46

Repair - MS2 reverse gear and upper gear housing, sailboat drive

Final assembly

107. Put a needle roller bearing (1) on the vertical

shaft.

Then put on the measured spacer washer (2), the

three domed small washers (3), the large domed

washer (4) and the lock washer (5).

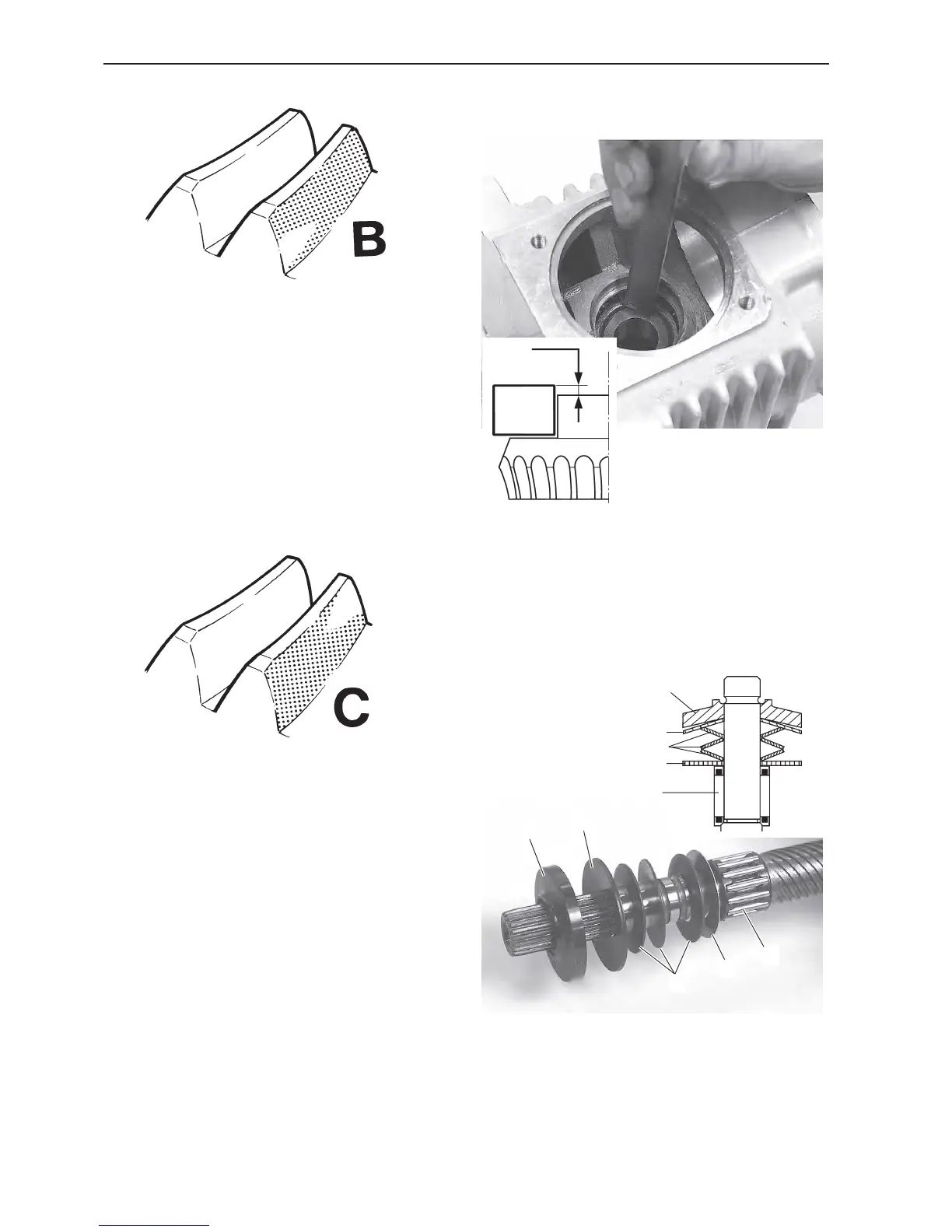

104. If the marking pattern resembles B, the shim

thickness in the input bearing housing should be re-

duced. If the gear flank clearance becomes too small,

the gear wheels must be disassembled.

Remove the shims from the gear wheels to the same

extent, and re-install the gear wheels.

Apply marking dye to the gears again, turn them round

and check the contact patches.

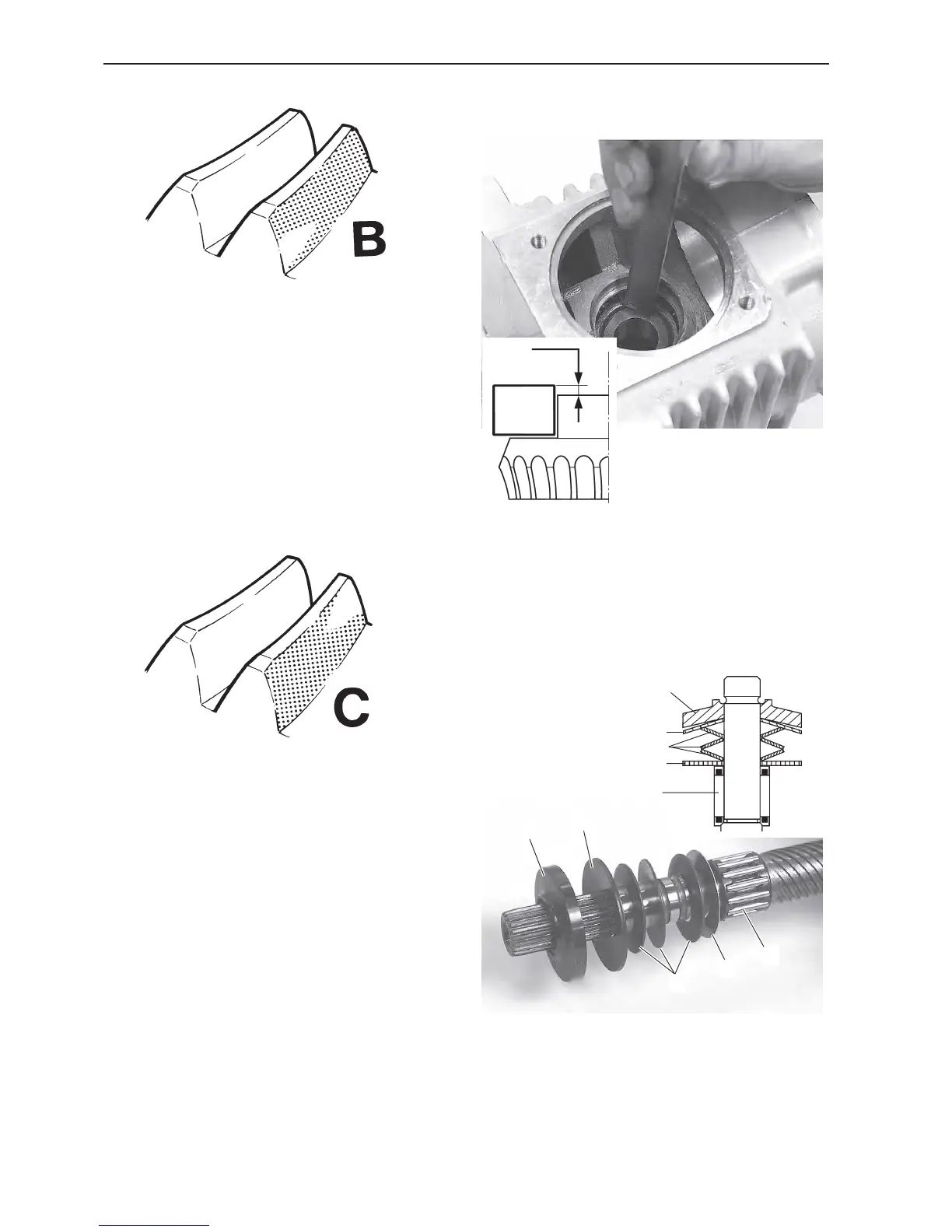

105. If the marking pattern is similar to C, move the

input gear housing and gear wheel in the opposite di-

rections to what was specified in item 104.

When the correct flank clearance and marking pattern

have been obtained, the input gear housing and upper

gear housing should be disassembled, and all marking

dye washed off.

NOTE! Keep the reverse gear upside down when the

lower gear wheel is washed clean, to prevent the dye

from finding its way into the bearing.

106. Measure distance (A) between the bearing and

gear wheel hub. This distance should be between 3.4

and 3.8 mm (0.13 and 0.15").

If the distance is 4.10 mm (0.161"), for example, a

spacer washer must be inserted.

If the distance exceeds 4.20 mm (0.165"), two spacer

washers must be inserted.

A

5

4

3

2

1

5

4

3

2

1

Loading...

Loading...