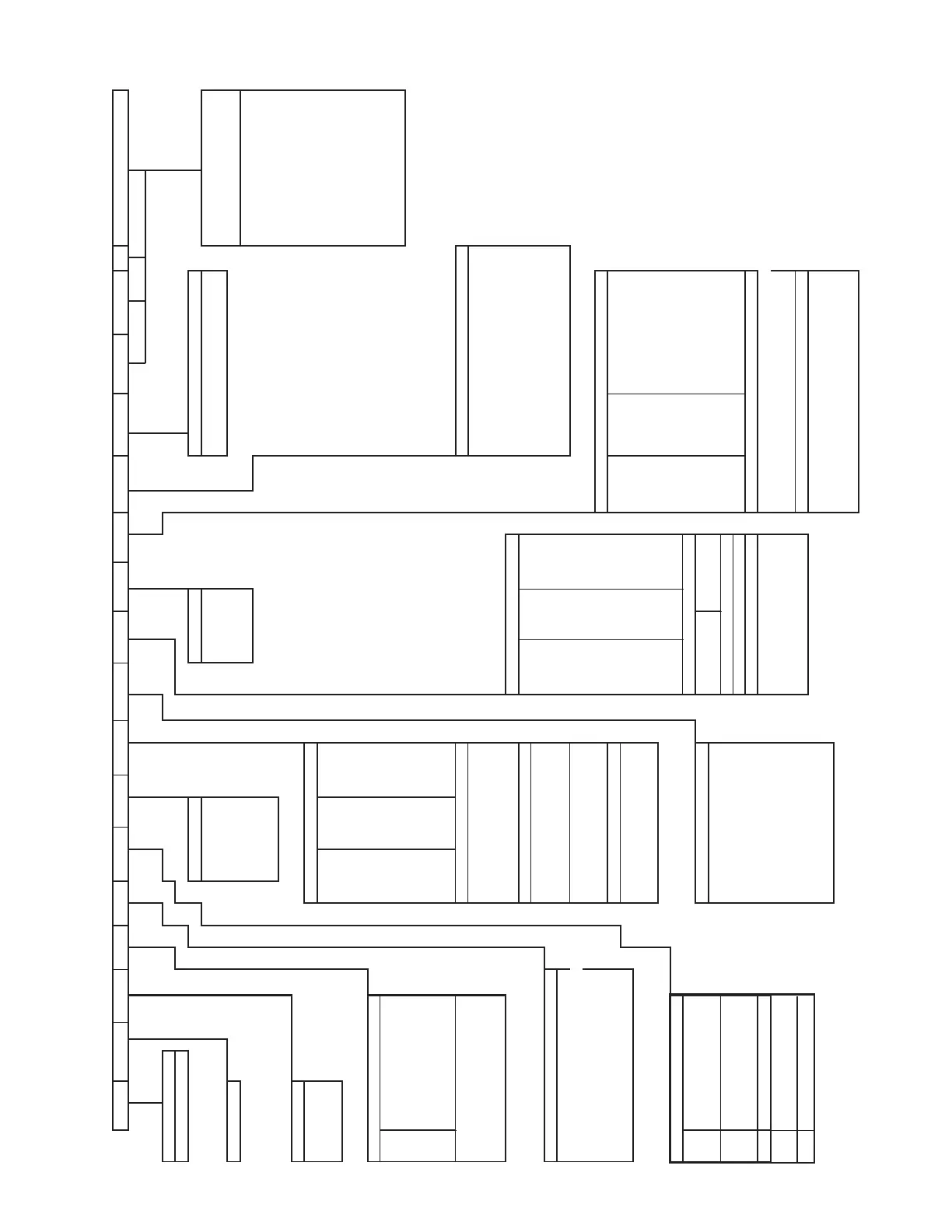

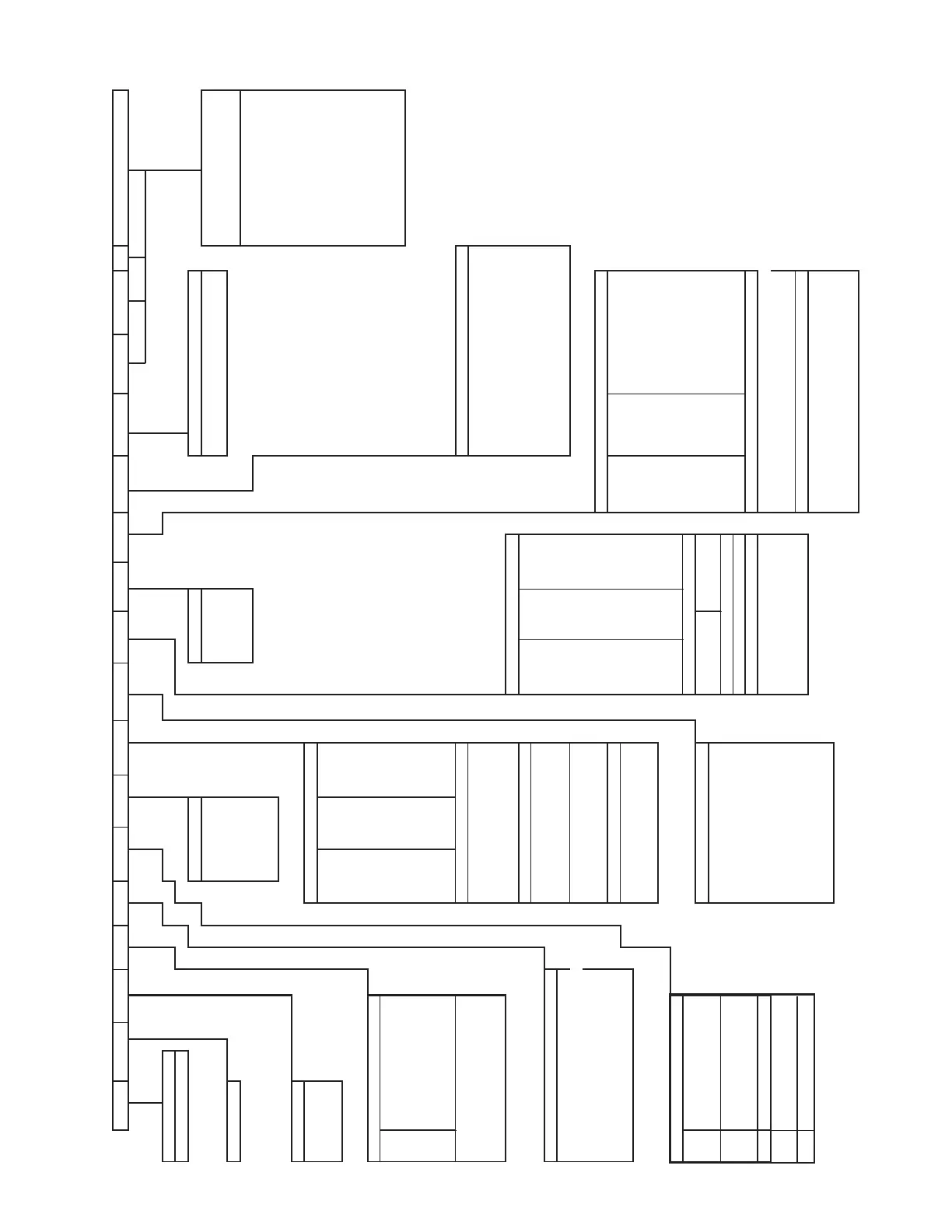

JOHNSON CONTROLS

4

FORM 100.50-NOM7 (808)

NOMENCLATURE

1 2 3 4

VOLTAGE CONTROL

2 = 208/230-3-60

G = OPTILOGIC (ESG ONLY)

ADDITIONAL

3 = 380-3-60

U = IPU2 (FUTURE OPTION)

CONFIGURATION

4 = 460-3-60

OPTIONS

5 = 575-3-60

Cu/Cu Condenser Coil

7 = 380/415-3-50

Cu/Cu Evaporator Coil, Std or Hi Cap

(30T/40 Ton Only)

NOTES:

Power Exhaust VFD (Customer)

1. 108KW not available with 208/230V.

(see notes 3 & 7)

2. Standard efficiency motor meets Canadian

Individual condenser fan fusing

(See note 4)

inimum efficiency regulations mandated

A = A, F, I L = D, G, J W = D, E, J

in Canadian Energy Efficiency Regulations.

* Doors - std cabinet (4 Doors)

B = A, G, I M = B, F, I X = D, F, H

3. (VFD-CUSTOMER) = Wired for VFD

* Doors - premium cabinet (6 Doors)

C = A, F, J N = B, F, J Y = B, E, H

only; VFD will be customer supplied and

* Drain Pan - powder coat

D = A, G, J O = B, G, I Z = B, E, I

field installed. If VFD Power Exhaust is also

* Drain Pan - stainless steel

CONFIGURATION

E = A, E, H P = B, G, J 2 = B, E, J

specified, it will also be cust supplied.

A = 1, 2 1 - BOTTOM RETURN F = A, E, I Q = C, F, I 3 = B, F, H

4. VAV ID Blower requires hot gas bypass .

* You must make selections

B = 1, 4 2 - BOTTOM SUPPLY G = A, E, J R = C, F, J 4 = C, E, H

5. Power Exhaust and Barometric Relief is

in these options for every unit

C = 1, 5

3 - END RETURN

(5)

H = A, F, H S = C, G, I 6 = C, E, I

not available in end return configuration.

D = 3, 2 4 - REAR SUPPLY I = D, F, I T = C, G, J 7 = C, E, J

6. FC1 (Class I) blowers are limited in HP

Hi Cap evap is for 30/40T R-22 only

E = 3, 4 5 - FRONT SUPPLY J = D, F, J U = D, E, H 8 = C, F, H

applications, See notes in Supply Fan.

F = 3, 5 K = D, G, I V = D, E, I 9 = D, G, H

Air foil fan only available on Cooling Only.

FRONT SUPPLY - COOLING ONLY

Air Volume

Contact engineering for air foil

HOT WATER, STEAM & ELECTRIC HEAT -

A = CV

applications.

BOTTOM SUPPLY ONLY

B = VAV (VFD-FACTORY INSTALLED)

7. Only available with Hi EFF motors

GAS HEAT - BOTTOM OR REAR SUPPLY ONLY

(3)

Supply Fan (See note 6)

E = FORWARD CURVE FAN Class I B = 2, 3, 5, 7 M = 1, 3, 6, 8 X = 2, 4,0 , 7

HEAT SOURCE * 3RD Q/2008

F = FORWARD CURVE FAN Class II C = 1, 4, 5, 7 N = 2, 3, 6, 8 Y = 1, 3, 9, 8

N = NATURAL GAS, STAGED G = AIR FOIL FAN [Always Class II

D = 2, 4, 5, 7 O = 1, 4, 6, 8 Z = 2, 3, 9, 8

S = NATURAL GAS, STAGED, SS HEAT EXCHANGER Class I blower is limited to 15 HP in 25/30 Ton. E = 1, 3, 6, 7 P = 2, 4, 6, 8 2 = 2, 4, 9, 8

E = ELECTRIC HEAT Class I blower is limited to 20 HP in 40 Ton. F = 2, 3, 6, 7 Q = 1, 3, 9, 7 3 = 1,3,0,8

C = COOLING ONLY Class II blowers are not HP limited. G = 1, 4, 6, 7 R = 2, 3, 9, 7 4 = 2,3,0,8

(See note 5)

W = HOT WATER COIL

Blower Mount Isolation

H = 2, 4,6 , 7 S = 1, 4, 9, 7 5 = 1,4,0,8 A = BARO J = 2, 5 S = A, 3

X = STEAM COIL H = Neoprene isolators I = 1, 3, 5, 8 T = 2, 4, 9, 7 6 = 2,4,0,8 B = 1, 3 K = 2, 6 T = A, 4

I = 1 inch deflection spring J = 2, 3, 5, 8 U = 1, 3, 0, 7 7 = 1,4,9,8 C = 1, 4 L = 2, 7 U = A, 5

J = 2 inch deflection spring K = 1, 4, 5, 8 V = 2, 3, 0, 7 D = 1, 5 M = 2, 8 V = A, 6

9 = Non-S

td E = 1, 6 N = NONE W = A, 7

HEAT CAPACITY

F = 1, 7 O = 1, 9 X = A, 8

4 = 40 KW

Condenser Coil Head Press. Ctrl.

G = 1, 8 P = 1, 0 Y = A, 9

E

8 = 80 KW

(See note 2)

1 = STANDARD 7 = YES H = 2, 3 Q = 2, 9 Z = A, 0

1 = 108 KW

(1)

1 = 10 HP ST

2 = TECHNICOAT 8 = NO I = 2, 4 R = 2, 0 2 = 8,000 CFM ERV

C

0 (ZERO) NO HEAT

2 = 15 HP ST

Piping

(See note 4)

3 = 13,000 CFM ERV

W

1 = 1 ROW COIL

3 = STANDARD 4 = HOT GAS BYPASS 9 = Non-Standard Config

2 = 2 ROW COIL

4 = 25 HP STD

(Except 25 Ton)

Evaporator Coil Power Exhaust

X

1 = 1 ROW COIL

5 = 10 HI-EFF 5 = STANDARD 1 = MODULATING DAMPERS A = VFD, MODULATING MOTOR

6 = 15 HI-EFF 6 = HI-CAP (30T/40T R22 ONLY) 2 = NON-MOD. (ON/OFF)

7 = 20 HI-EFF 9 = STD W/TECHNICOAT

8 = 25 HI-EFF

(Except 25 Ton)

0 = HI-CAP W/T-COAT (30T/40T R22)

Motor

9 = 7.5 HP STD

(25 Ton Only)

0 = 5 HP HI-EFF

(25 Ton Only)

9 = 5 HP

(25 Ton Only)

0 = 7.5 HI-EFF

(25 Ton Only)

3 = 7.5 HP 6 = 7.5 HP HI-EFF

4 = 10 HP 7 = 10 HP HI-EFF

5 = 15 HP

(Except 25 Ton)

8 = 15 HP HI-EFF

(Except 25 T)

E = NONE

F = DUAL ENTHALPY, Std no seals type

G = SINGLE ENTHALPY, Std no seals type

H = DRY BULB TEMP, Std no seals type

C, = DRY BULB TEMP, Low Leak seals type

Config

A

13

G

14

W = 1, 4, 0, 7

A = DUAL ENTHALPY, Low Leak seals type

D = MANUAL DAMPER (Not w/PE), Std. no seals type

B, = SINGLE ENTHALPY, Low Leak seals type

3

3

N

5

A

4

3

2

3

6

4

7

C

12

B

8

1

9

A

10

A

11

J

1

= UNDER FLOOR R410A

= 25 TON

L = 2, 4, 5, 8

B = 65%

D = 2" HI-EFF

A = 1, 3, 5, 7

= 40 TON

N,S 3 = 267 MBH

5 = 533 MBH

8 = 800 MBH (40T ONLY)

Loading...

Loading...