6-1

CHAPTER 6

Troubleshooting

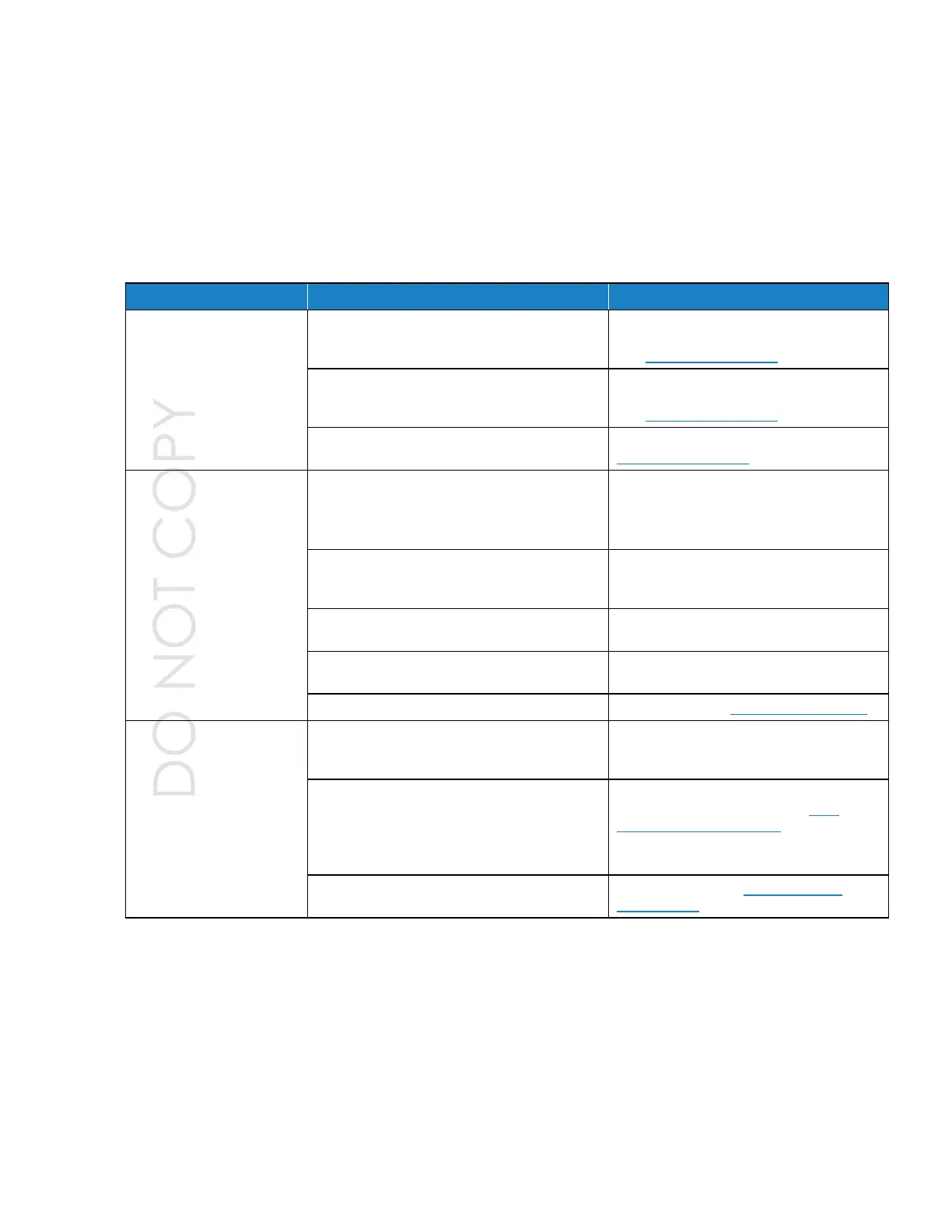

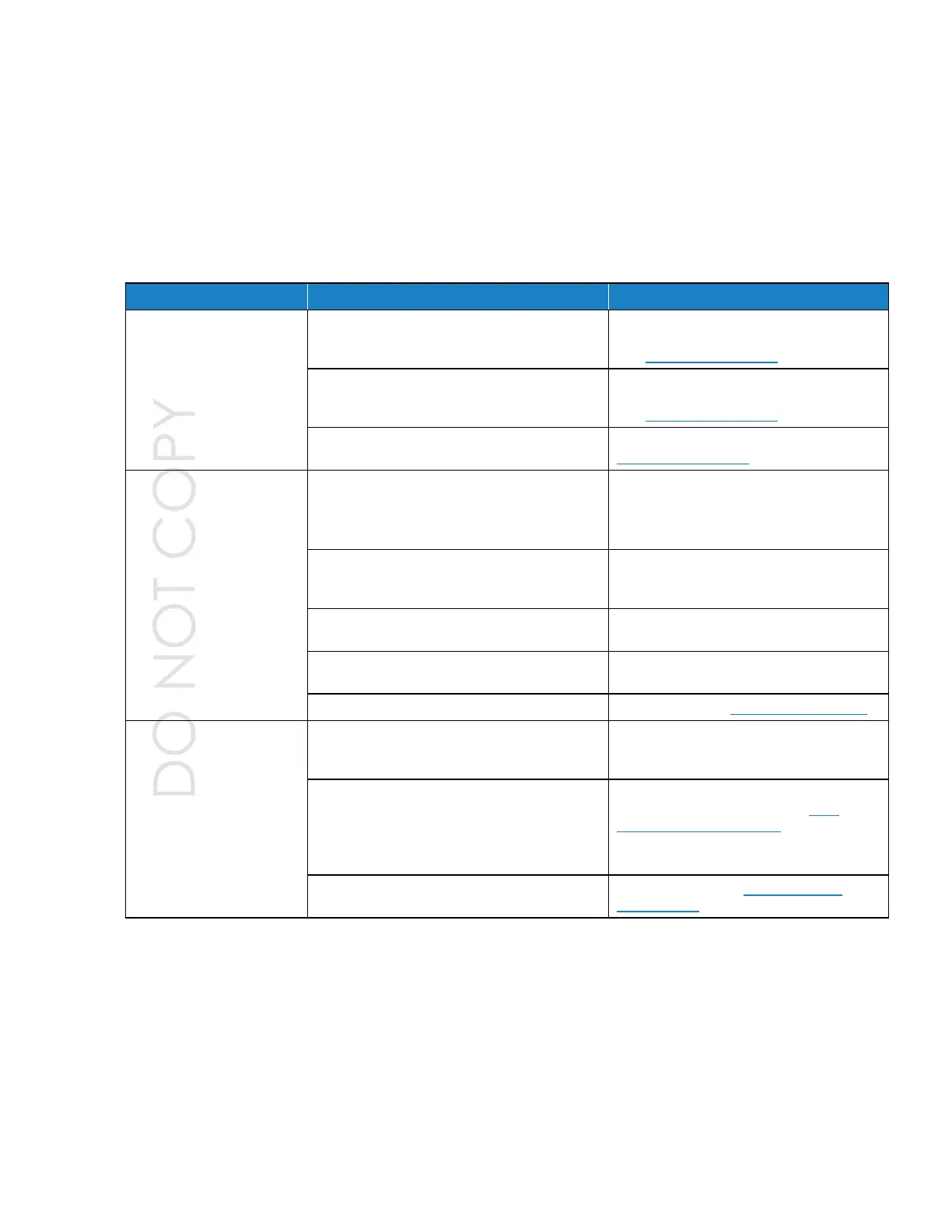

Display jittery or not

working (Model 9303)

Open unit and adjust potentiometer on

main board to modify display contrast.

See Display Replacement.

Inspect display cable for cuts or exposed

wires. Replace with new display module.

See Display Replacement.

Replace with new display module. See

Display Replacement.

Instrument does not meet

zero count specification

(<1 particle/5 min)

HEPA filter is not connected properly and

room air is leaking into the HEPA filter

assembly.

Check if the HEPA filter has been tightly

connected to the inlet.

Check if rubber O-ring (black) on the inlet

is in place.

Residual particles from previous samples are

shedding off internal parts and into the optics.

Purge instrument by running the

instrument for 10 to 15 minutes before

attempting zero count test.

The filter assembly or inlet is dirty or

contaminated with particles.

Clean the HEPA filter fitting or run an

extended test to clean out particles.

A leak has developed in the aerosol flow path

(Model 9303).

Tighten all tubing connections

Internal optics have become dirty.

Clean optics. See Optics Block Cleaning.

Pump not working

(Model 9303)

Use flowmeter to measure flow rate

(factory default 2.83 L/min). Redo flow

calibration if needed.

Check voltage on main board J3

supplying power to pump. See Main

Board Removal and Install step 3 for

position of J3. 6 V DC.

Check the crimp on the pump connector.

Replace pump. See Pump and Filter

Replacement.

Loading...

Loading...