Do you have a question about the Wacker Neuson DPU Series and is the answer not in the manual?

| Model | DPU Series |

|---|---|

| Type | Reversible Plate Compactor |

| Frequency | 90 Hz |

| Travel Speed | Varies by model and surface conditions |

| Compaction Performance | Varies by model |

Outlines the manufacturer's commitment to safety, proper machine use, and prohibition of structural changes.

Safety precautions specific to vibratory plate operation, including external influences and operational safety.

Key safety measures for operating machines remotely, focusing on signal transmission and operator distance.

Identifies and illustrates the various external components of the vibratory plate.

Details the location and function of controls on the machine's center pole.

Identifies the parts and controls of the infrared remote control unit.

Explains the operation of remote control buttons, joysticks, and indicator lamps.

Covers essential pre-operation checks, including opening hoods and performing detailed inspections.

Important operational advice, safety warnings, and guidance for specific conditions like sloped surfaces.

Detailed steps for activating the machine, including powering on and entering activation PINs.

Instructions for starting and operating the machine using the physical center pole controls.

Guidance on starting and operating the machine remotely using the infrared control unit.

Explains how to operate the machine using the control handle, including speed and direction selection.

Details on moving, stopping, and controlling the machine remotely, including safety features.

Describes the machine protection system and its operational responses to prevent damage.

Procedures for safely shutting down and preparing the machine for storage or transport.

Instructions on how to use the emergency shutdown switch for immediate and safe machine deactivation.

Steps for charging the remote control's rechargeable battery using the provided charging cable.

How to access and use the diagnostic menu to view error memory and machine status.

Scheduled maintenance tasks performed at specific operating hour intervals.

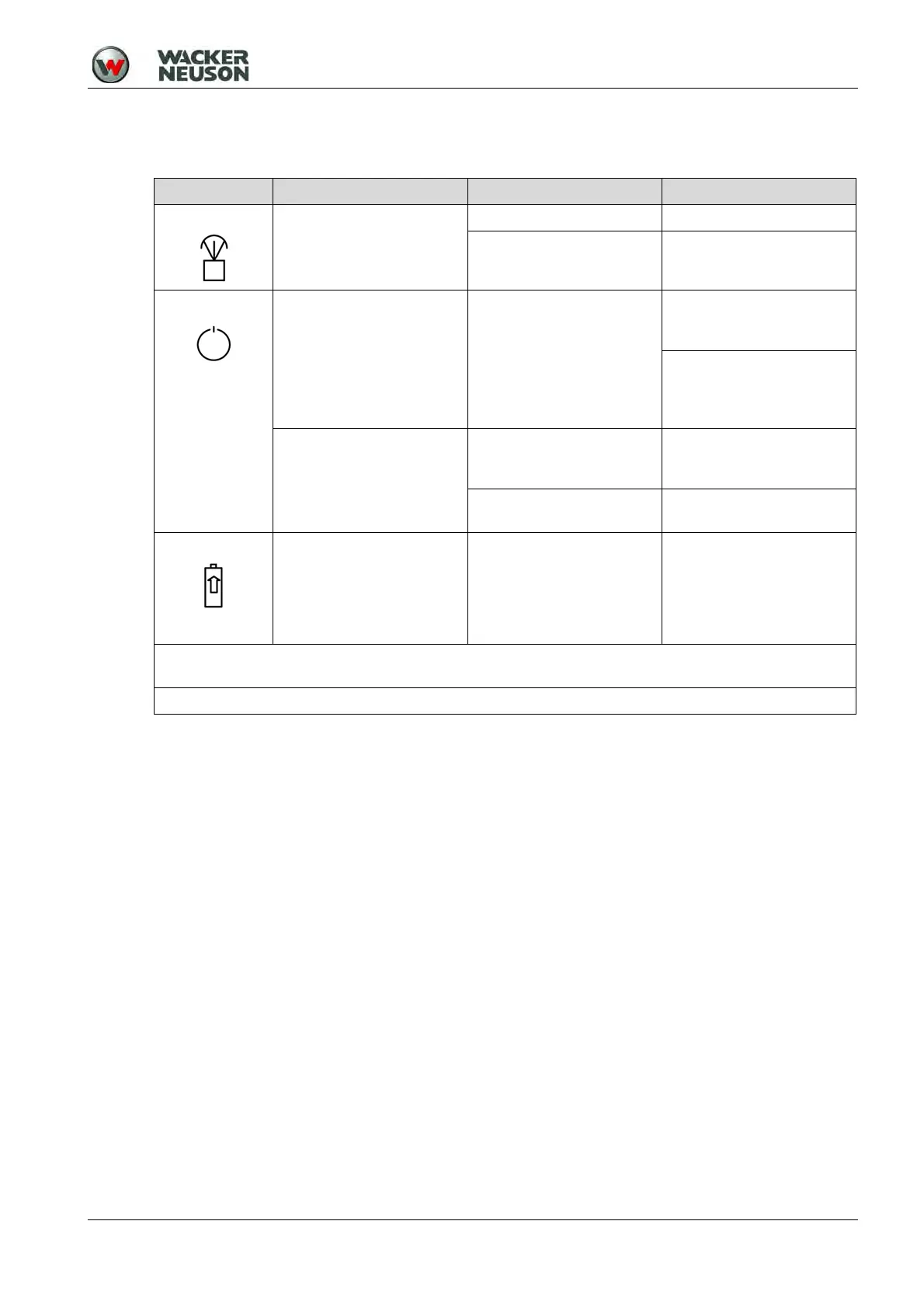

Identifies common machine faults, their potential causes, and recommended corrective actions.

Lists problems related to receiving units and provides solutions for remote control operation.

Details issues with the remote control, including LED indicators and battery problems, with remedies.

Covers faults indicated by the machine's display and control lamps, with corresponding solutions.

Step-by-step instructions for safely jump-starting the machine using a donor starter battery.