71

Group 26 Cooling system

Coolant losses

There are two types of coolant losses:

• Coolant losses during operation.

• Coolant losses after stopping a hot engine.

Coolant losses during operation can be due to a leak-

ing cooling system or air or combustion gases being

forced into the cooling system.

Checking the pressure valve in

the filler cap

Special tools: 999 6662

1. Drain some of the coolant and connect the pres-

sure testing device 99 6662 to a nipple or other

plugged hole in the cooling system.

2. Extend the drain hose from the filler pipe with a

hose which ends up in a water - filled vessel.

3. Increase the pressure and read the pressure

gauge when the valve opens (water bubbles into

the vessel with the drain hose). The valve should

open at 0.09 MPa.

4. Remove the test equipment. Install the plug and

fill the engine up with coolant.

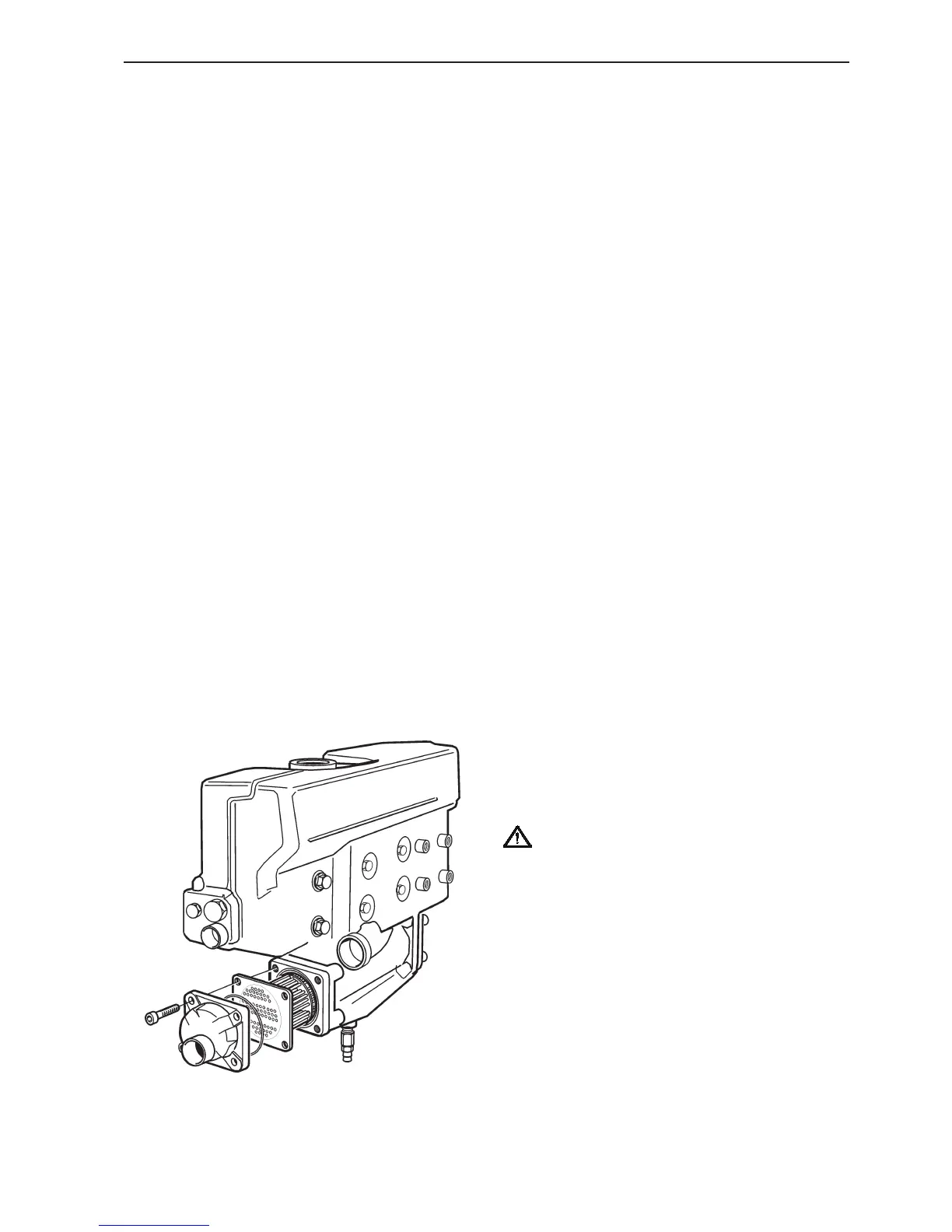

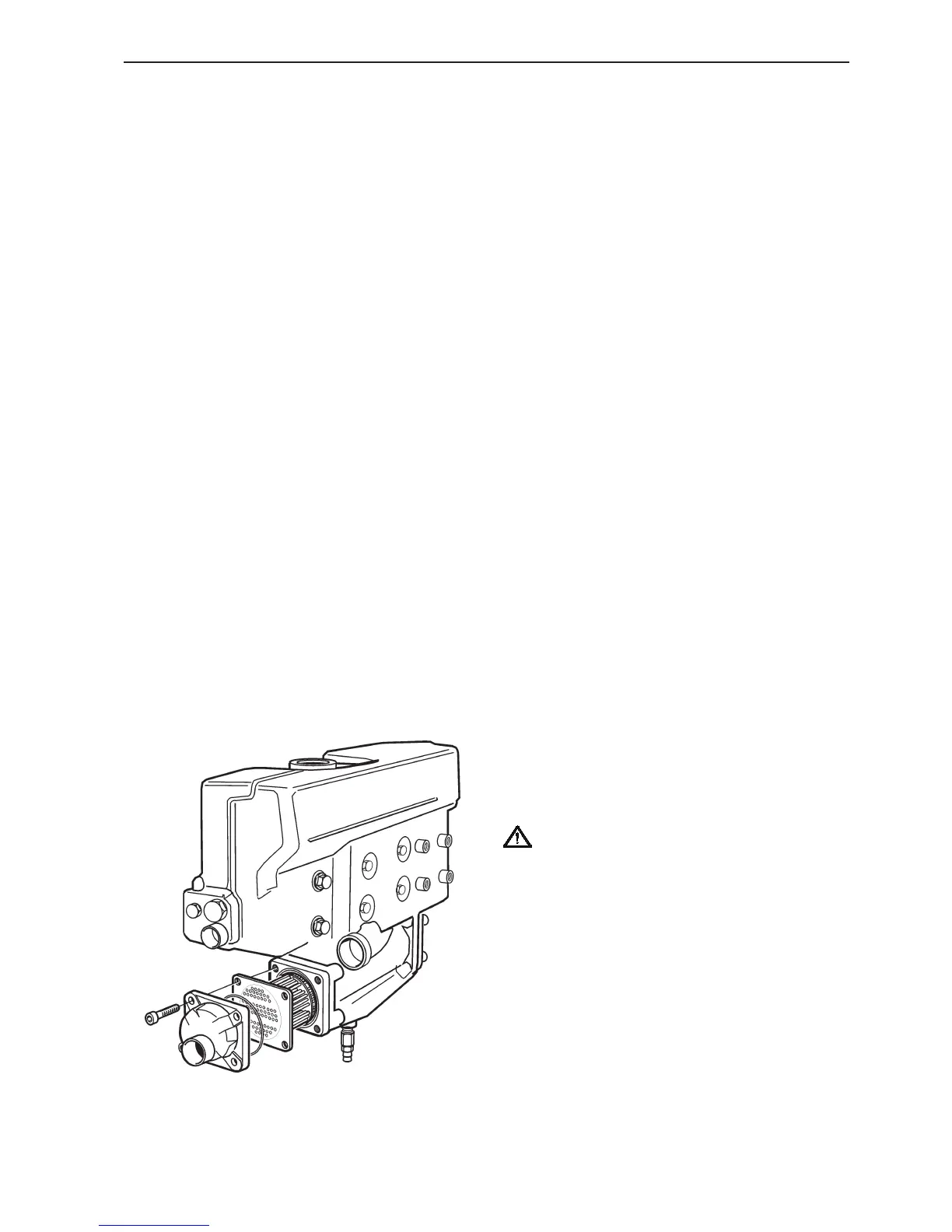

Cleaning heat exchanger

Clean the heat exchanger insert at any sign of block-

age (slowly increasing coolant temperature).

NOTE! First check/clean the seawater filter. Also

checkthe seawater pump impeller wheel and the sea-

water intake.

IMPORTANT! Close the sea cocks before work-

ing on the cooling system.

1. Drain the water from the seawater and freshwater

systems.

2. Disassemble the exhaust manifold together with

the heat exchanger.

3. Undo the screws and covers at the front and rear

of the heat exchanger. Pull out the insert.

4. Flush and clean the insert, both internally and ex-

ternally. Also clean the housing.

If there are loose deposits in the insert, cleaning can

be performed by passing a suitable steel rod through

the tubes in the opposite direction to the water flow.

NOTE! Check that the rod does not damage the

tubes.

Loading...

Loading...