6D93G11

5-12

1

2

3

4

5

6

7

8

9

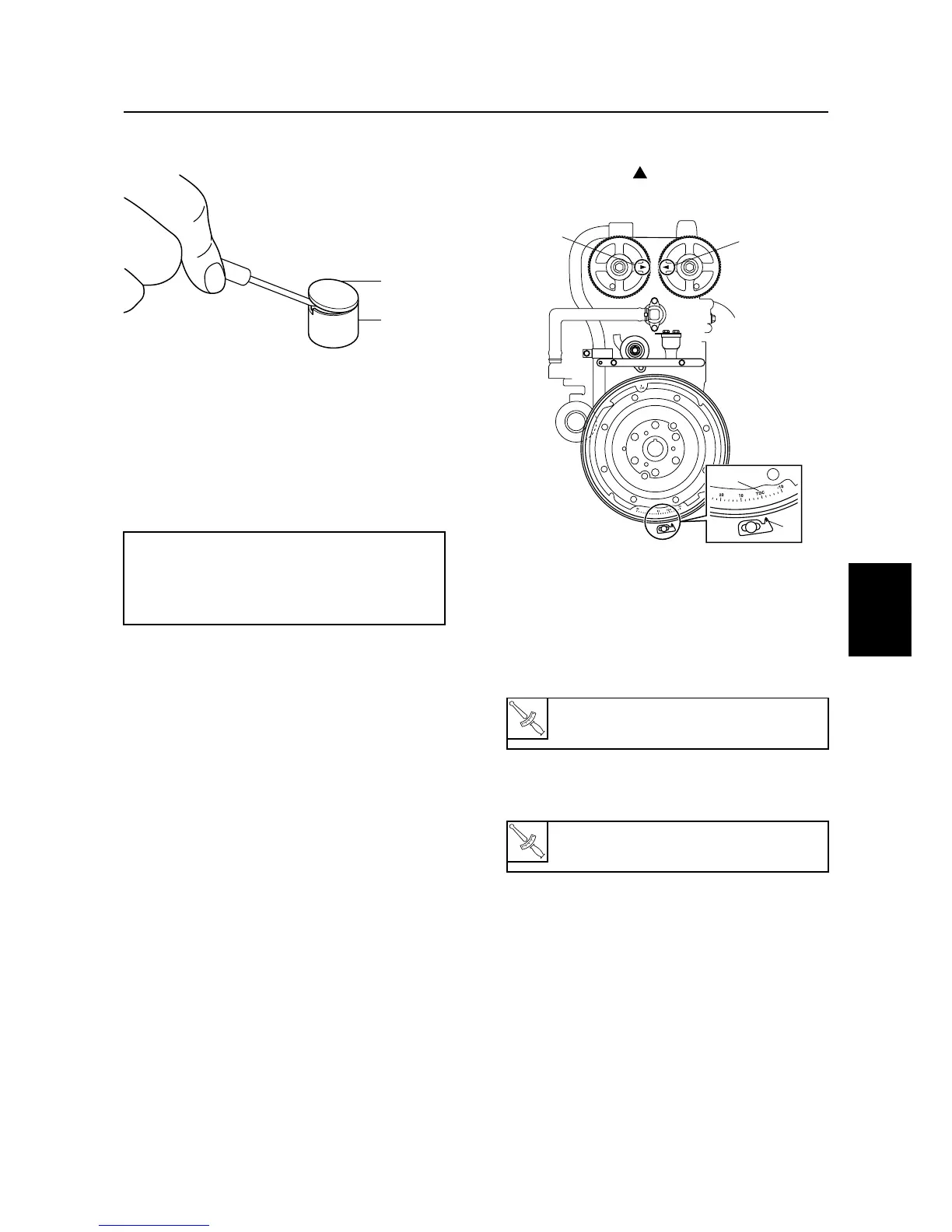

11. Remove the valve shim

C

from the valve

lifter

D

using a thin screwdriver.

12. Measure the valve shim thickness with a

micrometer, and then note the measure-

ment.

13. Select the necessary valve shim by cal-

culating its thickness with the following

formula.

Example:

If the “Removed valve shim thickness” is 2.10

mm, the “Measured valve clearance” is 0.30

mm and the “Specified valve clearance” is

0.20 mm, then the necessary valve shim

thickness = 2.10 + 0.30 – 0.20 = 2.20 mm

14. Install the necessary valve shim into the

valve lifter, and then install the valve lift-

ers into the cylinder head.

15. Install the camshafts, camshaft caps,

driven sprockets, and timing belt, and

then tighten the tensioner bolt.

16. Check the valve clearance. Adjust if nec-

essary.

17. Loosen the tensioner bolt, and then

remove the timing belt and driven sprock-

ets.

18. Install the cylinder head cover and driven

sprockets.

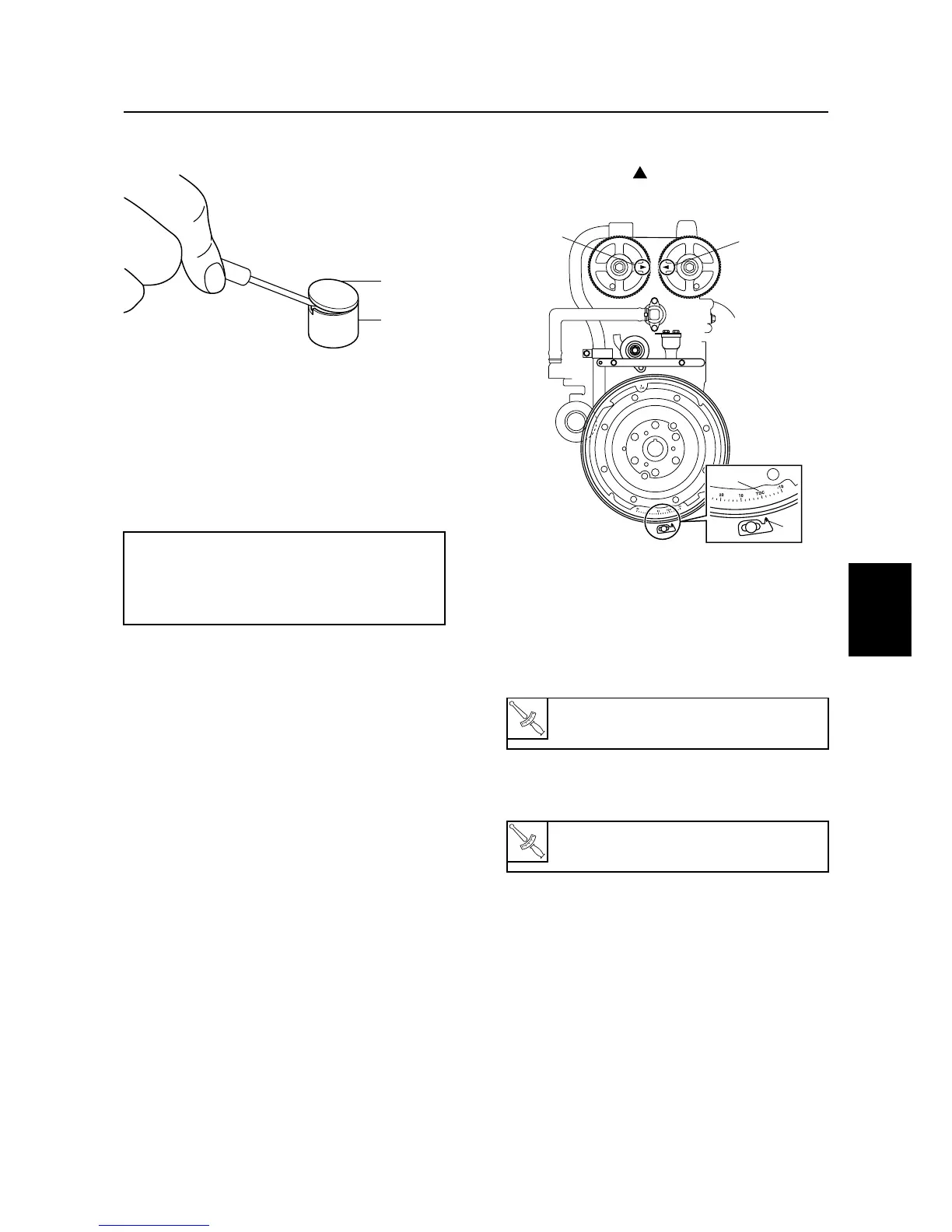

19. Check that the “TDC” mark

a

on the fly-

wheel magnet is aligned with the pointer

b

, and that “” marks

c

and

d

on the

driven sprockets are aligned.

20. Install the timing belt.

21. Install the spark plugs, and then connect

the spark plug wires, fuel hoses, and

blowby hose.

22. Install the spark plug wire cover, filter,

and flywheel magnet cover.

Necessary valve shim thickness =

Removed valve shim thickness +

Measured valve clearance – Specified

valve clearance

S6D85190

C

D

Loading...

Loading...