AC-SVX001A-EN

81

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

OOppeerraattiinngg ccoommpprreessssoorrss wwiitthh sseerrvviiccee vvaallvveess ooppeenn

wwiillll rreessuulltt iinn sseevveerree ooiill lloossss aanndd eeqquuiippmmeenntt

ddaammaaggee..

NNeevveerr ooppeerraattee tthhee ccoommpprreessssoorr wwiitthh tthhee ssiigghhtt ggllaassss

sseerrvviiccee vvaallvveess ooppeenneedd.. CClloossee tthhee vvaallvveess aafftteerr

cchheecckkiinngg tthhee ooiill lleevveell..

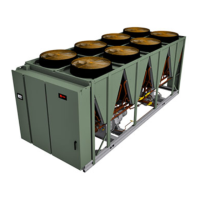

4. Attach a 3/8” or 1/2” hose with a sightglass in the

middle to the oil sump service valve (1/4” flare) and

the oil separator service valve (1/4” flare). See the

following figure for valve locations.

NNoottee:: High pressure rated clear hose with

appropriate fittings can help speed up the

process. Hose must be rated to withstand

system pressures as found on unit nameplate.

Figure 61. Oil service valves

To Oil Separator Service Valve

Oil Service Valve

5. After the unit is off line for 30 minutes, move the

sightglass along the side of the oil sump.

6. The nominal oil level from the bottom of the oil

separator should be as shown in the following table

and figure. Depending on running conditions and

oil heater dwell time, some deviation from nominal

levels is expected.

IImmppoorrttaanntt:: If level is less than 4 inches from the

bottom of the oil separator, contact

your local Trane office.

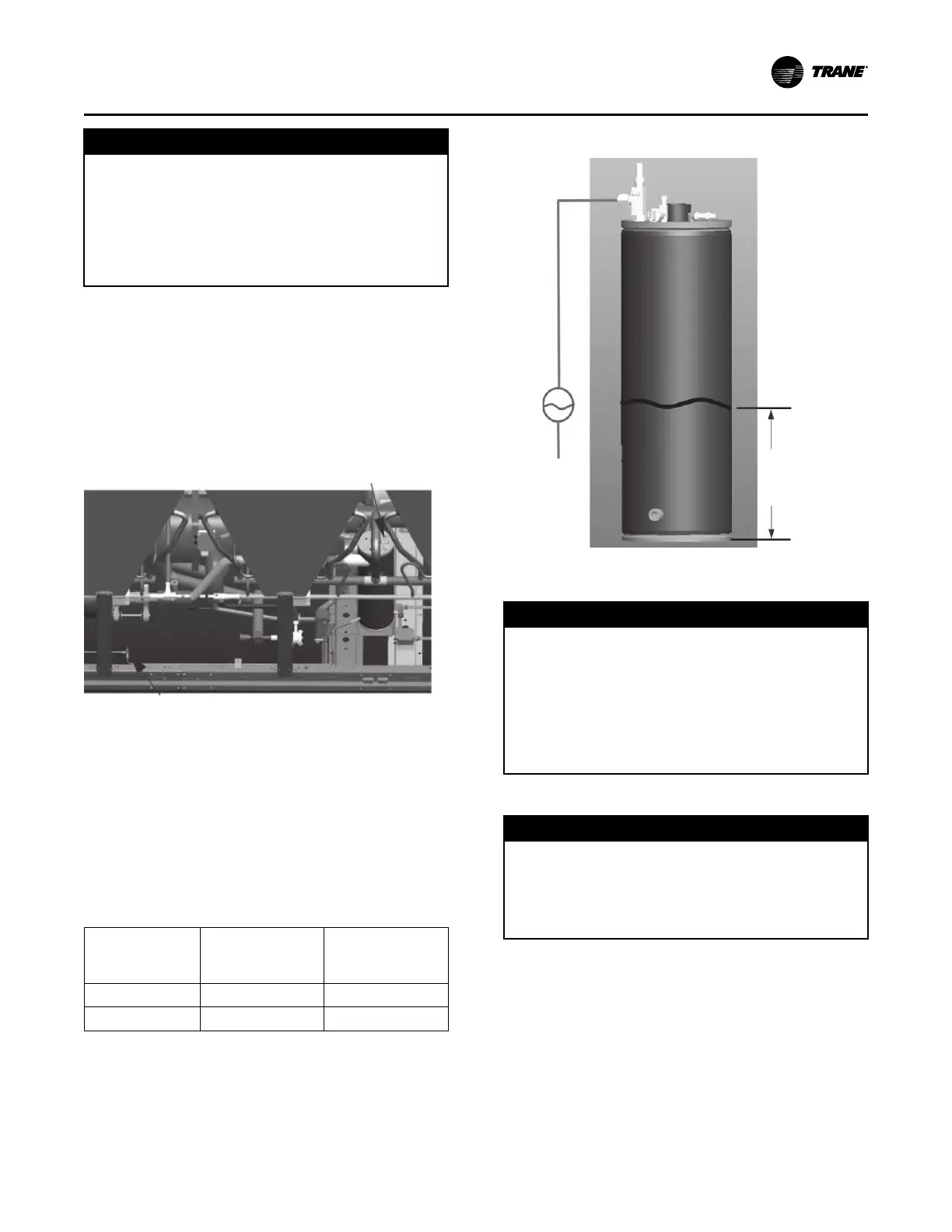

Unit Size

(tons)

Oil Separator

Size

(in)

Nominal Oil

Charge Height

(in)

150 to 200 10 9.0

225 to 300 12 8.5

Figure 62. Nominal oil level

Nominal oil level:

10 in oil sep: 9.0 in

12 in oil sep: 8.5 in

To Oil Separator

Service Valve

Drive Cooling System

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

UUssee ooff uunnaapppprroovveedd fflluuiiddss,, oorr ddiilluuttiioonn ooff aapppprroovveedd

fflluuiidd ccoouulldd rreessuulltt iinn ccaattaassttrroopphhiicc eeqquuiippmmeenntt

ddaammaaggee..

UUssee oonnllyy TTrraannee HHeeaatt TTrraannssffeerr FFlluuiidd PP//NN CCHHMM0011002233..

TThhiiss fflluuiidd iiss aa ddiirreecctt uussee ccoonncceennttrraattiioonn aanndd iiss nnoott

ttoo bbee ddiilluutteedd.. DDoo nnoott ttoopp ooffff wwiitthh wwaatteerr oorr aannyy

ootthheerr fflluuiidd..

Service Intervals

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss ccoouulldd rreessuulltt iinn

eeqquuiippmmeenntt ddaammaaggee..

DDrriivvee ccoooolliinngg fflluuiidd aanndd ssttrraaiinneerr mmuusstt bbee sseerrvviicceedd

eevveerryy ffiivvee ((55)) yyeeaarrss..

• Every (5) years, contact your local Trane office to

service drive fluid and strainer.

• On a yearly basis, a fluid pH test should be

performed.

Unit Diagnostics

An improperly filled drive cooling system (either low

fluid level or entrapped air in the circuit) can result in

the AFD drive overheating. This condition may result in

the following diagnostic(s):

MMaaiinntteennaannccee

Loading...

Loading...