3 Maintenance

3.2.2. Maintenance schedule

1433HAC022033-001 Revision: K

© Copyright 2004-2011 ABB. All rights reserved.

3.2.2. Maintenance schedule

General

The robot must be maintained regularly to ensure proper function. The maintenance activities

and intervals are specified in the table below.

Non-predictable situations also give rise to inspections of the robot. Any damages must be

attended to immediately!

The inspection intervals do not specify the life of each component.

Values for these are specified in the section Expected component life on page 149

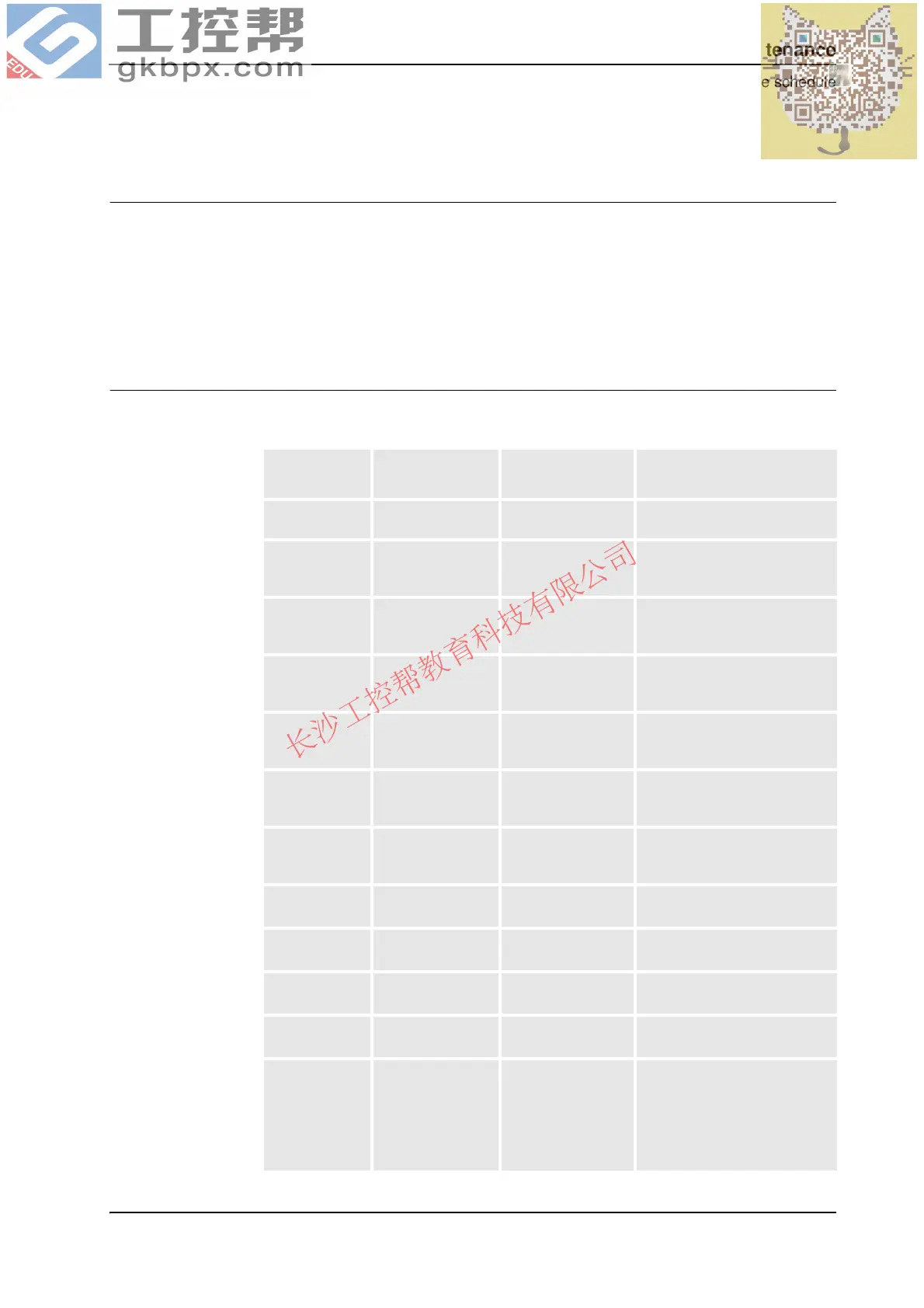

Activities and intervals, standard equipment

The table below specifies the required maintenance activities and intervals:

Maintenance

activity

Equipment Interval Detailed in section

Cleaning Robot - • Cleaning, robot on page

233

Inspection Axis 1 gearbox,

oil level

Every:

12 months

• Inspection, oil level

gearbox axis 2 on page

153

Inspection Axis 2 gearbox,

oil level

Every:

12 months

• Inspection, oil level

gearbox axis 2 on page

153

Inspection Axis 3 gearbox,

oil level

Every:

12 months

• Inspection, oil level

gearbox axis 3 on page

156

Inspection Axis 4 gearbox,

oil level

Every:

12 months

• Inspection, oil level

gearbox axis 4 on page

158

Inspection Axis 5 gearbox,

oil level

Every:

12 months

• Inspection, oil level,

gearbox axis 5 on page

161

Inspection Axis 6 gearbox,

oil level

Every:

12 months

• Inspection, oil level

gearbox axis 6 on page

164

Inspection Balancing device Every:

•6 months

• Inspection, balancing

device on page 168

Inspection Robot harness Every:

12 months

4)

• Inspection, cable

harness on page 174

Inspection Information labels Every:

• 12 months

• Inspection, information

labels on page 187

Inspection Dampers Every:

• 12 months

• Inspection, damper

axes 2-5 on page 181

Inspection Mechanical stop,

axis 1

Every:

• 12 months

• Inspecting, mechanical

stop pin, axis 1 on page

177

• Inspection, mechanical

stop, axes 1, 2 and 3 on

page 179

Continues on next page

Loading...

Loading...