S800 I/O Station Data Scanning Section 3 Technical Data and Performance

138 3BSE015969-600 A

Calculation of Bus Cycle Time

How to calculate the Bus Cycle Time, see documentation for current master.

To calculate the Bus Cycle Time the following parameters for the I/O station shall

be used:

Number of input and output bytes.

MAX T

SDR

Maximum Station Delay of Responder in T

BIT

(Bit Time).

See GSD file.

S800 I/O Station Data Scanning

The ModuleBus data is scanned (read or written) cyclically, depending on the I/O

module configuration. To calculate the I/O scan cycle time in the FCI do as follows:

Totalize (number of module type x) * (used execution time for type x)

(see Table 28) if the value is a multiple of 2, add 2 to the value. Otherwise increase

the total value to the nearest higher multiple of 2 to get the I/O scan cycle time.

If CI810A or C1810B is used, the scan cycle time is increased by 25% and for

CI820 it is increased by 50%. If the value is a multiple of 2, add 2 to the value.

Otherwise increase the value to the nearest higher multiple of 2, to get the I/O cycle

time.

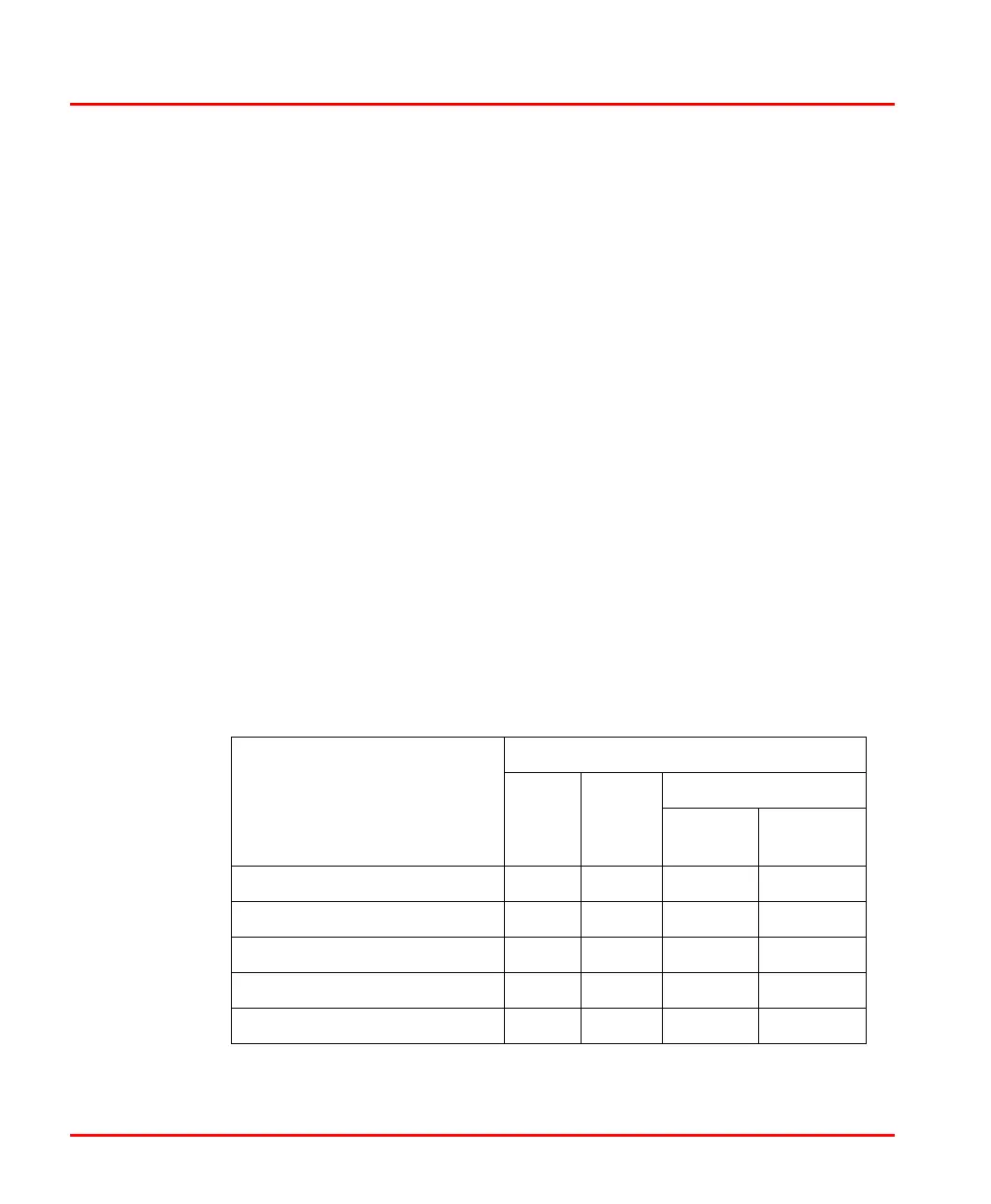

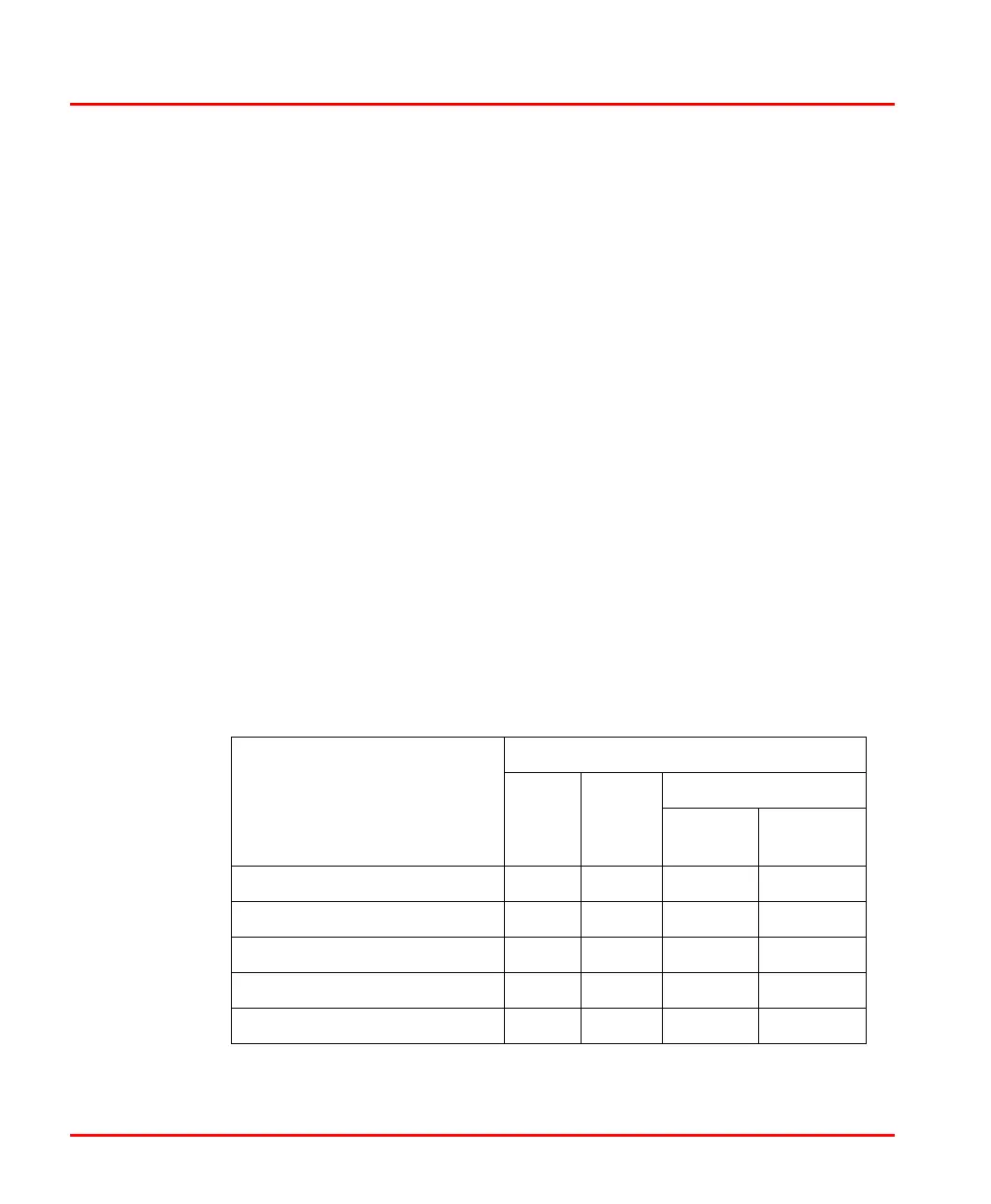

Table 28. I/O Scan Cycle Time in the FCI

Module Type

Execution Time Used in ms

CI801

CI810,

CI820

CI840

Single I/O

Redundant

I/O pair

AI801, AI810, AI890, AI895 3.00 3.00 3.00 -

AI820 1.50 1.50 1.50 -

AI825 1.50 - 1.50 -

AI830, AI830A, AI835, AI835A 0.40 0.40 0.40 -

AI893 0.40 - 0.40 -

Loading...

Loading...