Rammer Repair Ramming System

wc_tx001547gb.fm 103

5.5 Inspecting the Spring System

See Graphic: wc_gr001329rm

Over time, the constant compression and release of the spring

pressure can cause the springs to wear out. If the rammer feels to be

hitting with less force, it is possible that the springs are worn and

should be replaced.

A broken spring causes the rammer to jump erratically. This condition

is more noticeable on hard soils. Do not run the rammer if a broken

spring is suspected. Doing so may damage other rammer parts.

Replace both the top and the bottom spring sets even if only one set is

worn or damaged.

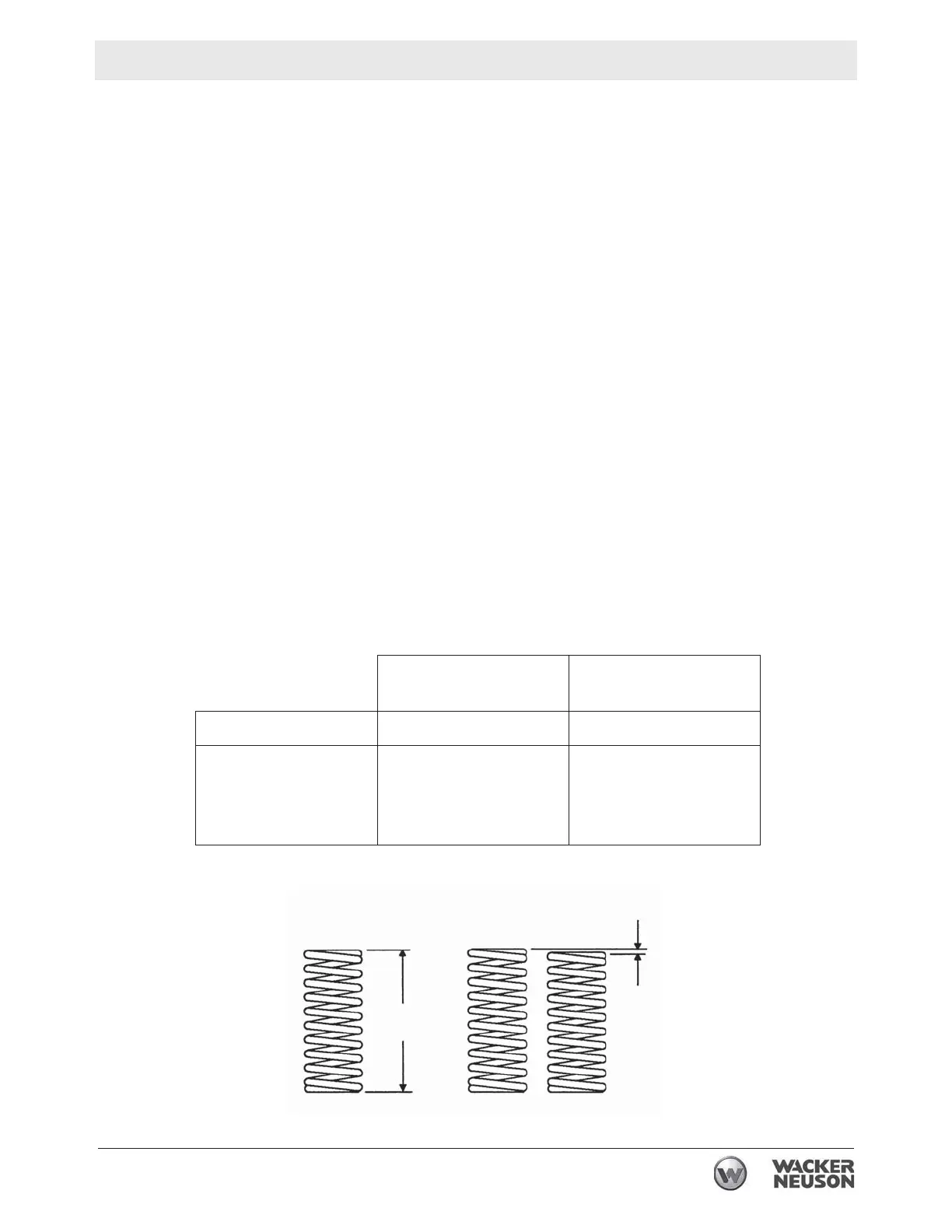

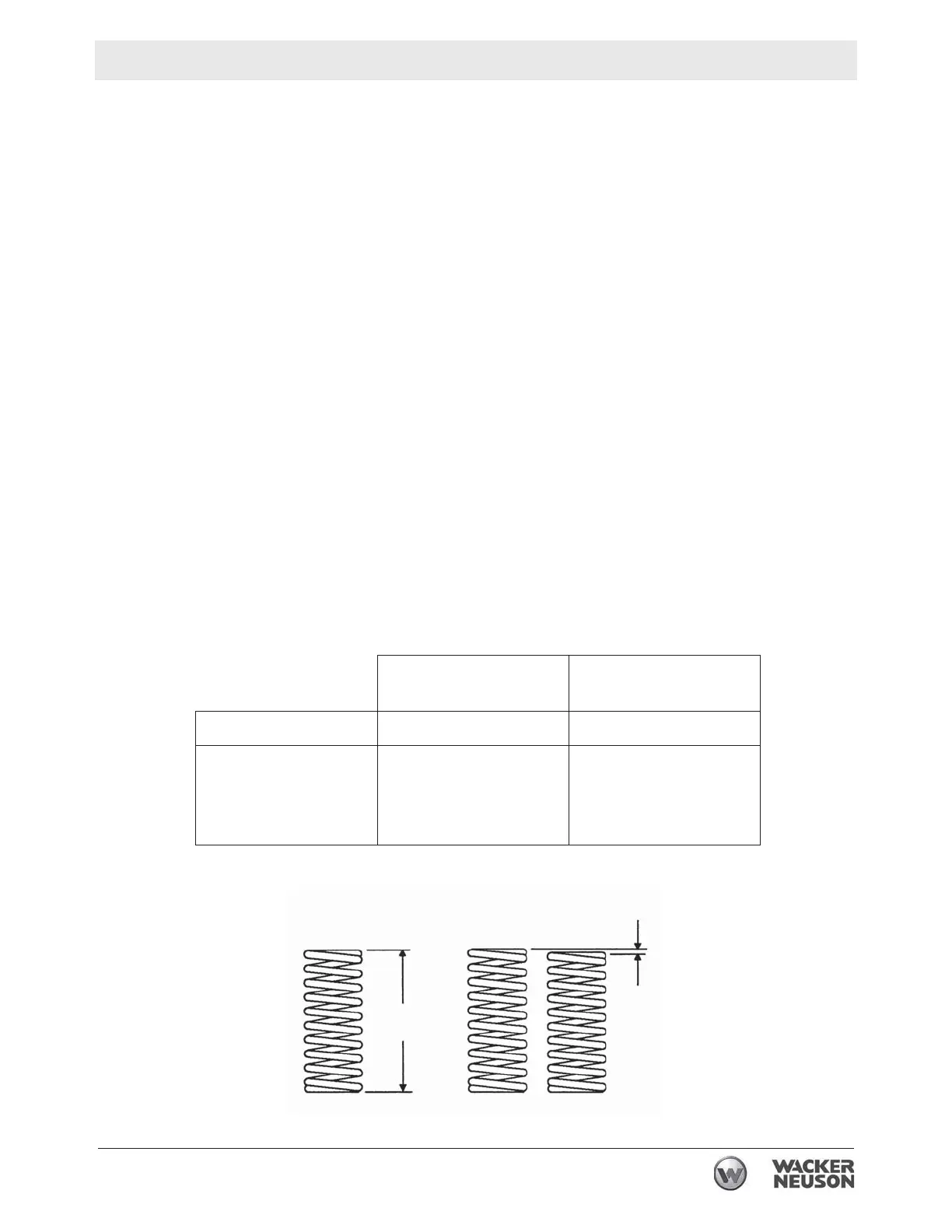

5.5.1 Remove the springs from the cylinder and check them for minimum

spring free height and maximum spring height difference per the table

below. Replace the springs if they do not meet the given specifications.

5.5.2 If a spring has broken, inspect the inside of the spring cylinder wall for

burrs, gouges, and cracks as follows:

• Slide the piston guide inside the cylinder. Check that the piston

guide moves freely but without excessive side play.

• Hone the cylinder to remove the ridges and the burrs that were

cut into the cylinder wall by the spring movement.

• Replace the cylinder if it is badly worn.

Minimum spring free

height (a)

Maximum spring

height difference (b)

BS 500, BS 50 194 mm (7 21/32 in.) 5 mm (3/16 in.)

BS 600, BS 60

BS 700, BS 70

BS 650, BS 65V

DS 720, DS 70

217 mm (8 9/16 in.) 5 mm (3/16 in.)

wc_

r001329rm

a

b

Loading...

Loading...