Rammer Repair Ramming System

wc_tx001547gb.fm 107

5.8 Ramming System Lubrication (BS 50/60/70, BS 65, DS 70)

Background

Lubricating oil is distributed throughout the ramming system by the

action of the rammer. Holes drilled in the piston carry oil from the

bottom of the rammer to the crankcase as the rammer operates. Oil in

the ramming system must be maintained at the correct level to ensure

the ramming system operates efficiently.

Checking the oil level

Perform the following procedure to check the ramming system oil

level.

Note: If the Rammer has been transported in the horizontal position or has

recently been used, upright it and allow it to stand in the upright position for

15 minutes before checking the oil level. This will allow the oil to settle and

provide a more accurate reading.

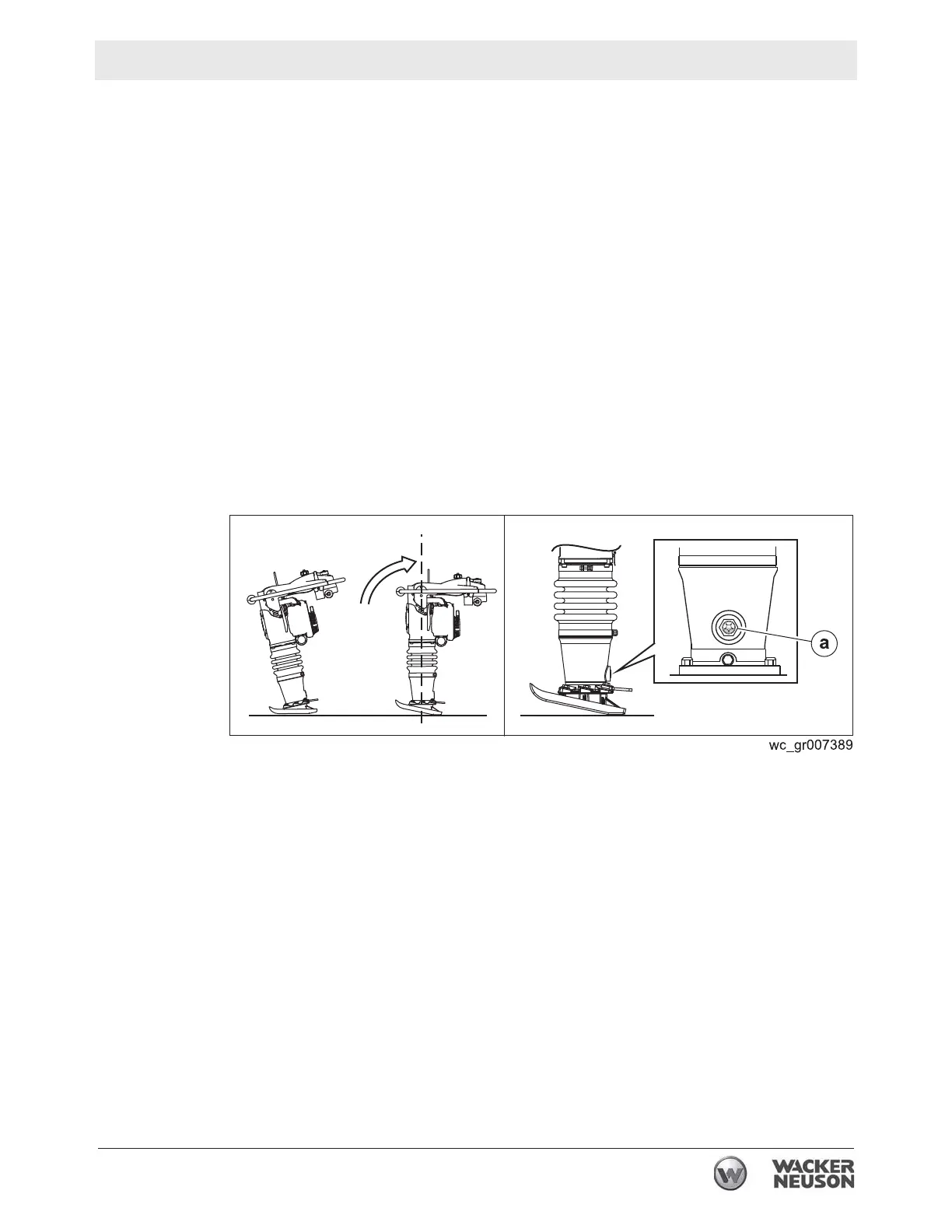

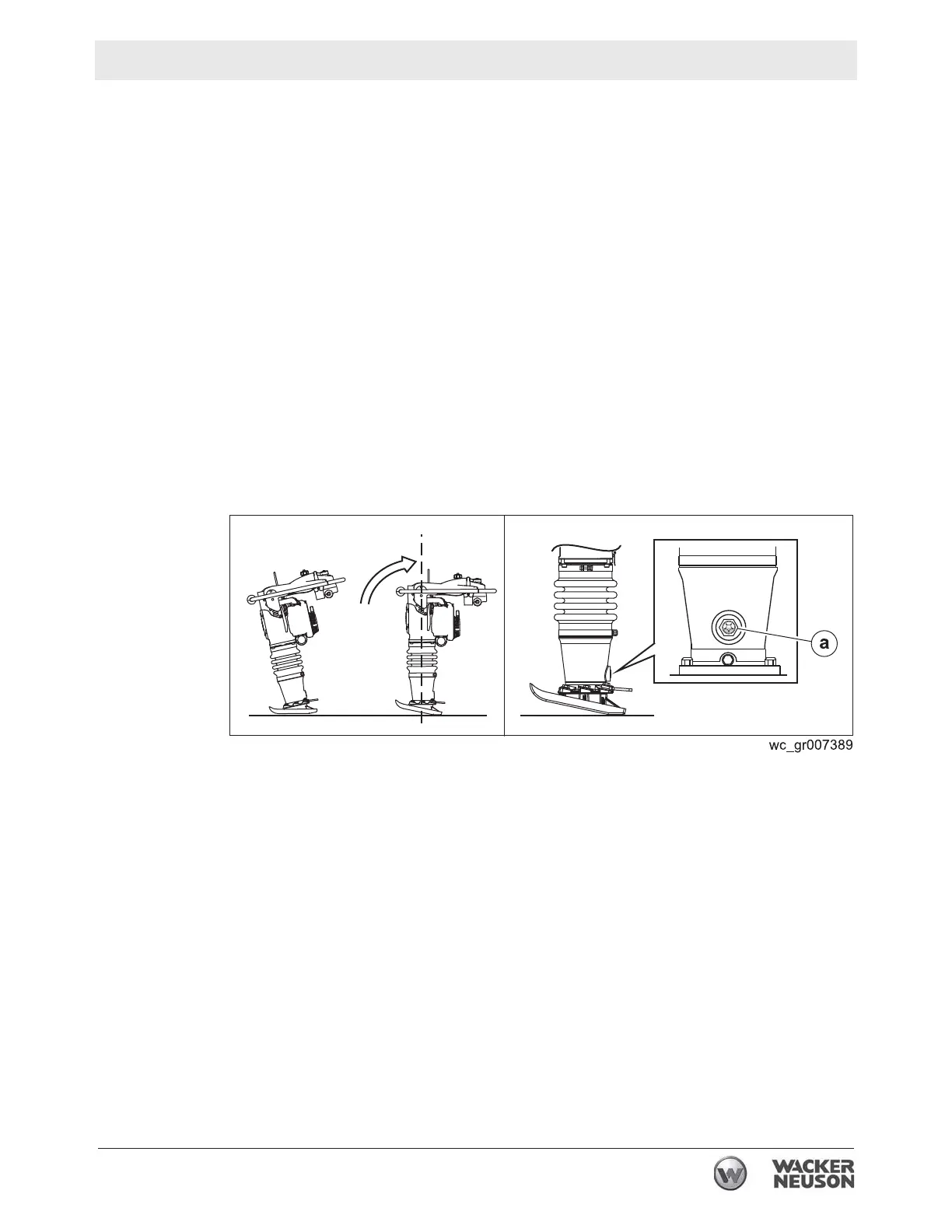

5.8.1 Tip the rammer so that it is perpendicular with the ground.

5.8.2 Check the oil through the sightglass

(a).

The correct oil level will fill 1/2 to 3/4 of the sightglass. Add more oil if

necessary.

Adding oil

Perform the following procedure to add oil to the ramming system.

NOTICE: Do not overfill the ramming system with oil. Excessively high

levels of oil can create a hydraulic lock in the ramming system. This

can result in erratic operation and cause damage to the engine clutch,

the ramming system, and the shoe.

5.8.3 Tip the Rammer forward to allow access to the sightglass. Secure the

Rammer in this position.

Loading...

Loading...