JOHNSON CONTROLS

55

SECTION 6 - TECHNICAL DATA

FORM 201.23-NM2

ISSUE DATE: 09/25/2020

6

The cooler is designed in accordance with

RI-590-92 which allows for an increase in

pressure drop of up to 15% above the design value

shown on pages 48-51. Debris in the water may

also cause additional pressure drop.

When using glycol solutions, pressure drops are

higher than with water (see correction factors to be

applied when using glycol solutions). Special care

must be taken not to exceed the maximum flow

rate allowed.

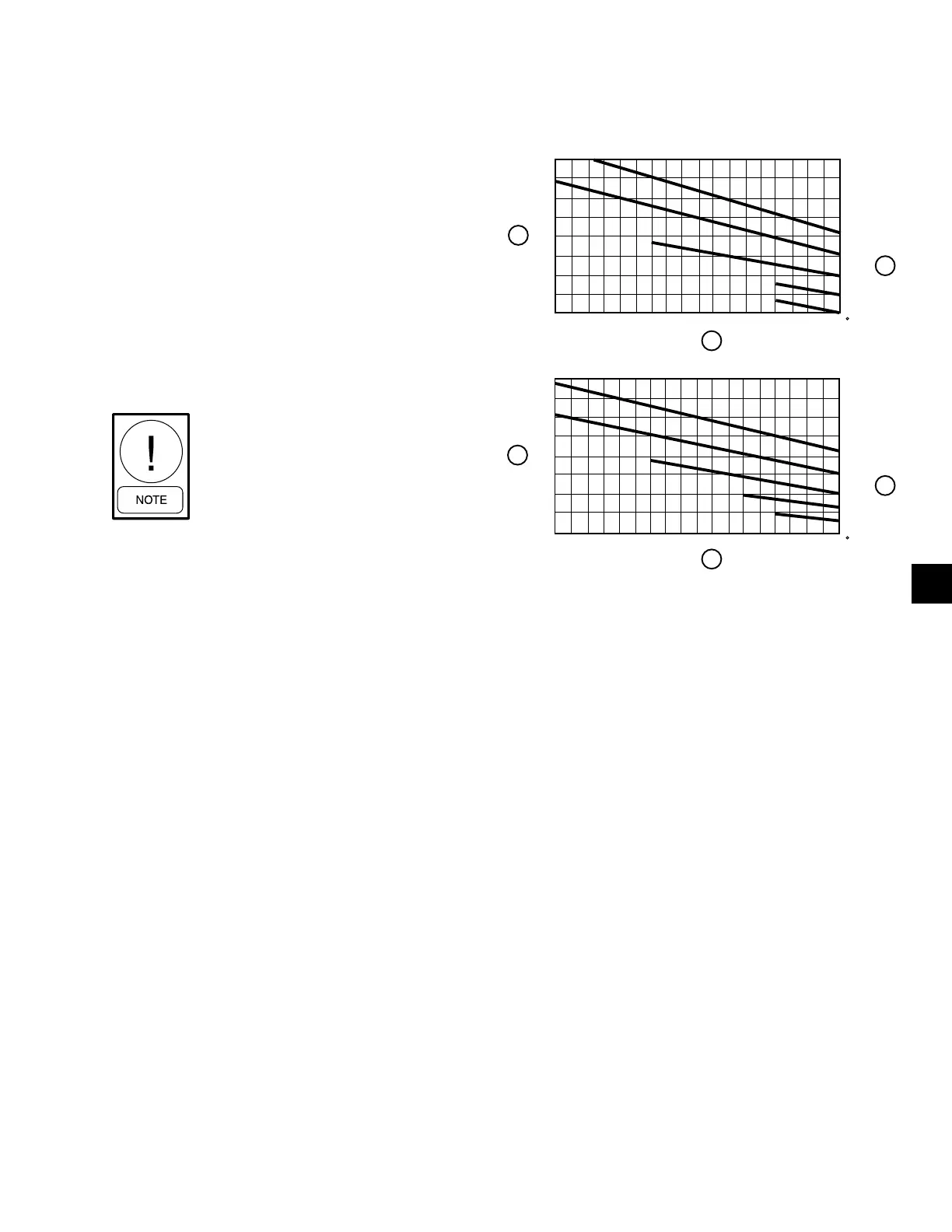

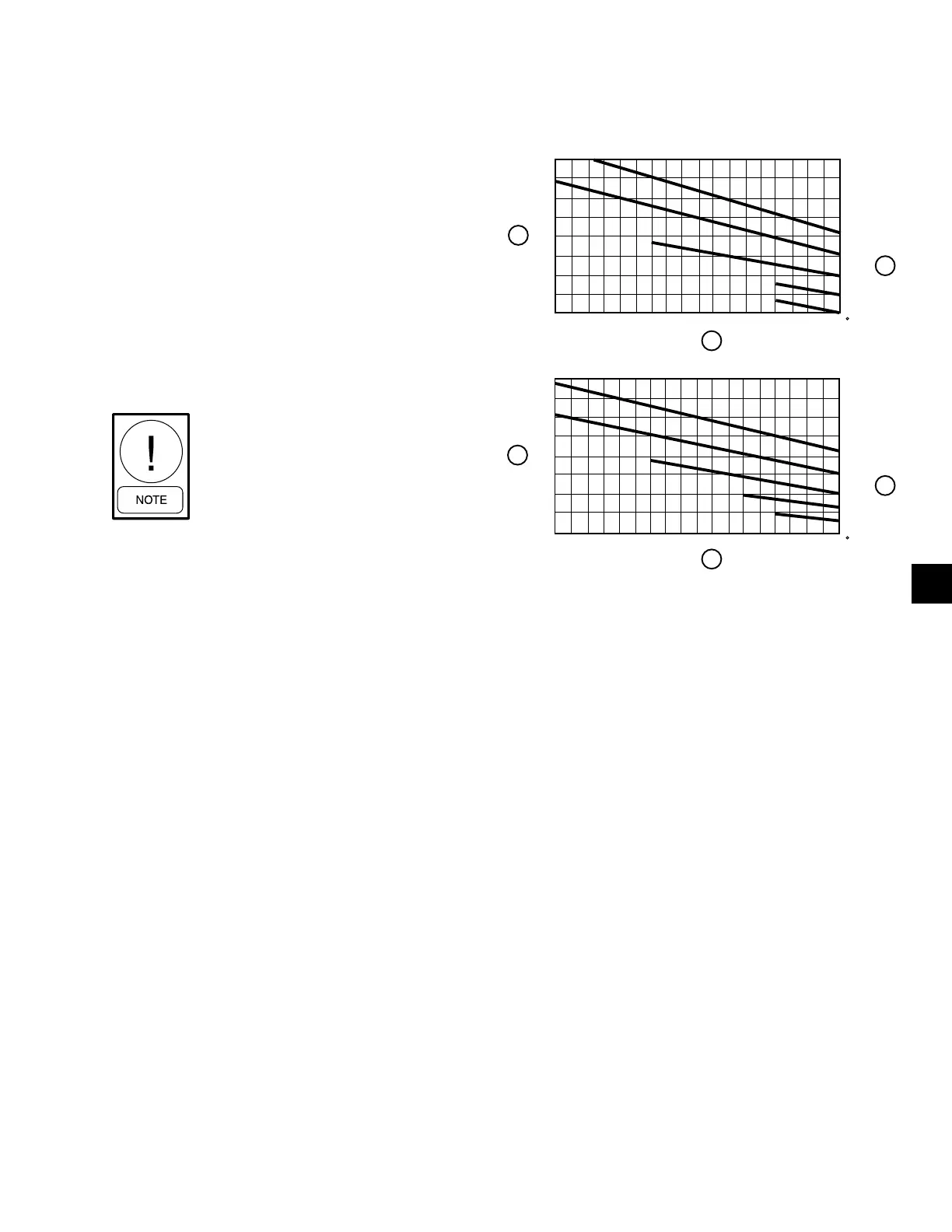

A= Correction Factor

B= Mean Temperature through Cooler

C= Concentration W/W

Excessive flow, above the max. GPM,

will damage the evaporator.

PROPYLENE GLYCOL

ETHYLENE GLYCOL

GLYCOL CORRECTION FACTORS

A

A

B

B

1.8

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1.0

1.45

1.40

1.35

1.30

1.25

1.20

1.15

1.10

1.05

50%

40%

30%

20%

10%

50%

40%

30%

20%

10%

C

C

-10 -8 -6 -4 -2 0 2 4 6 8 C

-10 -8 -6 -4 -2 0 2 4 6 8 C

LD10500A

GLYCOL CORRECTION FACTORS

The cooler is designed in accordance with ARI-590-

92 which allows for an increase in pressure drop of

up to 15% above the design value shown on Pages 63

through 66. Debris in the water may also cause addi-

tional pressure drop.

When using glycol solutions, pressure drops are higher

than with water (see correction factors to be applied

when using glycol solutions). Special care must be

taken not to exceed the maximum flow rate allowed.

A = Correction Factor

B = Mean Temperature through Cooler

C = Concentration WIW

Excessive ow, above the max. GPM, will

damage the evaporator.

Loading...

Loading...