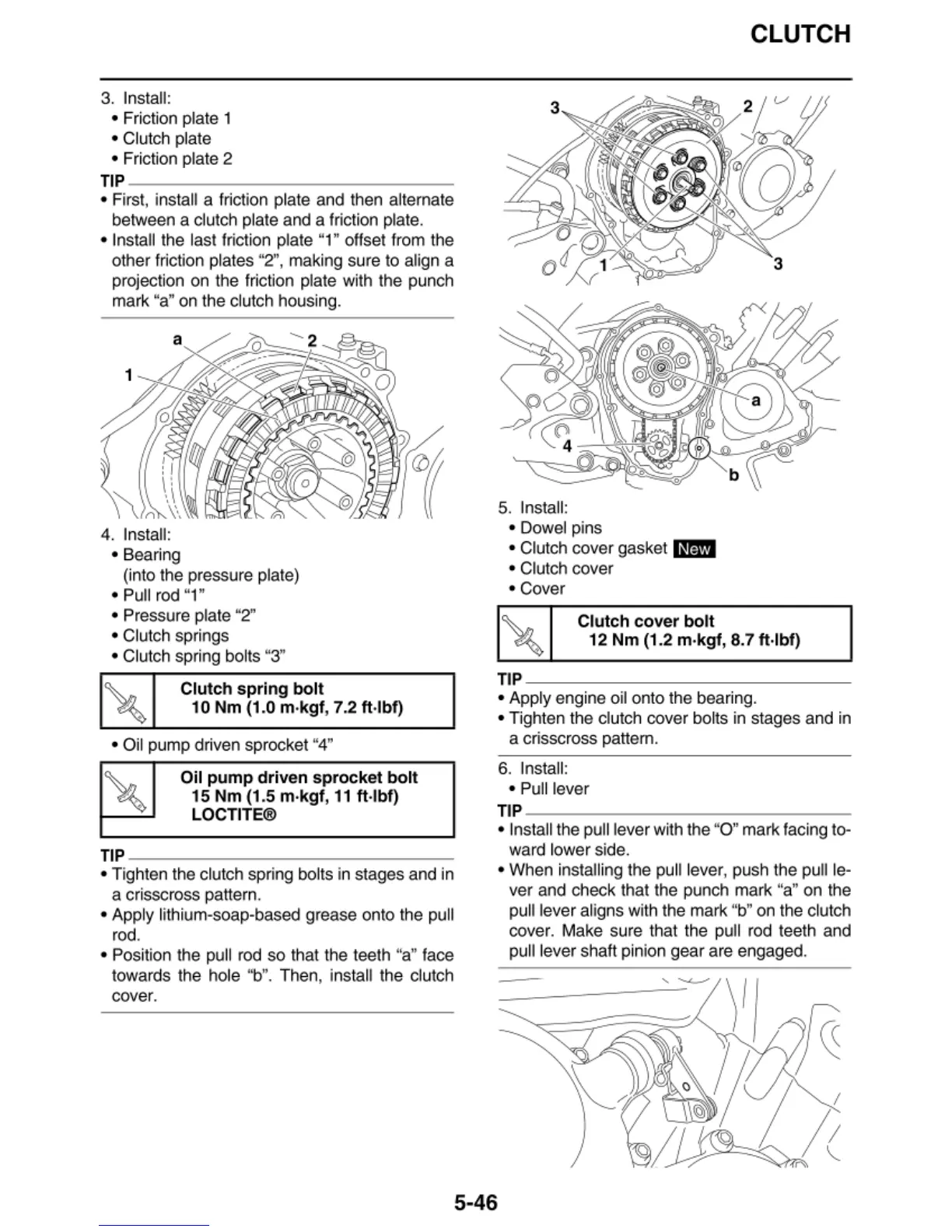

3. Install:

• Friction plate 1

• Clutch plate

• Friction plate 2

TIP

~~~~~~~~~~~~~~

• First, install a

fri

ction plate and then alternate

between a c

lu

tch plate and a friction plate.

• Install the last friction plate "1" offset from the

other friction plates

"2",

maki

ng

su

re

to align a

projection on t

he

fric

ti

on plate with the pu

nc

h

mark "a" on t

he

clutch housing.

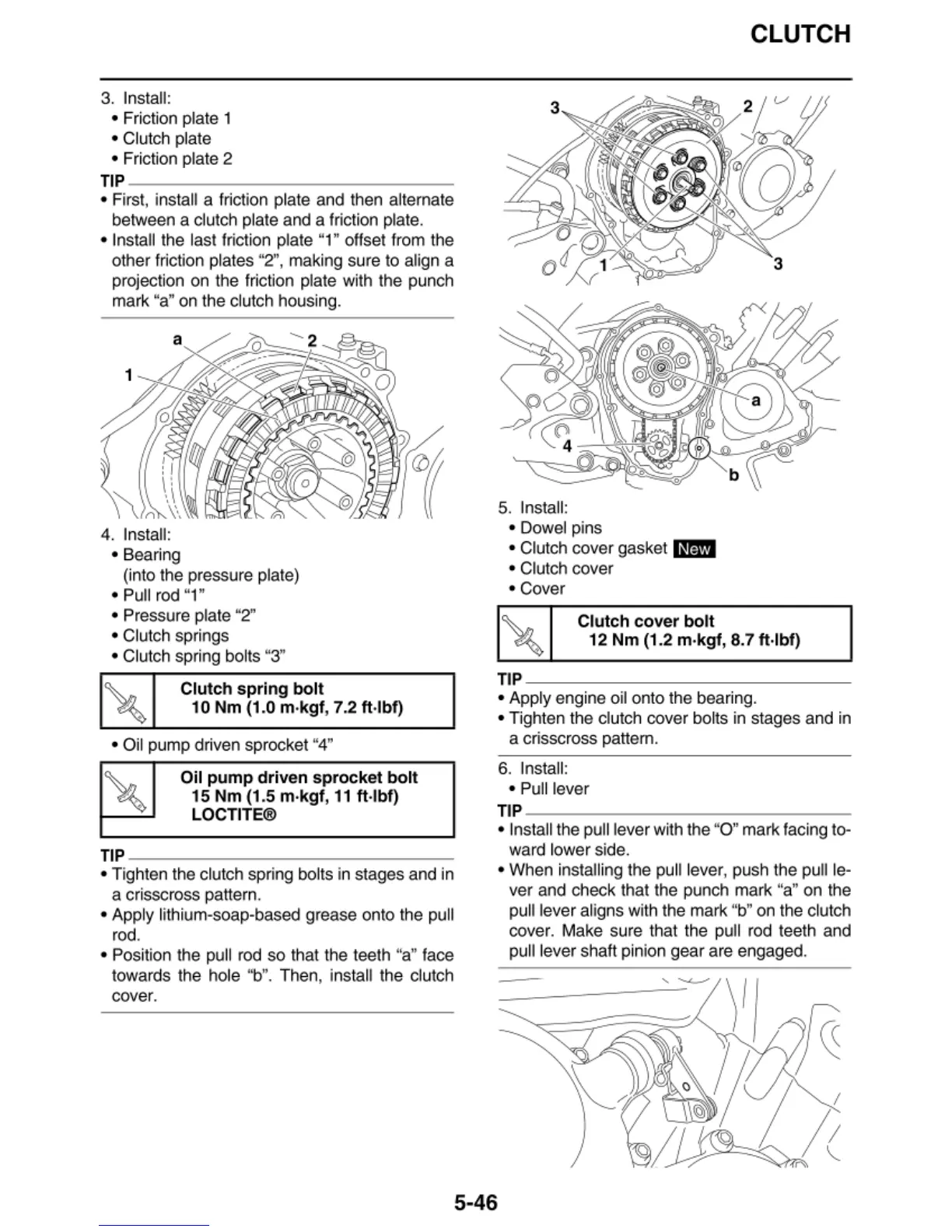

4. Install:

• Bea

rin

g

(into the pressure plate)

• Pull rod "1"

• Pressure plate "2"

• Clutch springs

• Clutch spri

ng

bol

ts

"3"

Clutch

spring

bolt

10 Nm (1.0 m·

kgf

, 7.2 ft·lbf)

• Oil pump driven sprocket "4"

Oil

pump

driven

sprocket

bolt

15 Nm

(1

.5 m·

k,gf,

11

ft·lbf)

LOCTITE®

TIP

~~~~~~~~~~~~~~

• Tighten the clutch sp

ring

bol

ts

in stages and in

a crisscross pa

tt

ern.

• Apply li

thi

um-soap-based grease onto the pu

ll

rod.

•

Pos

ition the pu

ll

rod

so

that

th

e teeth "a" face

towards the

ho

le

"b".

Then, install the c

lu

tc

h

cover.

5.

Insta

ll

:

• Dowel pins

• Clut

ch

cover gasket

IH¥j

• Clut

ch

cover

• Cover

Clutch

cover

bolt

CLUTCH

12

Nm

(1.2 m·kgf, 8.7 ft·lbf)

TIP

~~~~~~~~~~~~~~-

• Ap

pl

y en

gi

ne oil onto the bea

ri

ng.

• Tighten the clut

ch

cover bol

ts

in stages and in

a crisscross pattern.

6.

Install:

•

Pu

ll

lever

TIP

~~~~~~~~~~~~~~

• Insta

ll

th

e pull lever with the "O" mark facing to-

ward lower side.

• When installing the pull lever, push the pull le-

ver and check that the punch mark "a" on the

pull lever aligns wi

th

the mark "b" on the clutch

cover. Make sure that the pull rod teeth and

pull lever shaft pinion gear are engaged.

5-46

Loading...

Loading...