JOHNSON CONTROLS

307

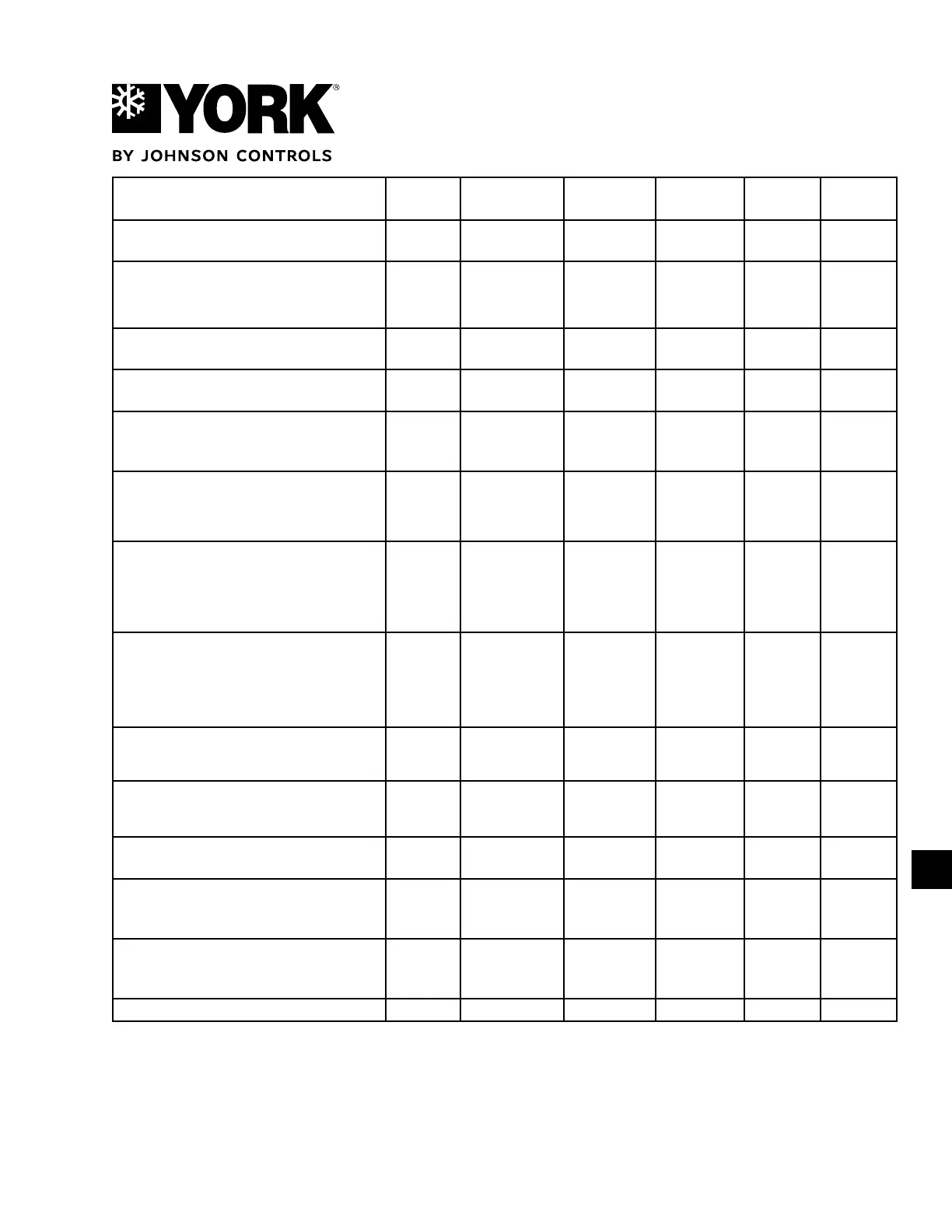

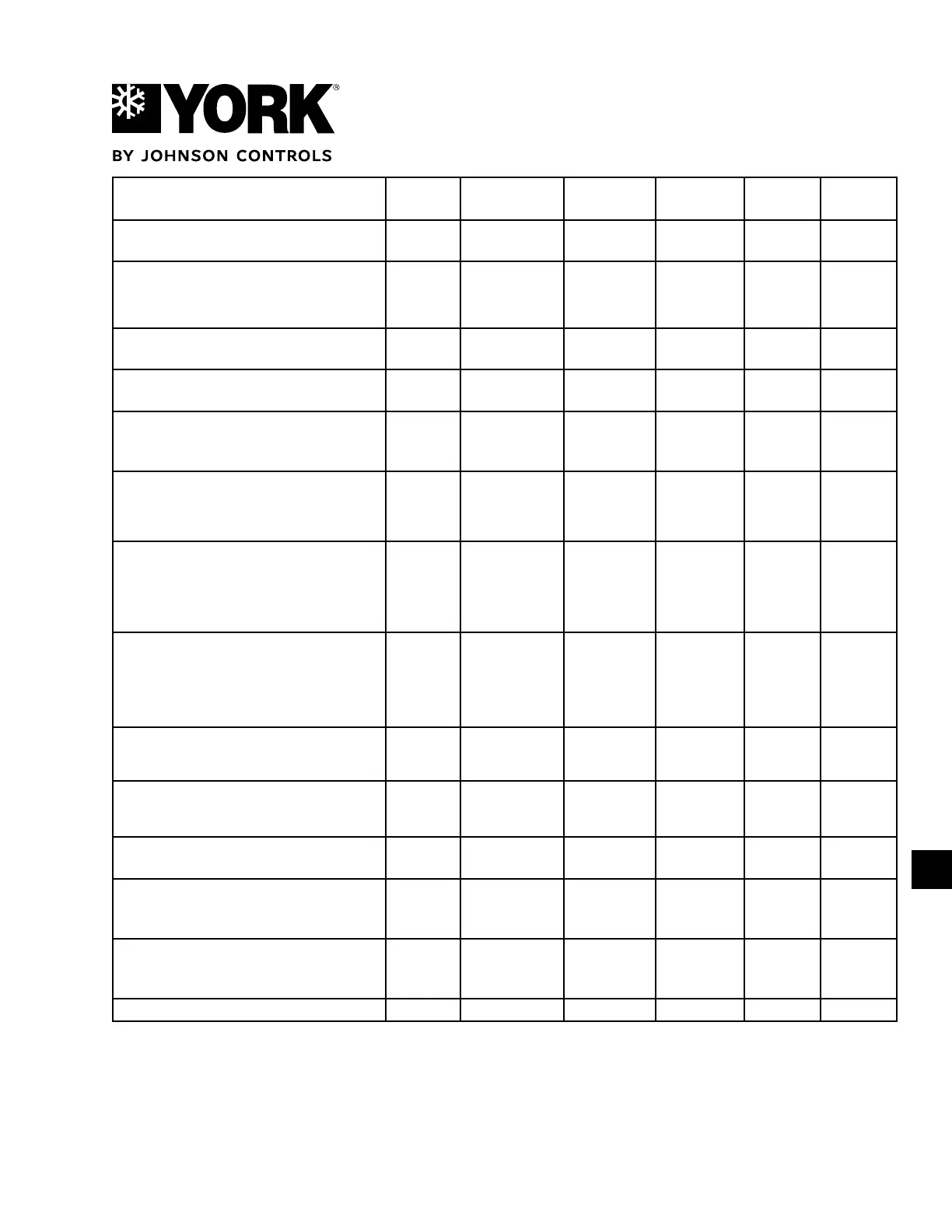

SECTION 9 - MAINTENANCE

FORM 201.23-NM2

ISSUE DATE: 09/25/2020

9

PROCEDURE WEEKLY QUARTERLY

SEMI-

ANNUALLY

ANNUALLY

EVERY 5

YEARS

EVERY *

HOURS

Check Oil Level in Oil Separator Sight

Glass.

X

Check Liquid Line Sight Glass/ Moisture

Indicator.

X

Record System Operating Temperatures

& Pressures.

X

Check Condenser Coils for dirt / debris

and clean as necessary.

X

Check Programmable Operating

Setpoints and Safety Cutouts. Assure

they are correct for the application.

X

Check Compressor and Evaporator

Heater operation.

X

Check for dirt in the Panel. Check Door

Gasket sealing integrity.

X

**Check Superheat on the Evaporator

and the Economizer feed to the Compres-

sor.

X

**Check Condenser Subcooling. X

**Leak check the Chiller. X

**Sample Compressor Oil, check for Acid,

and replace if necessary.

X

**Disconnect Power Source and Lock

Out. Check tightness of Power Wiring

connections.

X

Check Glycol concentration on Low Temp.

or other applications where freezing may

be a problem.

X

VSD Glycol Change. X

* Reserved for customer use for any special site requirements.

** This procedure must be performed at the specic time by an industry certied technician who has been

trained and qualied to work on this type of equipment. A record of this procedure be successfully carried out should be maintained on le by

the equipment owner should proof of adequate maintenance be required at a later date for warranty purposes.

MAINTENANCE REQUIREMENTS

FOR YCIV CHILLERS

Loading...

Loading...