2-15

E

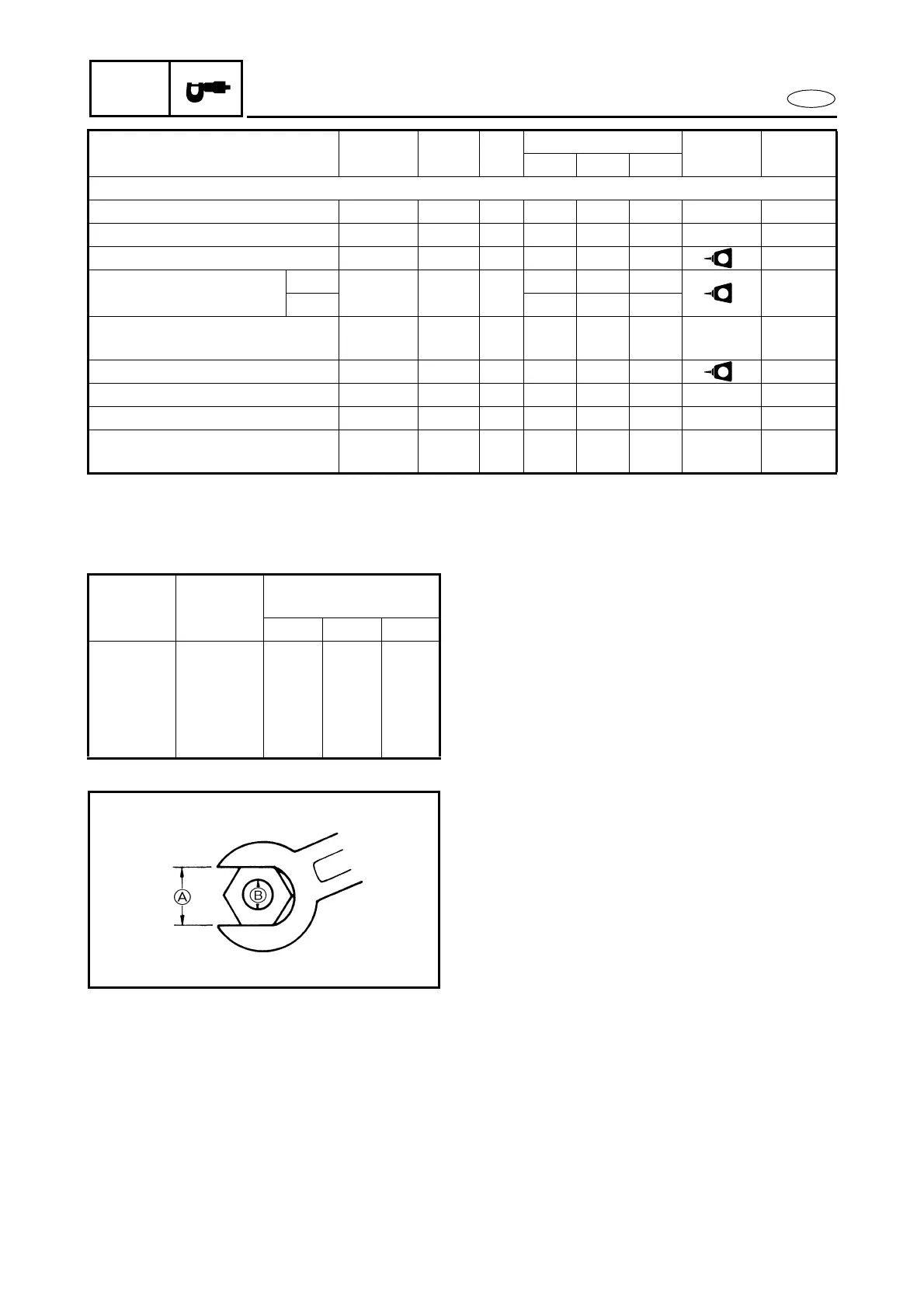

SPEC

TIGHTENING TORQUES

Electrical

Fuse box Nut — 2 17 1.7 12 7-2

Fuse box bracket Nut — 4 15 1.5 11 7-2

ECM Bolt M6 4 4.0 0.4 2.9

572

LT

7-7

Bracket

1st

Bolt M8 2

8.80.886.4

572

LT

7-7

2nd 18 1.8 13

Slant detection switch

Tapping

screw

ø6 2 3.90.392.8 7-2

Rectifier/regulator Bolt M8 2 4.0 0.4 2.9

572

LT

7-7

Brush assembly/spacer Nut — 1 8.8 0.88 6.4 7-39

Starter motor rear cover Bolt M5 2 6.4 0.64 4.6 7-39

Remote control transmitter

cover

Tapping

screw

ø2 6 0.1 0.01 0.1 7-64

Part to tightened

Part

name

Thread

size

Q’ty

Tightening torque

Remarks

Refer to

page

N•mkgf•mft•lb

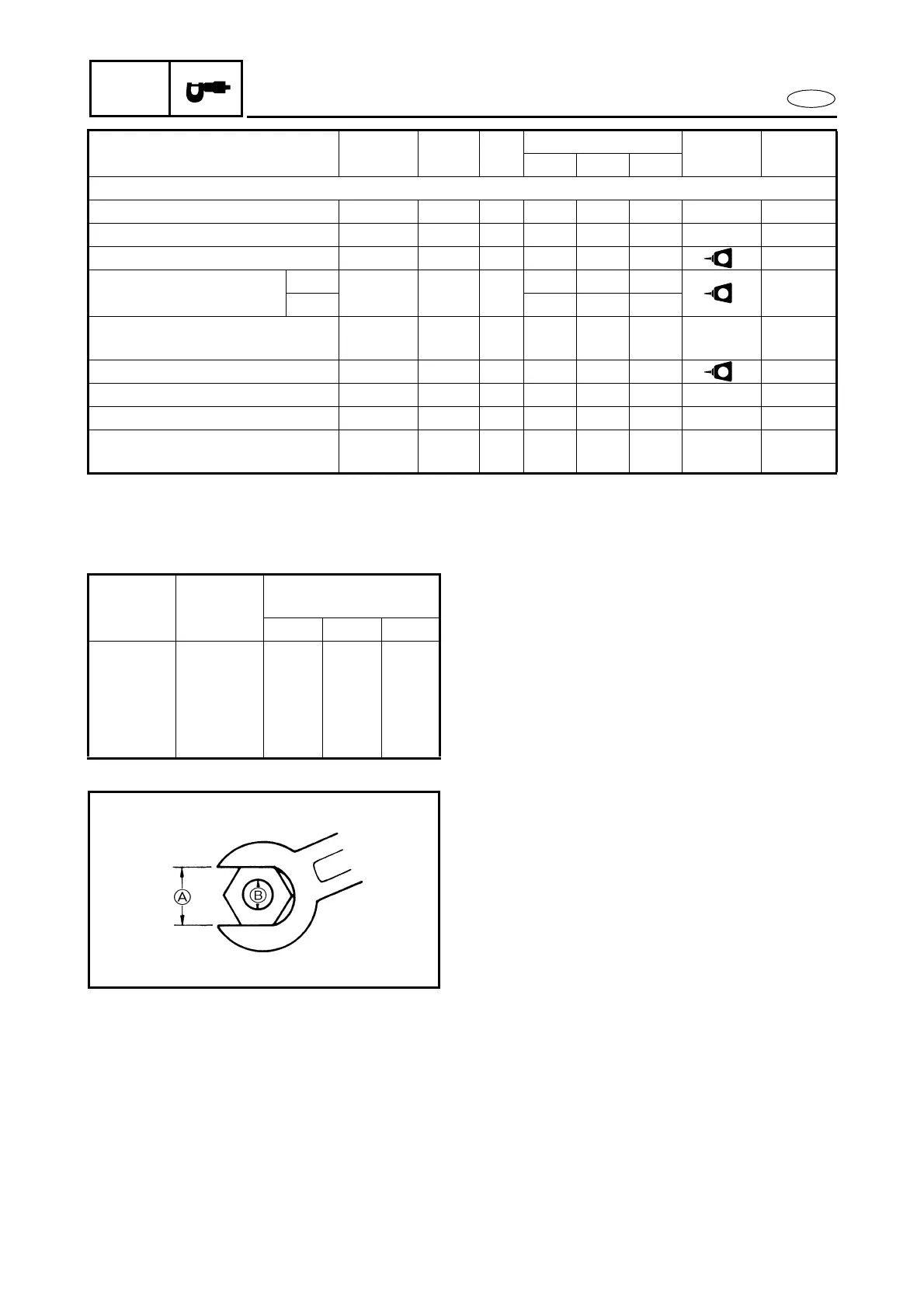

GENERAL TORQUE

This chart specifies tightening torques for stan-

dard fasteners with a standard ISO thread

pitch. Tightening torque specifications for spe-

cial components or assemblies are provided in

applicable sections of this manual. To avoid

warpage, tighten multi-fastener assemblies in

a crisscross fashion and progressive stages

until the specified tightening torque is reached.

Unless otherwise specified, tightening torque

specifications require clean, dry threads.

Components should be at room temperature.

Nut

A

Bolt

B

General torque

specifications

N•mkgf•mft•lb

8 mm M5 5.0 0.5 3.6

10 mm M6 8.0 0.8 5.8

12 mm M8 18 1.8 13

14 mm M10 36 3.6 26

17 mm M12 43 4.3 31

Loading...

Loading...