4A-1

50 HZ PORTABLE GENERATORS G2.1A/G2.1AE 4A

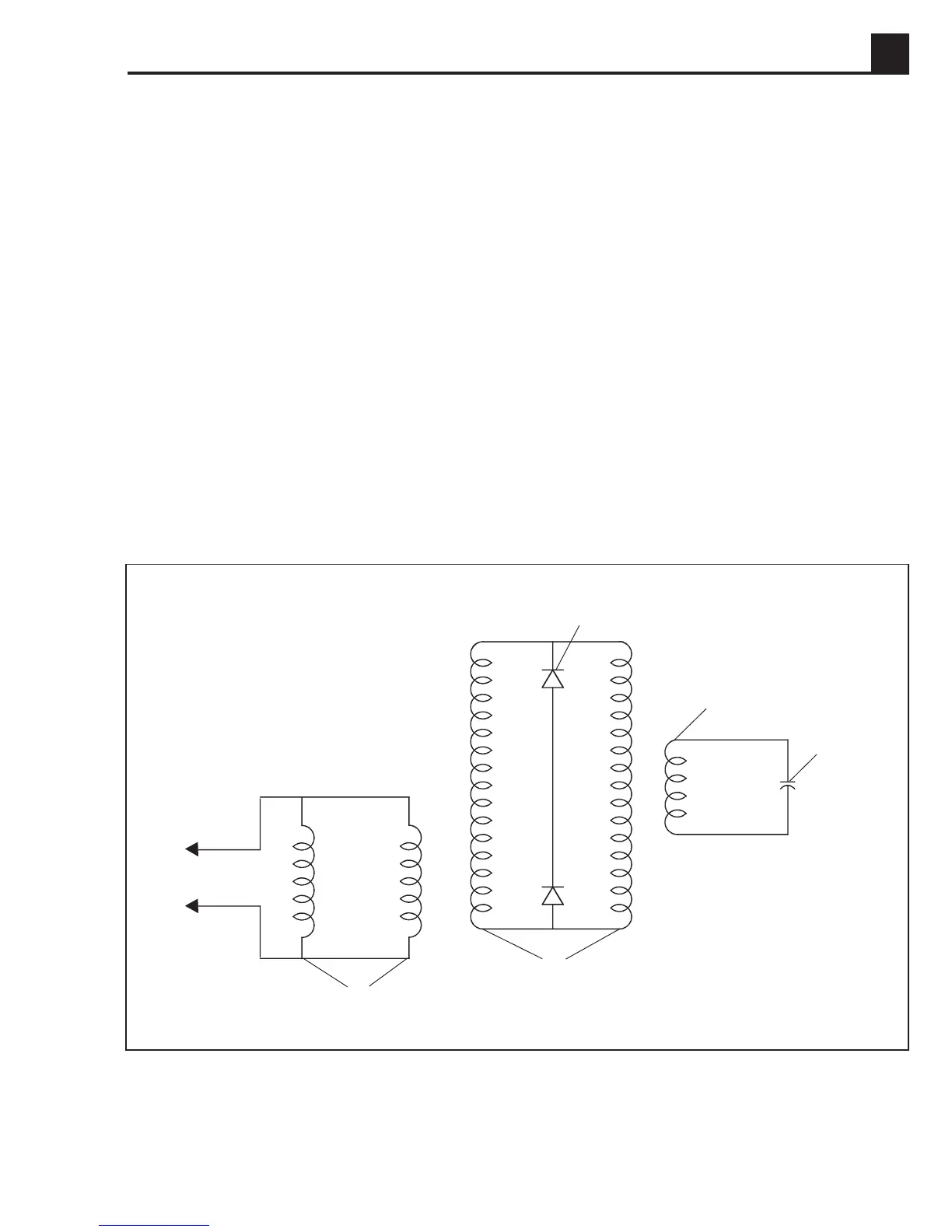

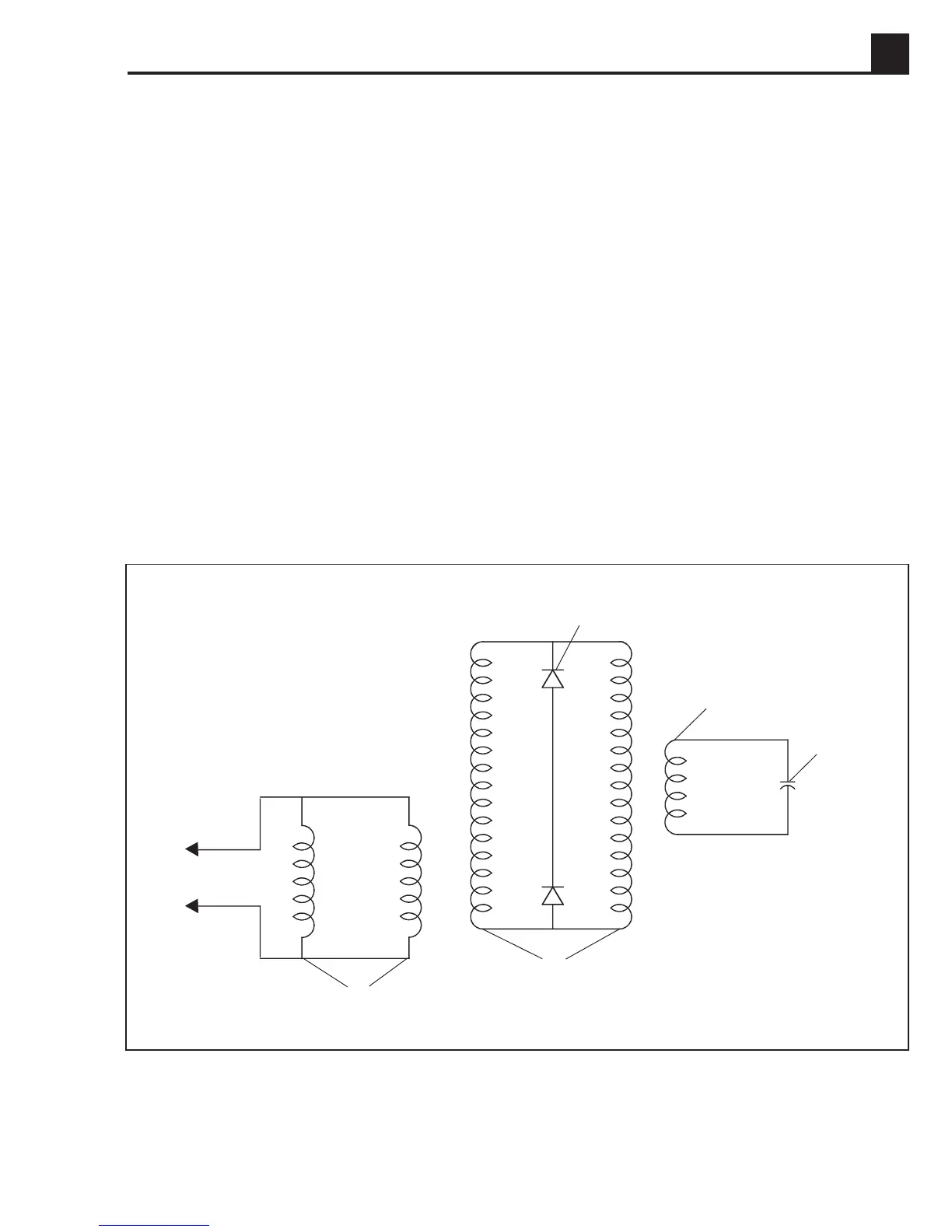

4.1 Theory of Operation – Capacitor Generators

Brushless Generator

This model generator uses a brushless design to generate

and regulate power. It consists of a rotor, stator, diodes,

and an auxiliary winding. The brushless generator also

contains a capacitor that is connected to the auxiliary

winding. Its purpose is to regulate the voltage in the main

windings and prevent a voltage drop when a load is

applied.

This generator is designed to operate with single phase

loads at or near a power factor of 1.0. The principle of

operation is schematically represented in Figure 4-1, and

a cross-sectional view in Figure 4-2. The auxiliary

winding (a), in conjunction with the capacitor, provide

excitation by inducing current in the rotor windings (b)

which is rectified by the diodes (c) to produce direct

current. The main stator winding (d) is designed for

parallel connection to give a voltage output with no

voltage adjustment possible.

Figure 4-1. Principle of Operation Schematic

1023SD44

d

Main Windings

b

Rotor Field

Windings

Capacitor

a

Auxiliary Winding

c

Diodes

(Rectifier)

Basic Generator Theory

Wacker air-cooled generators work on the principle of

electromagnetic induction i.e., the cutting of magnetic

lines of force by a coil of wire to produce an electric

voltage in the coil of wire.

The two main components of the generator, the rotor and

stator, are the key. The rotor acts as the magnet and the

stator acts as the coil of wire. As the rotor rotates, its

magnetic lines of force are cut by the coils of wire in the

stationary stator. The voltage induced in the windings of

the stator is tapped off and available at the receptacles.

Loading...

Loading...