Installation - Mechanical

UNT-SVX041D-EN 19

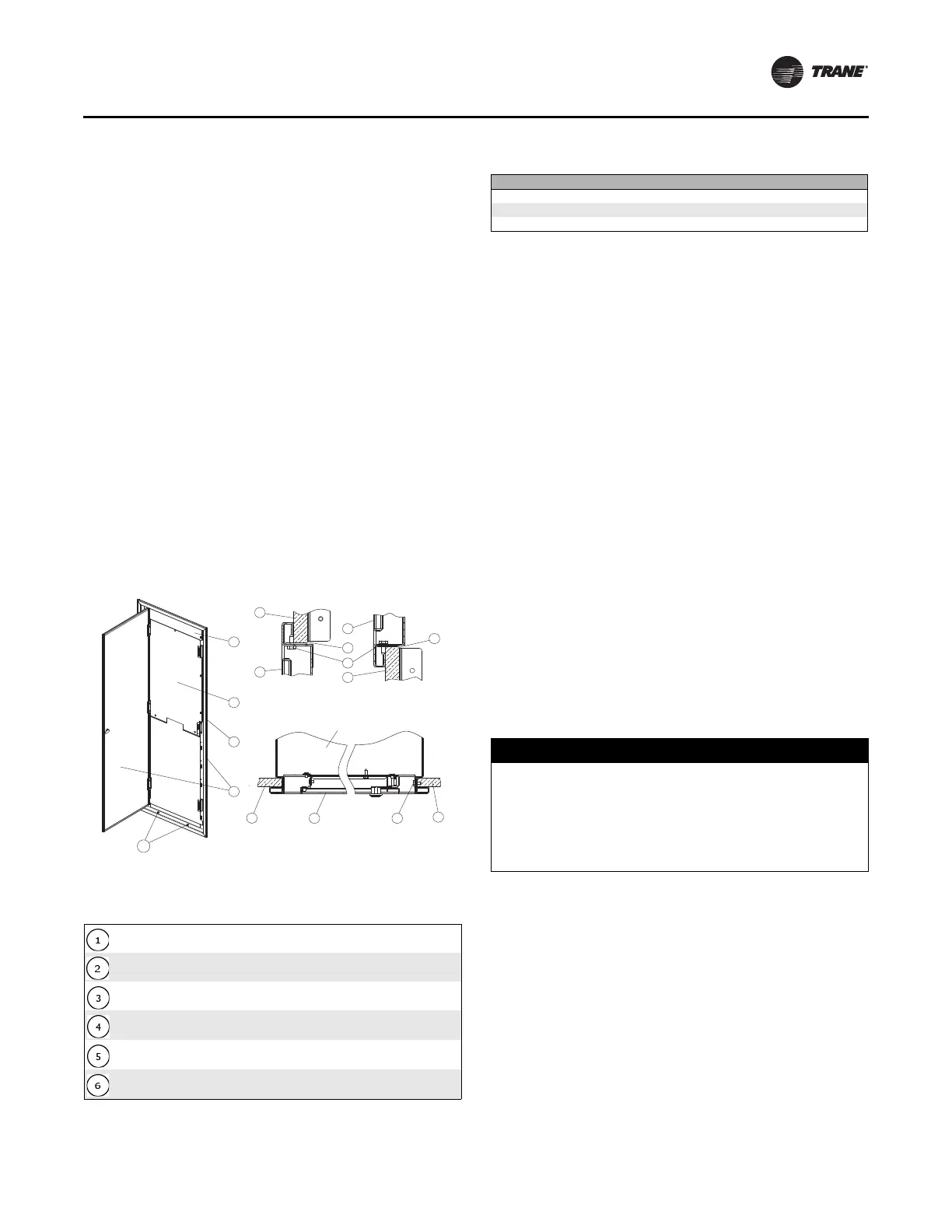

Return Air Panel (Perimeter Return Air

Panel) with Cover

1. If the drywall has not been installed flush with the outer

edge of the collar on the unit and if the gap between the

inner surface of the drywall and the outer edge of the

collar exceeds one-half inch, the opening will have to

be sleeved (not provided by the factory).

2. The covers are shipped with the unit. Remove the

control box and fan cover from the unit. Insert the

return air panel and install six sheet metal screws as

shown in Figure 5. Do not over-tighten the screws as

this might distort the door frame.

3. Insert the fan cover into the frame of the return air door

with 45 degree flanges and then secure it by fitting

sheet metal screws in the frame.

4. Mount the control box cover in the same way as the

motor cover.

Note: This type of return air door requires a 1 inch deep

collar on the front of the fan coil unit. Drywall can

be attached directly to the front of the unit after

mounting this door.

Thermostat Installation

Unit mounted thermostat

Connect the wires from the thermostat to the wire harness

inside the electrical box using the plug provided or by

connecting directly to the terminal strip on the CSTI board.

Mount the thermostat to the drywall using a standard mud

flap or control box.

Remote mounted thermostat

Run low voltage wires from the 24V thermostat on the wall

back to the thermostat plug inside the unit. Ensure that the

guidelines described in the “Power Connection,” section

on page 28 are followed when installing thermostats.

Typical Installation Sequence

Typical Fan Coil Unit

1. A rectangular opening is made in the floor slab, usually

sleeved before pouring the floor. Refer to the catalog or

submittals for sizes.

2. Rotate the unit from the horizontal position to vertical

so that the bottom end of the risers insert into the

expanded end of the risers on the unit below.

Approximately two inches is allowed in the riser length

for the depth of the insertion. Shim the unit plumb.

3. Before making the joint, ensure that the run outs from

the supply and return risers are centered in the slots in

the cabinet. If this is not done there is considerable risk

of distorting the run out when the riser expands or

contracts causing the run out to deform on the edge of

the slot in the cabinet sheet metal. Also ensure that all

riser stub outs are at 90° to the cabinet so that the drain

hose is not kinked and the run-outs do not get

deformed.

4. Riser anchoring is required for two main purposes. The

risers are anchored to the floor slab at one or more

points in the height of the building so that they do not

slip down under gravity. The second reason is to

spread the expansion in opposite directions from the

anchor point. If there are expansion loops included in

Figure 5. Return air panel - framed out drywall

Table 7. Return air panel - framed out drywall callouts

Return air door

Fan cover for air blockoff

Control box cover for air blockoff

1 inch deep collar around return air opening on fan coil unit

1 inch drywall

Screw

Fan coil unit

5

61

5

1

2

1

3

5

6

6

1

4

6

5

4

Top side section Bottom side section

Table 8. Nominal return air door size

Size Door size (inches)

300, 400 18 x 56

600. 800 21 x 56

1000, 1200 25 x 56

NOTICE

Equipment Damage!

Failure to follow instructions below could result in

equipment damage. Ensure the horizontal run-out from

each riser is centered in the cabinet slot and at 90

degrees as it enters the cabinet prior to soldering the

risers.

Loading...

Loading...