40

Group 21 Short block

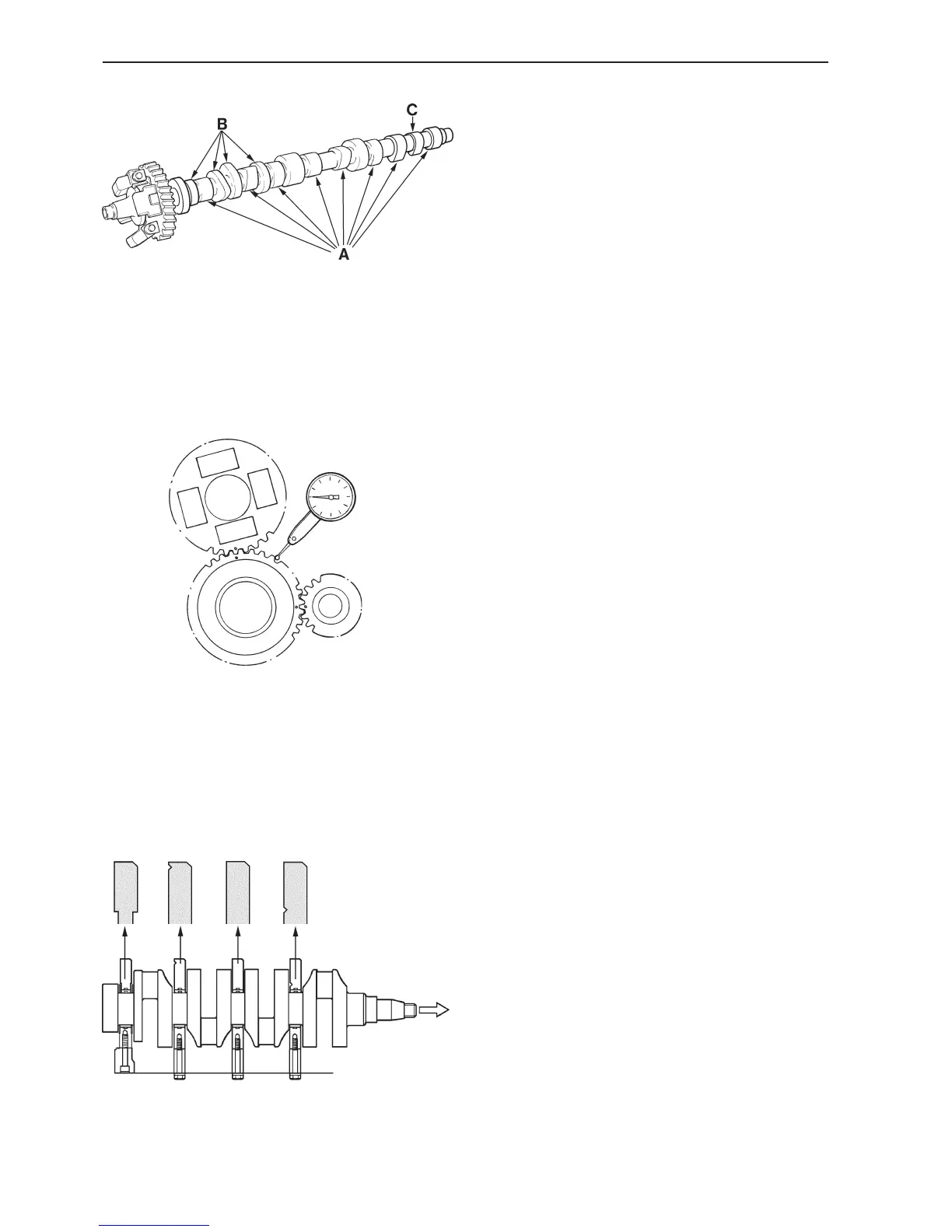

Measuring the camshaft

Cam height (inlet and exhaust), “A” 33.7 mm

Cam height “B” (for injection pump) 41.8 mm

Cam height “C” (for feed pump) 30.0 mm

Change the camshaft if the wear limits have been ex-

ceeded.

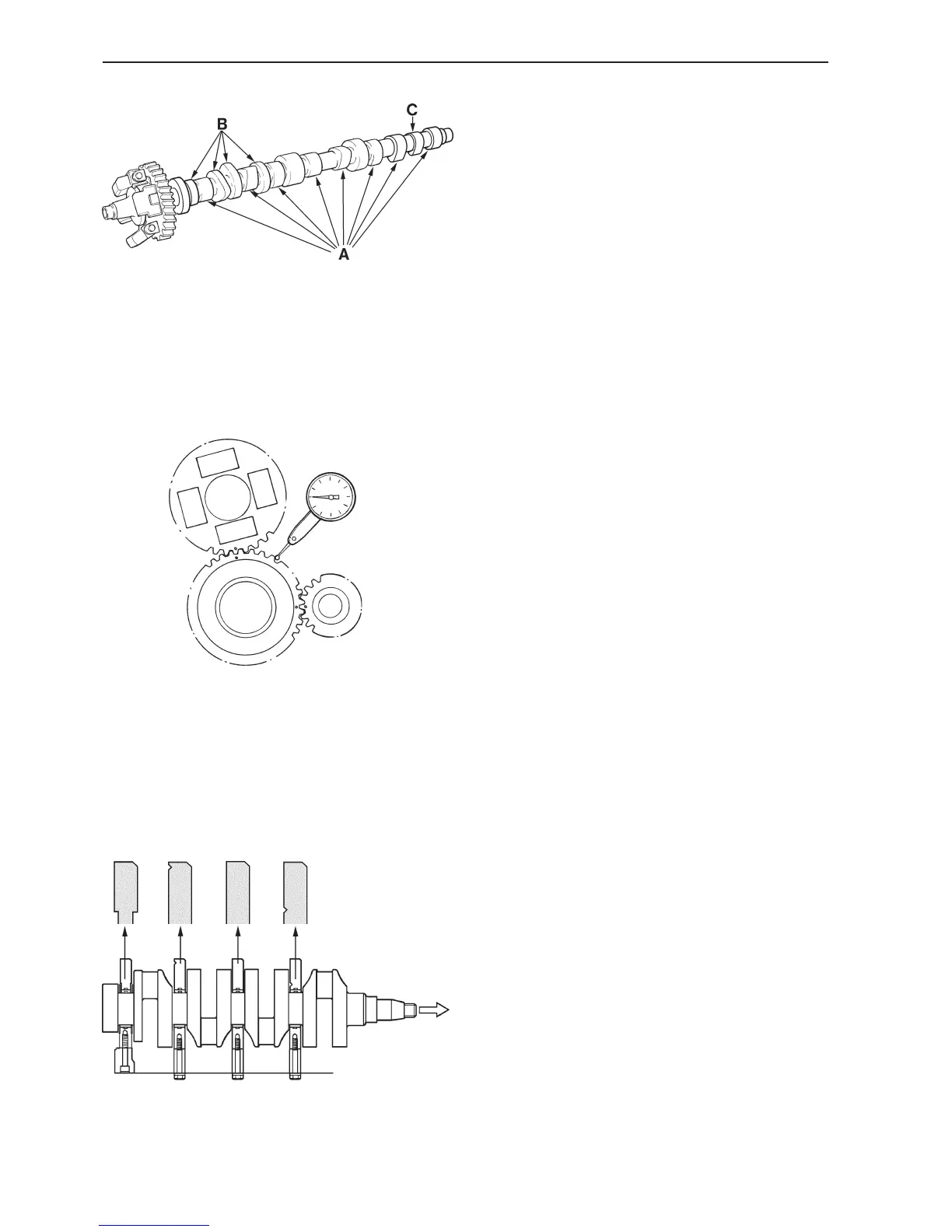

Inspection of timing gears

Special tools: 999 9683

Clean the gears and other parts of the timing system

and check them carefully. Replace gears that are bad-

ly worn or damaged.

Check the backlash with feeler gauges or a dial gauge,

special tool 999 9683.

Max. permitted backlash: 0.25 mm. If the backlash

exceeds the permitted value, then all gears in the tim-

ing system must be replaced.

Installing the crankshaft

Special tools: 998 9876, 999 9696

1. Check the cleanliness of the crankshaft drillings

and bearing surfaces, engine block and bearing

caps. Check that the bearing shells and their beds

do not have any burrs or upsets.

2. Place the main bearing shell in position in the

bearingcap. The bearing shells have an oil groove

that should be placed in the upper bearing cap.

Check that the lubrication holes in the upper

bearing shells are centered on the oil ducts.

3. Oil the bearing and main bearing journal and

mount the bearing cap in its correct place. The

chamfered edge shall face forwards on all bearing

caps.

Loading...

Loading...