80

AC-SVX001A-EN

intermediate oil.

2. Observe liquid line sight glass on EXV. If liquid line

sight glass has bubbles measure the subcooling

entering the EXV. Subcooling should always be

greater than 10°F.

3. Inspect the entire system for unusual operation.

4. Inspect the condenser coils for dirt and debris. If the

coils are dirty, see Condenser Coil Corrosion

Protection Inspection section of Maintenance

chapter.

NNOOTTIICCEE

CCooiill DDaammaaggee!!

UUssee ooff ddeetteerrggeennttss ccoouulldd ccaauussee ddaammaaggee ttoo ccooiillss..

DDoo nnoott uussee ddeetteerrggeennttss ttoo cclleeaann ccooiillss.. UUssee cclleeaann

wwaatteerr oonnllyy..

Monthly

1. Perform all weekly maintenance procedures.

2. Record the system subcooling.

Annual

1. Perform all weekly and monthly procedures

2. Check oil sump oil level while unit is off. See Oil

Sump Level Check section of Maintenance chapter.

3. Perform pH test of drive cooling fluid. See pH Test

section of Maintenance chapter.

4. Have a qualified laboratory perform a compressor

oil analysis to determine system moisture content

and acid level.

5. Contact a Trane service organization to leak test the

chiller, to check operating and safety controls, and

to inspect electrical components for deficiencies.

6. Clean and repaint any areas that show signs of

corrosion.

7. Clean the condenser coils. See Condenser Coil

Corrosion Protection Inspection section of

Maintenance chapter.

NNOOTTIICCEE

CCooiill DDaammaaggee!!

UUssee ooff ddeetteerrggeennttss ccoouulldd ccaauussee ddaammaaggee ttoo ccooiillss..

DDoo nnoott uussee ddeetteerrggeennttss ttoo cclleeaann ccooiillss.. UUssee cclleeaann

wwaatteerr oonnllyy..

Refrigerant and Oil Charge

Management

Proper oil and refrigerant charge is essential for proper

unit operation, unit performance, and environmental

protection. Only trained and licensed service personnel

should service the chiller.

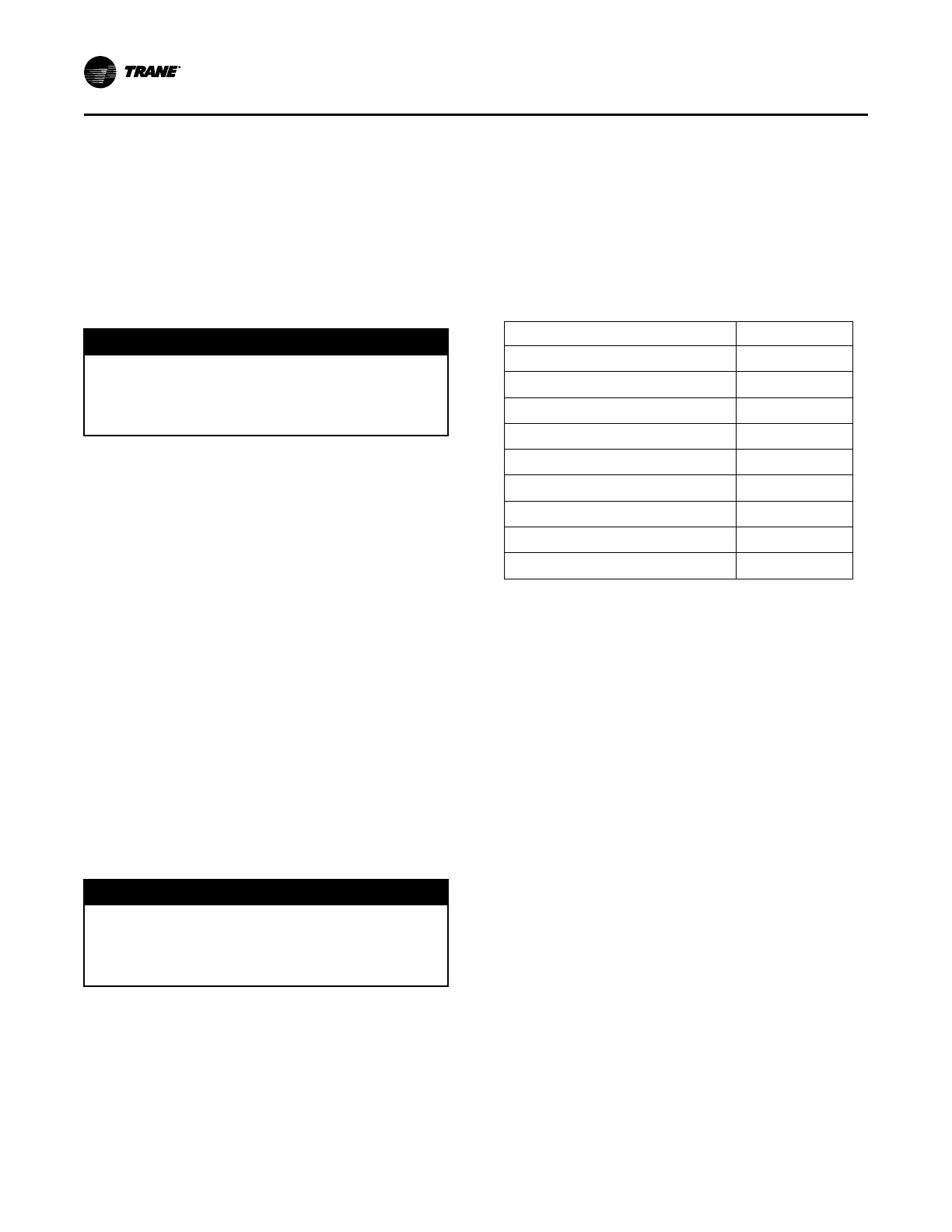

The following table lists baseline measurements for

chillers running at AHRI standard operating conditions.

If chiller measurements vary significantly from values

listed below, problems may exist with refrigerant and

oil charge levels. Contact your local Trane office.

NNoottee:: Low temperature applications units will have

values that vary from the following table.

Contact your local Trane office for more

information.

Table 25. Typical baselines (AHRI conditions)

Measurement Baseline

Evaporator Pressure 51 psia

Evaporator Approach

3.4°F

EXV Position (150 to 200T units) 45-50% open

EXV Position (225 to 300T units) 61-64% open

Evaporator ΔT - entering

54°F

Evaporator ΔT - leaving

44°F

Discharge Superheat

16.5°F

Condenser Pressure

212 psia

Subcooling

10 to 20°F

Lubrication System

The lubrication system has been designed to keep

most of the oil lines filled with oil as long as there is a

proper oil level in the oil sump.

Oil Sump Level Check

The oil level in the sump can be measured to give an

indication of the system oil charge. Follow the

procedures below to measure the level.

1. Run the unit as near to full load as possible for a

minimum of 30 minutes. For an accurate reading,

40 or more minutes at full load with normal/steady

discharge superheat readings and no limits/

warnings is recommended. Assessing oil charge

after running at minimum or low loads may lead to

an inaccurate reading.

2. Cycle the compressor off line.

3. Let the chiller sit (powered, but off line) to allow the

oil separator heater to boil off the refrigerant that

may be in the oil separator. An initial assessment of

the oil separator level may be made after 30

minutes of heater ON dwell time, but oil charge

adjustments should not be made without allowing

the oil heaters to run for a minimum of 4 hours.

MMaaiinntteennaannccee

Loading...

Loading...