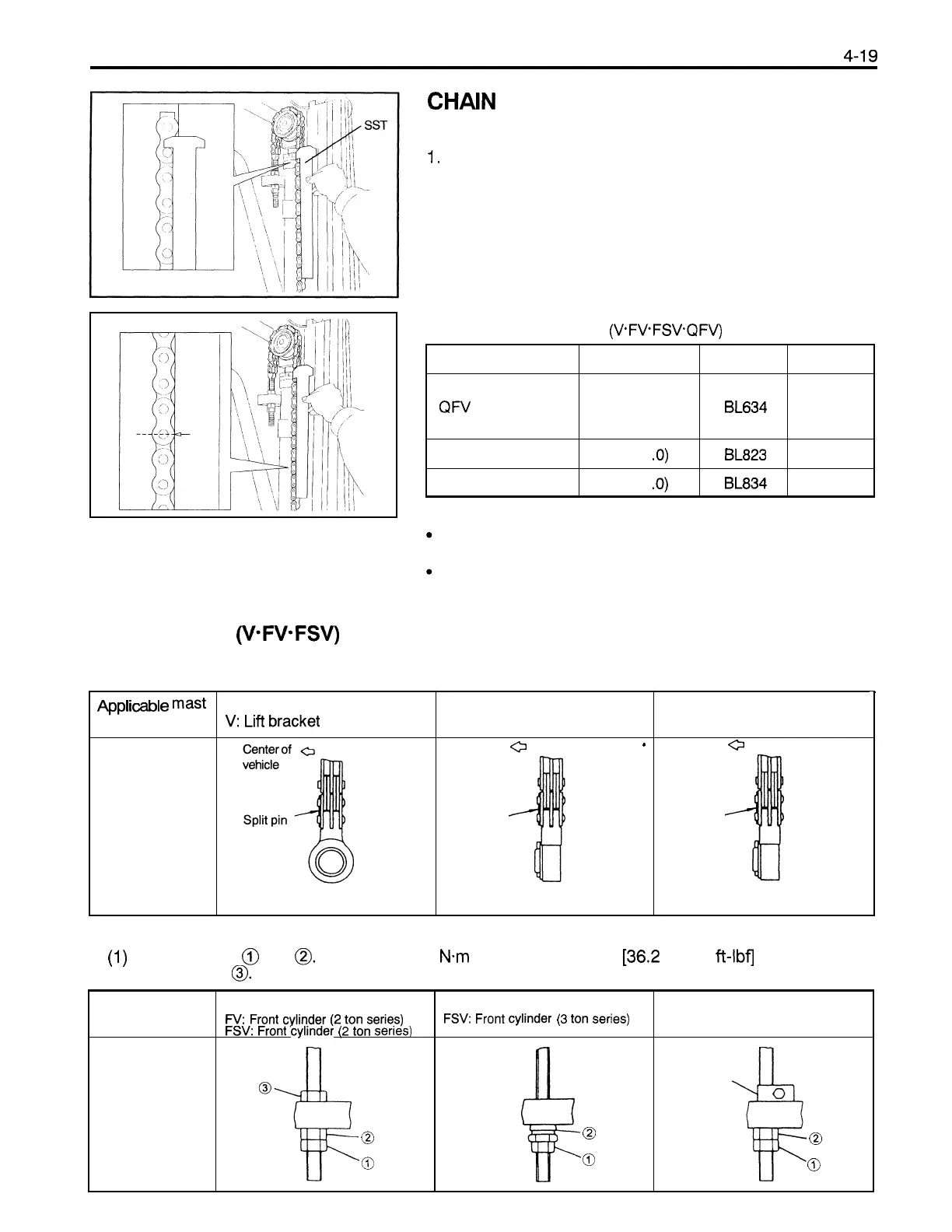

1.

lnspect the chain elongation according to the following

procedure:

SST

09631

-

22000

-

71

(1) Since the SST measurement line varies with the chain type,

set the corresponding line on the chain as illustrated.

(2)

Check the number of the chain to be inspected, and

check the pin center position.

If the pin center is at the arrow mark on the chain gauge,

it is the limit.

Chain Link Pitch Standard (V.FV.FSV.QFV)

Note:

Perform measurement without removing the chain

from the vehicle.

lnspect elongation over the entire chain length since

it may be localized.

REASSEMBLY O/.FV0FSV)

1.

Installing direction

Vehicle model

2 ton series

QFV inner and

middle chain

3

ton series

QFV outer chain

Type

BL634

BL823

BL834

Pitch mm (in)

1 9.05 (0.7500)

25.4

(1

.O)

25.4 (1 .O)

2.

Chain adjusting nut tightening order

(1)

Tighten nuts

@I

and

0.

T

=

49.0

-

78.0

N-m

(500

-

800

kgf

-

cm)

[36.2

-

57.9

ft-lbfl

(2)

Tighten nut

0.

Chain No.

60

80

80

mast

and portion

Sketch

V: Lift

bracket

Install with the split pin on the

vehicle center side.

Applicable mast and

portion

Sketch

FV: Lift bracket

FSV: Lift bracket

Outside of

0

'

vehicle

Split pin

Install with the split pin on the

vehicle outside.

FV: Front cylinder

(3

ton series)

FSV: Front cylinder

(3

ton series)

0

0

V: Outer mast

FV:

Front

cylinder

(2

ton series)

FSV: ~~~~t cylinder

(2

ton series)

0

0

-

FSV: Inner mast

Rear of

0

vehicle

Split pin

Install with the split pin on the

vehicle rear side.

FSV: Outer mast

Clamp

0

0

Loading...

Loading...