4A-8

4A G2.1A/G2.1AE 50 HZ PORTABLE GENERATORS

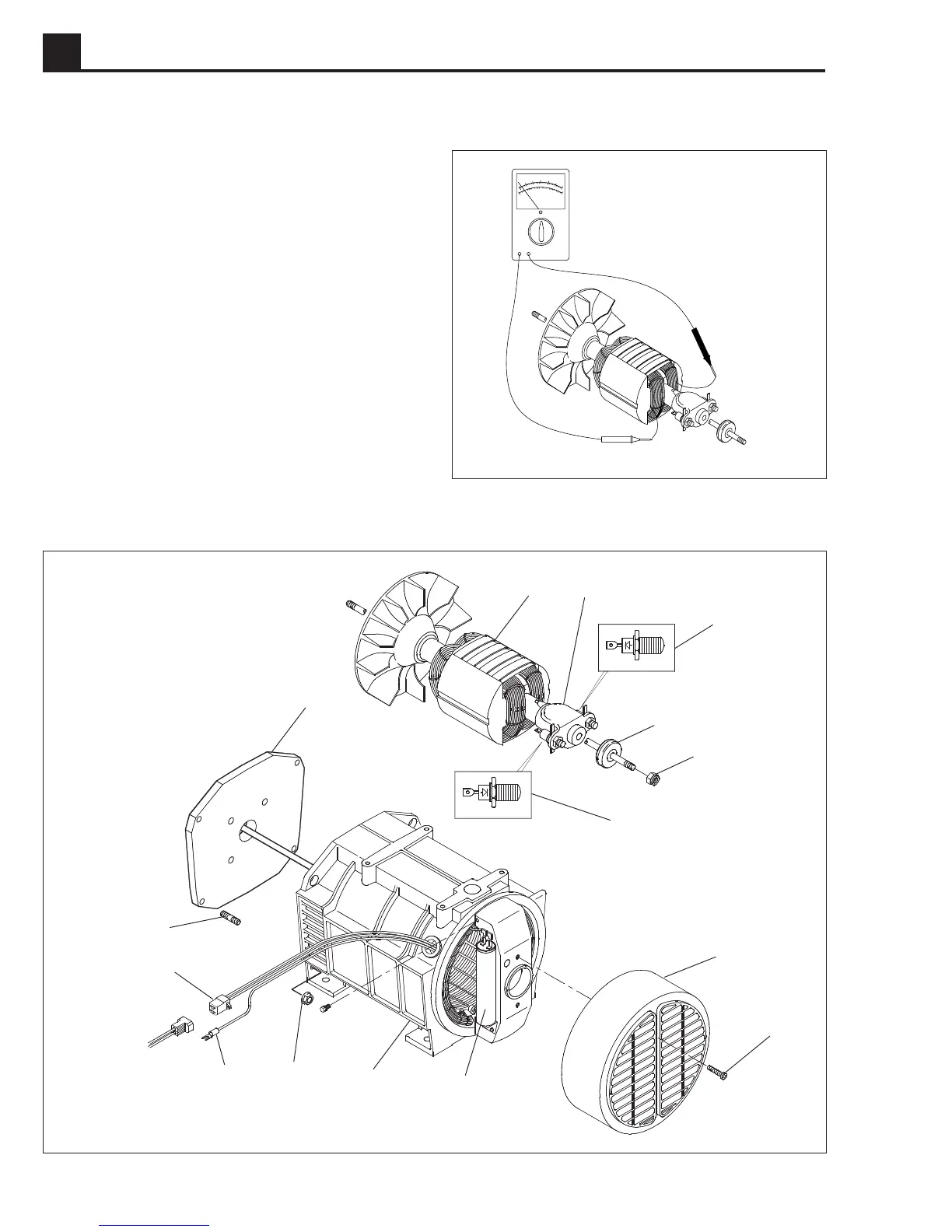

4.14 Rotor Winding Testing

Before testing rotor, visually inspect windings for dark

streaks which indicate a burned or shorted winding.

Rotate ball bearing by hand. Replace it if it is rough or

noisy.

To check rotor:

1. Remove end cover, locknut, stator and rotor from

generator. See Section 4.15

Generator Disassembly

.

2. Unsolder wires from diodes, being careful not to break

wires.

3. Measure rotor resistance as shown in Figure 4-9.

4. Record resistance values of both windings and com-

pare them with values listed in Table 4-1.

5. Check for grounded windings by holding one meter

lead to winding and other lead to metal frame on rotor.

Replace rotor if windings are open, shorted internally or

shorted to metal frame.

Figure 4-9. Rotor Winding Testing

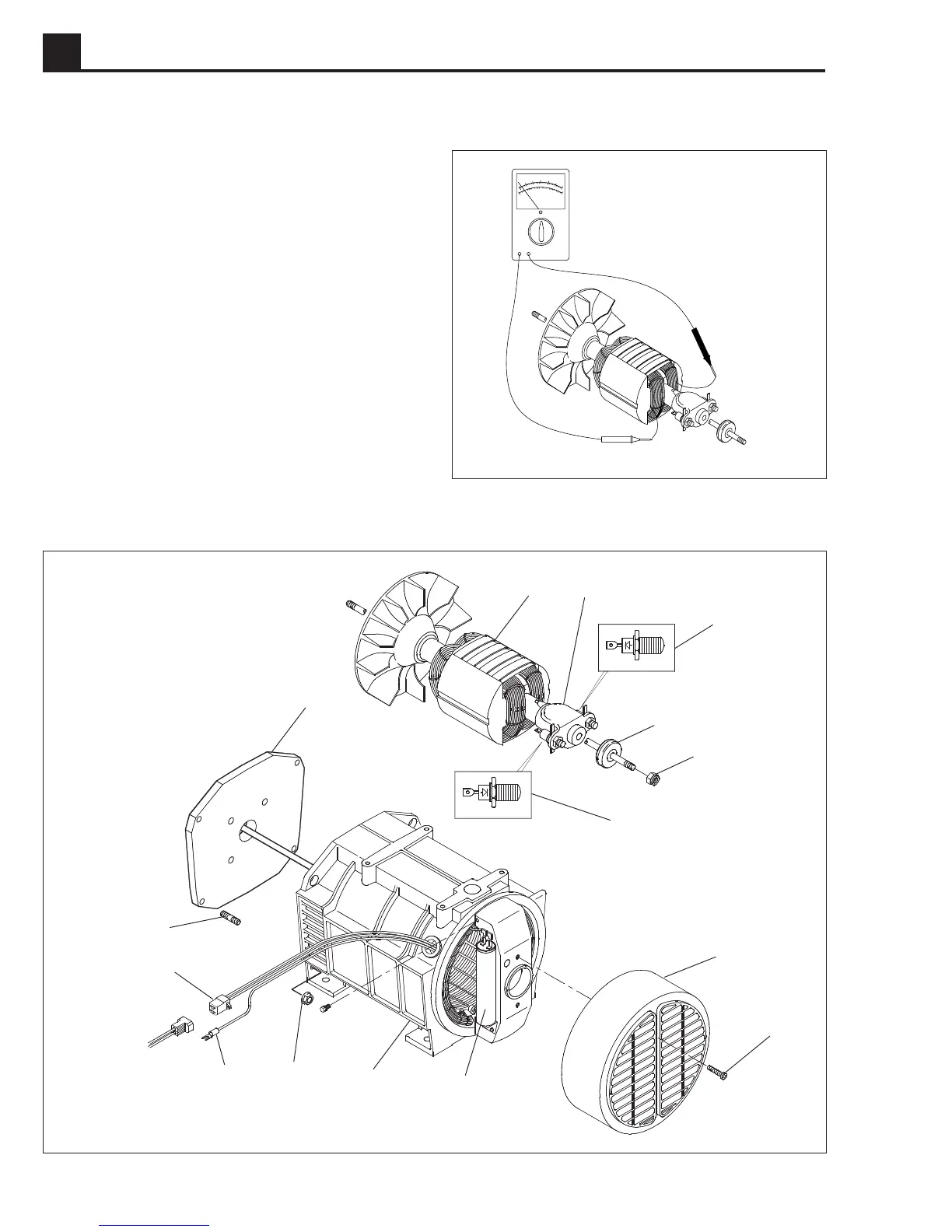

Figure 4-10. Brushless Generator

1023SD47

15

14

12

11

9

10

5

5

3

4

8

7

13 ft. lbs.

(17.5 Nm)

2

1

13

1024SD04

Loading...

Loading...