Rammer Repair Maintenance Schedules

wc_tx001545gb.fm 19

3 Maintenance Schedules

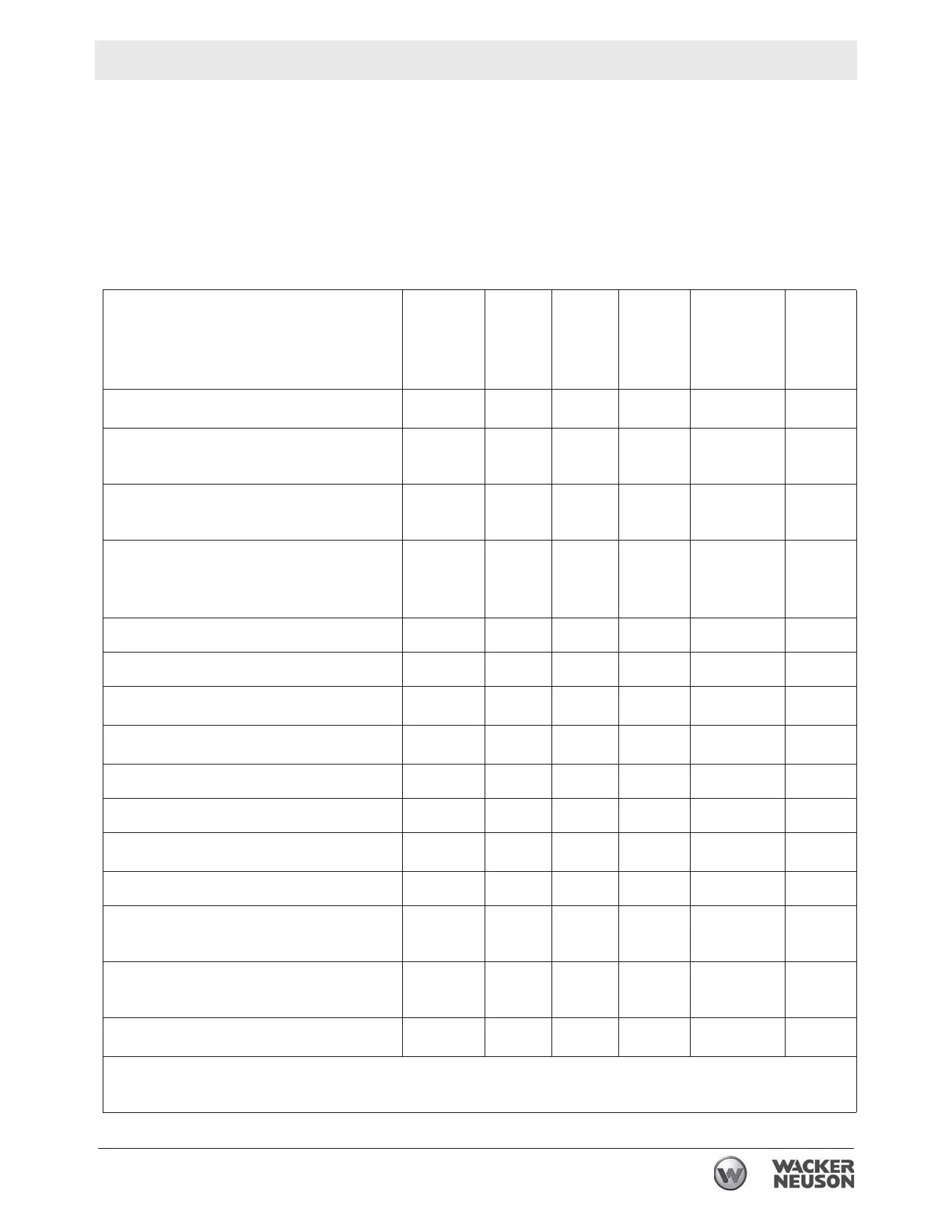

3.1 Periodic Maintenance Schedule (BS 50/60/70-2, BS 65)

The table below lists basic machine maintenance. Tasks designated

with check marks may be performed by the operator. Tasks

designated with square bullet points require special training and

equipment.

Daily

before

starting

After

first

5

hours

Every

week

or 25

hours

Every

month

or 100

hours

Every

3 months

or 300

hours

Every

Year

Check fuel level.

3

Check air filter indicator. Replace

as needed.

3

Check ramming system oil level in

sightglass.

3

Check fuel line and fittings for

cracks or leaks. Replace as

needed.

Tighten ramming shoe hardware.

Check engine cylinder screws.

Check external hardware.

33

Clean engine cooling fins.

3

Clean and check spark plug gap.

Replace spark plug.

Clean recoil starter.

3

Change ramming system oil.*

Clean engine muffler and exhaust

port.

Inspect lifting cable for wear,

damage, or abuse.

3

Inspect fuel filter.

3

* Change ramming system oil after first 50 hours of operation.

Note: If engine performance is poor, check, clean, and replace air filter elements as needed.

Loading...

Loading...