JOHNSON CONTROLS

72

FORM 100.50-NOM7 (808)

Service

tion, the technician can insert a tee into the pneumatic

tubing to connect a manometer and verify the pressure

being applied to the transducer. Once this pressure is

known, a comparison can be made of the duct pressure

vs. output volts DC from the transducer. A practical and

quick check of this transducer can also be accomplished

by removing the pneumatic tubing lines from both high

and low side connections on the transducer. Since both

of the inputs will now be exposed to the same pressure,

the dierential pressure will be zero, and output 2.5

VDC according to the Table 10.

TABLE 10 – BUILDING PRESSURE TRANSDUCER

OUTPUT TABLE

BUILDING PRESSURE TRANSDUCER OUTPUT

DIFFERENTIAL INPUT OUTPUT VOLTAGE

PRESSURE - IWG - VDC

-0.50 0.00

-0.40 0.50

-0.30 1.00

-0.20 1.50

-0.10 2.00

0.00 2.50

0.10 3.00

0.20 3.50

0.30 4.00

0.40 4.50

0.50 5.00

FIG. 23 – MOD-UNT

00492VIP

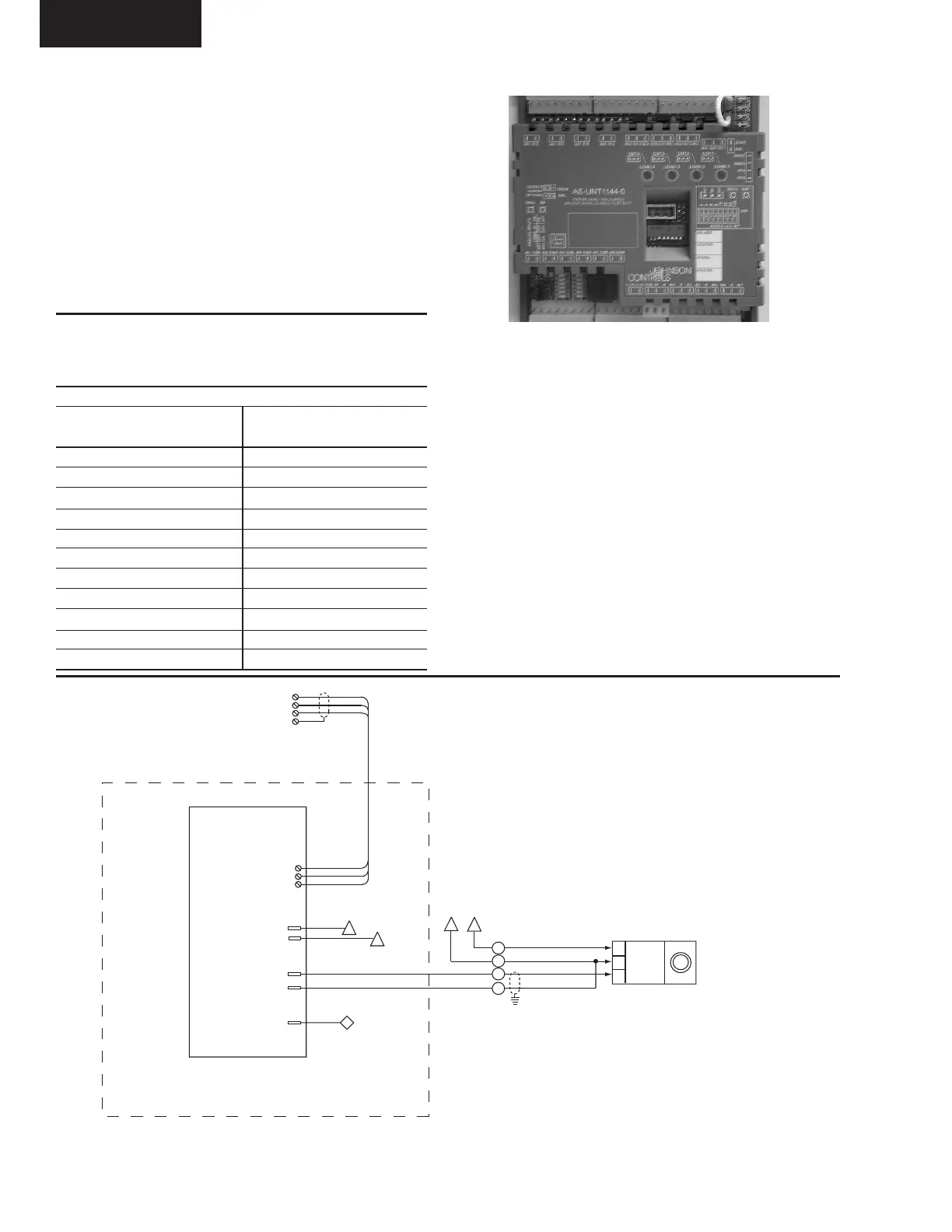

FIG. 24 – MOD-UNT WIRING DIAGRAM

4ACU (OPTIONAL)

FLEXSYS BYPASS

DAMPER ACTUATO

24 VAC

COM

0-10 VDC

SECONDARY CONTROLLER AND COMMUNICATIONS CABLE

REQUIRED FOR UNITS EQUIPPED FOR FLEXSYS OPERATION

SECONDARY

CONTROLLER

(MOD-UNT)

{

TB3

1

2

3

4

N2+

N2-

N2 GND

SHIELD

{

N2+

N2-

N2 GND

TB4

100

COM

W20

W23

24 VAC(W56)

RTN (W55)

W36

EVR

27

LINE # 308

LINE # 308

(TO LINE # 305)

CTB2

4

3

2

1

47

48

49

50

LD07414UU

Loading...

Loading...