SO-SVN048A-EN 31

Installation

Shut Down Power

1. Using lockout/tagout safety procedures, shut down the

chiller’s main power.

2. Open all starter and control panel disconnect switches and

secure them in the open position.

3. Confirm that the power is off to the control panel of the

chiller.

Vibration Mitigation - Line

Weights Kit for Oil Separator

Discharge Lines

The addition of an Adjustable Frequency Drive (AFD) on RTHD

chillers may result in vibration resonance at low frequencies on

the oil separator discharge line(s). Line weights are added to

mitigate this vibration.

RTHD ADF Line Weight Kit

Each line weight is comprised of two individual clamps.

Installation Instructions

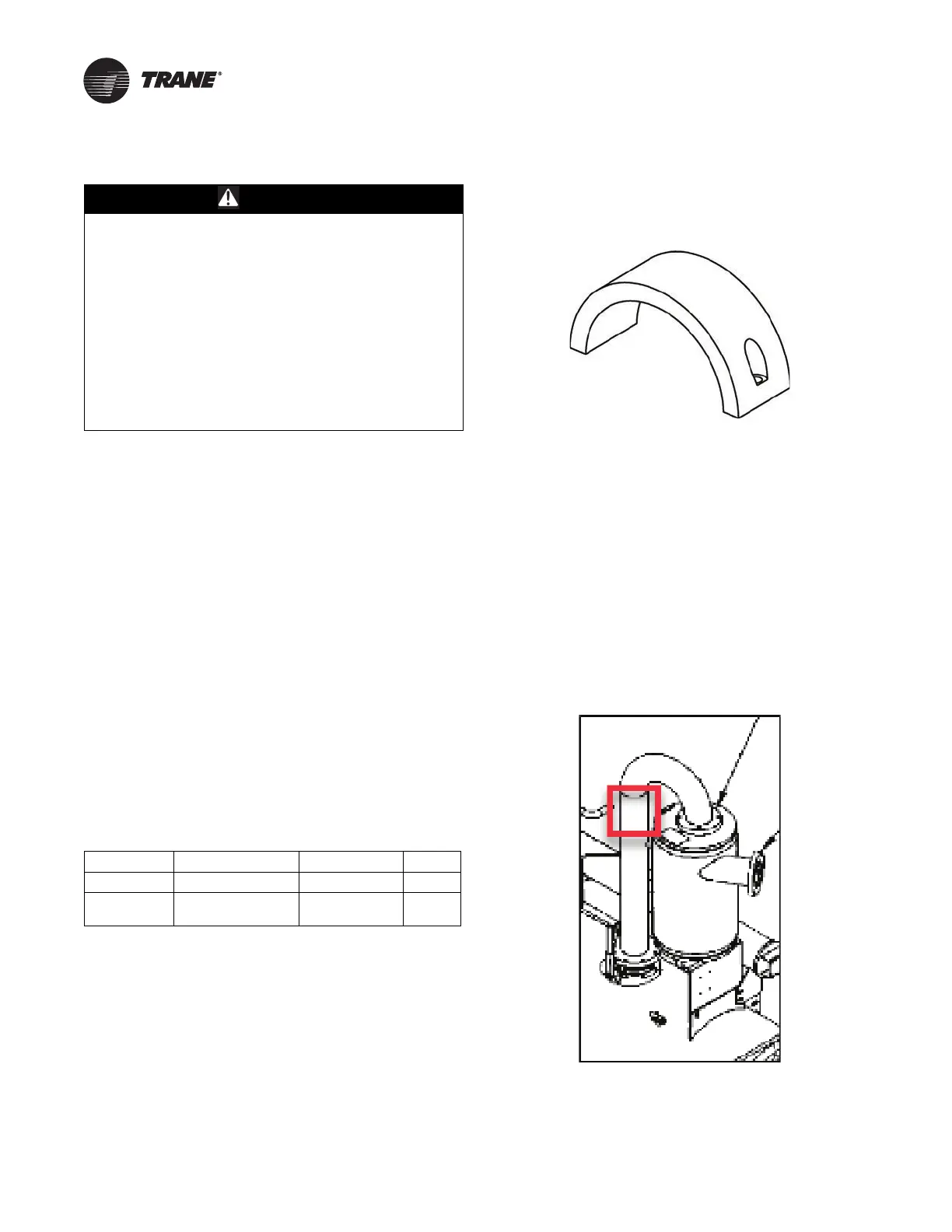

Chillers with B-Frame Compressor Size

• Number of oil separator discharge lines: 1

• Number of kits required: 1

Install 2 weights (4 clamps) on the single oil separator

discharge line as shown in figure below.

• Install on the candy cane line between the oil separator

and the condenser.

• Mount just below the weld or on any smooth surface in that

area.

WARNING

Hazardous Voltage w/Capacitors!

Failure to disconnect power and discharge capacitors

before servicing could result in death or serious injury.

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. For variable frequency drives

or other energy storing components provided by Trane

or others, refer to the appropriate manufacturer’s

literature for allowable waiting periods for discharge of

capacitors. Verify with a CAT III or IV voltmeter rated per

NFPA 70E that all capacitors have discharged.

Table 7. Line weight kit 017500010100

Component Mnuemonic Number Decsription Quantity

Clamp CMP01430 Clamp, Line Weight 4

Screw SCR02687

M6 x 30MM, SCH

CAP

4

Figure 27. Individual clamp (two required for each line

weight)

Figure 28. Line weight installation location – B-frame

compressors

Loading...

Loading...