48

AC-SVX001A-EN

Operating Principles

This section contains an overview of the operation and

maintenance of units equipped with UC800 control

systems. It describes the overall operating principles of

the Ascend™ ACRA design.

Refrigeration Circuits

Each unit has two refrigerant circuits, with one rotary

screw compressor per circuit. Each refrigerant circuit

includes a compressor suction and discharge service

valve, liquid line shutoff valve, removable core filter,

liquid line sight glass with moisture indicator, charging

port and an electronic expansion valve. Fully

modulating compressors and electronic expansion

valves provide variable capacity modulation over the

entire operating range. Lower condensing

temperatures and higher suction temperatures along

with more efficient compressors and fans result in the

premium efficiency level.

Refrigeration Cycle

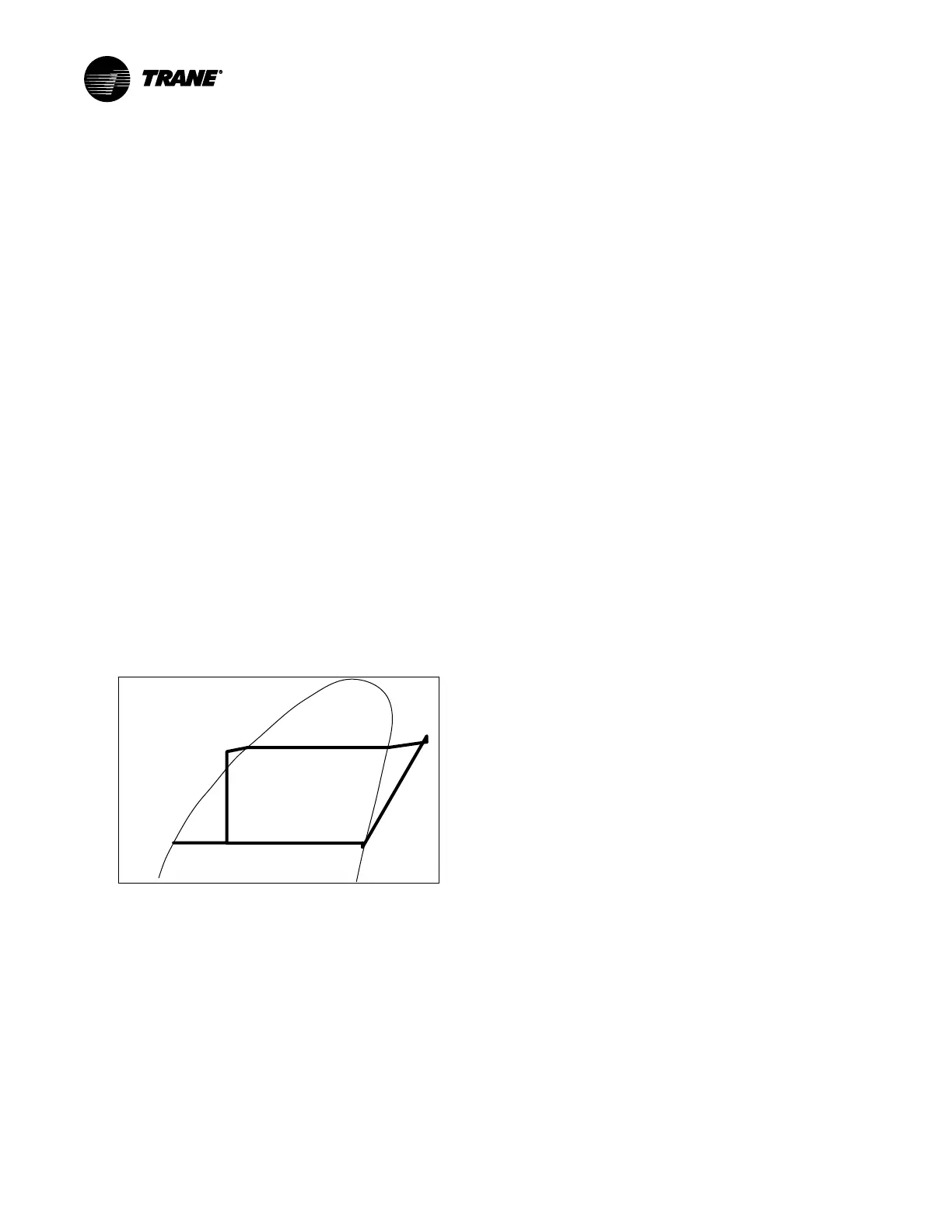

The refrigeration cycle of the chiller is represented in

the pressure enthalpy diagram shown in figure below.

Key state points are indicated on the figure. The cycle

for the full load AHRI design point is represented in the

plot.

Figure 24. Pressure-enthalpy (P-h) diagram

The chiller uses a shell and tube evaporator design

with refrigerant evaporating on the shell side and water

flowing inside tubes having enhanced surfaces (states

4 to 1). The suction lines are designed to minimize

pressure drop.(states 1 to 1b). The compressor is a

twin-rotor helical rotary compressor designed similarly

to the compressors offered in other Trane Screw

Compressor Based Chillers (states 1b to 2). The

discharge lines include a highly efficient oil separation

system that removes 99.8% of the oil from the

refrigerant stream going to the heat exchangers (states

2 to 2b). De-superheating, condensing and sub-cooling

is accomplished in a fin and tube air cooled heat

exchanger where refrigerant is condensed in the tube

(states 2b to 3b). Refrigerant flow through the system is

balanced by an electronic expansion valve (states 3b to

4).

Refrigerant R-134a

The Ascend™ ACRA chiller uses environmentally

friendly R-134a. Trane believes responsible refrigerant

practices are important to the environment, our

customers, and the air conditioning industry. All

technicians who handle refrigerants must be certified.

The Federal Clean Air Act (Section 608) sets forth the

requirements for handling, reclaiming, recovering and

recycling of certain refrigerants and the equipment that

is used in these service procedures. In addition, some

states or municipalities may have additional

requirements that must also be adhered to for

responsible management of refrigerants. Know the

applicable laws and follow them.

Refrigerant R-134a is a medium pressure refrigerant. It

may not be used in any condition that would cause the

chiller to operate in a vacuum without a purge system.

Ascend™ ACRA is not equipped with a purge system.

Therefore, the chiller may not be operated in a

condition that would result in a saturated condition in

the chiller of –15°F (-26°C) or lower.

Refrigerant R-134a requires the use of specific POE oils

as designated on the unit nameplate.

IImmppoorrttaanntt:: Use only R-134a and Trane Oil 00311 (bulk)/

00315 (1gal)/00317 (5gal) .

Compressor and Oil System

The rotary screw compressor is variable Vi (variable

pressure ratio) semi-hermetic, direct drive with

capacity control via a variable speed drive, rolling

element bearings, differential refrigerant pressure oil

pump and oil heater. To maximize efficiency, the

variable Vi compressor is controlled to one of two

possible states depending on the chiller system

operating point and to provide ease of starting. The

motor is a suction gas cooled, hermetically sealed,

permanent magnet motor. An oil separator is provided

separately from the compressor. Oil filtration is

provided internal to the compressor. Check valves in

the compressor discharge and lube oil system are also

provided.

Condenser and Fans

Air-cooled condenser coils have aluminum fins

mechanically bonded to internally finned seamless

aluminum tubing. The tubing is a long life alloy

designed to deliver corrosion performance that meets

or exceeds microchannel coils. The condenser coil has

Loading...

Loading...