4A-4

4A G2.1A/G2.1AE 50 HZ PORTABLE GENERATORS

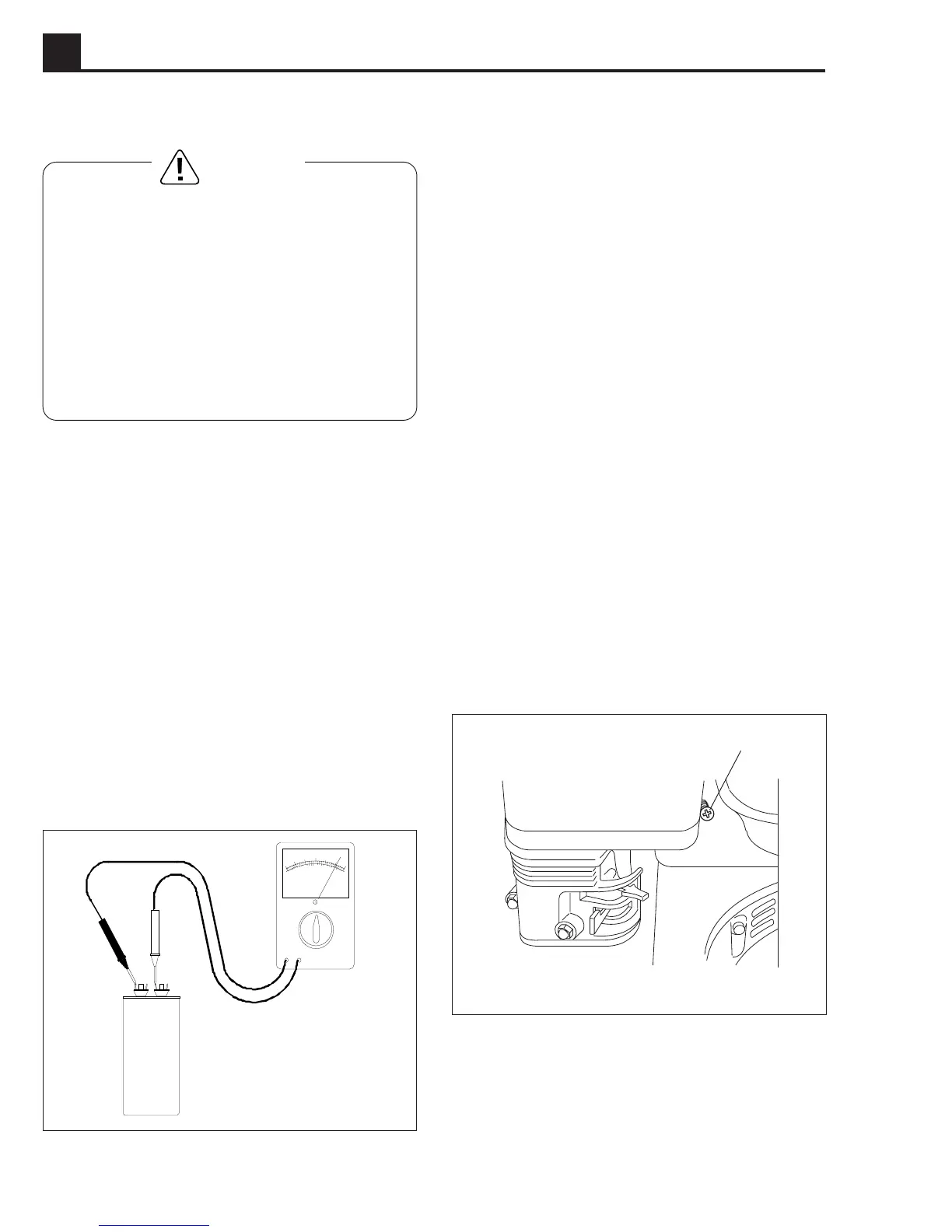

Figure 4-4. Testing Capacitor

4.8 Capacitors

Testing Capacitor

1. Discharge capacitor as described above, then

disconnect all wire leads from the terminals.

2. Check the capacitor charge and discharge readings

using an ohmmeter as described below or use a

capacitor checker. See Figure 4-4.

Set Ohmmeter on R x 10k scale.

Set meter leads on capacitor terminals. The meter

should deflect momentarily towards zero (fully

discharged) and then slowly climb up to infinity

(charging).

Reverse meter leads and repeat procedure. Results

should be the same.

3. If meter does not deflect torward zero, or deflects to

zero and remains there, the capacitor is open or

shorted and must be replaced.

ALWAYS handle or test capacitors with the engine

stopped. Extremely high voltage is present at the

capacitor terminals while the generator is in use.

Although the capacitors used in this generator are

designed to discharge when the engine is stopped,

it is still a good idea to discharge them manually

before handling. To discharge a capacitor, place a

conductor, such as a screwdriver with an insulated

handle, across the capacitor terminals. Be sure to

touch only the insulated handle. This will short out

across the terminals and discharge the capacitor.

WARNING

1007SD87

4.9 Engine Speed

All generators require a fixed engine speed to maintain

the correct voltage output. Engine speed is controlled by

a governor which automatically adjusts to varying loads

on the engine to maintain a constant speed of 3000 –

3100 rpm.

Testing Engine Speed

Measure the engine speed using a tachometer with no

load applied to the generator. The engine must be

running at 3100 ± 50 rpm. Voltage output is directly

related to engine speed. A slow engine will reduce

voltage. Refer to the Operator’s Manual for engine speed

adjustment.

The generator is designed to produce no output if

engine rpm falls 10% or more below the required

speed (approximately 2700 rpm).

Setting Engine Speed

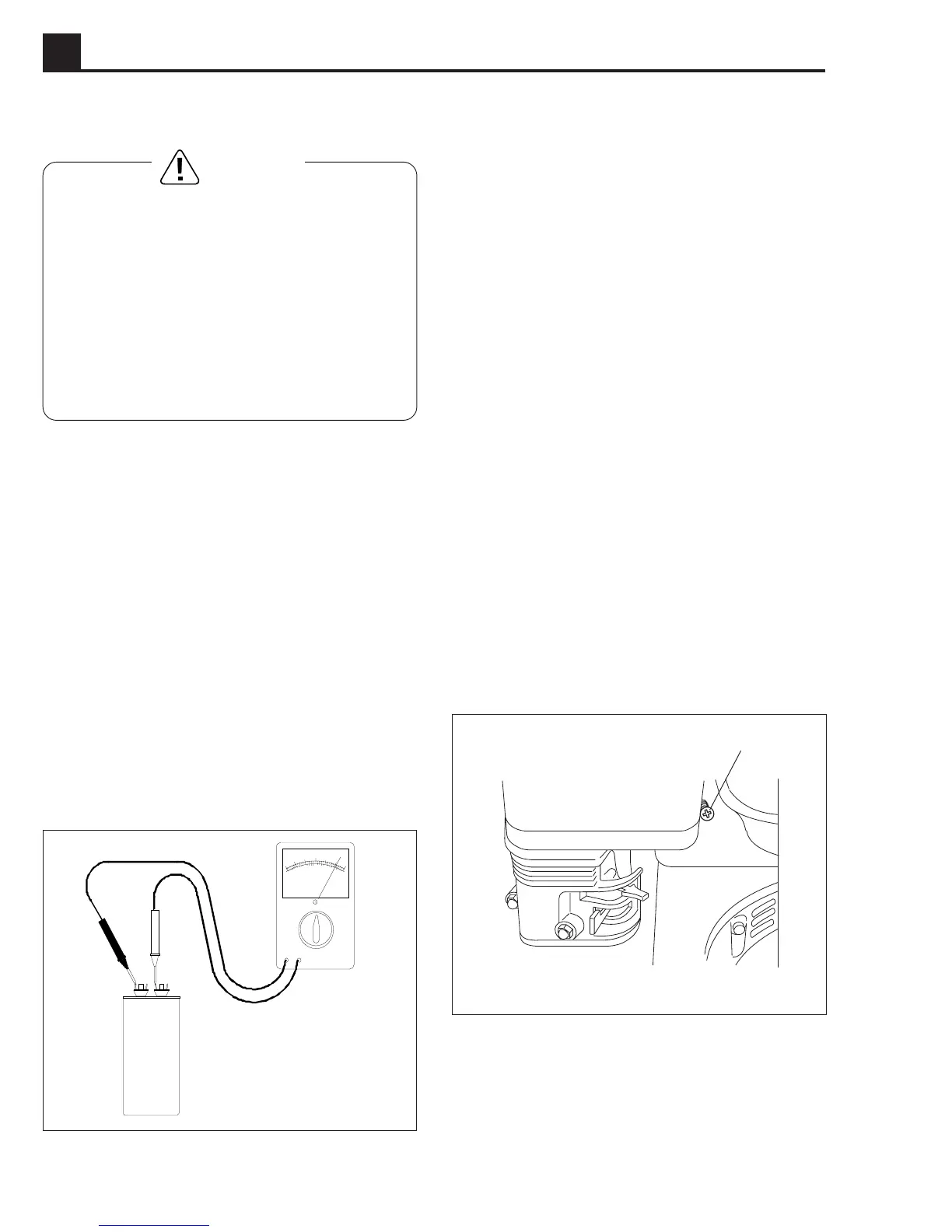

Setting the engine speed requires the adjustment to the

governor. See Figure 4-5.

To set the engine to the proper speed:

Turn the engine speed adjusting screw (a) in or out

to obtain a no-load speed of 3100 rpm.

CAUTION: Setting the engine speed too high or too low

may damage tools and other appliances attached to the

generator.

1001SD15

Figure 4-5. Engine Speed Adjusting Screw

a

Loading...

Loading...