13

5 ALARM MENU

The ALARM menu is used to view (and reset, if necessary) the alarm conditions that

may arise on the unit while it's working. The alarms are divided into various catego-

ries according to their seriousness. Remember that some of them can cause serious

damage to the unit so, before performing a reset, it's important to be sure about the

nature of the alarm and the reason it was triggered (contacting specialised techni-

cal personnel if necessary).

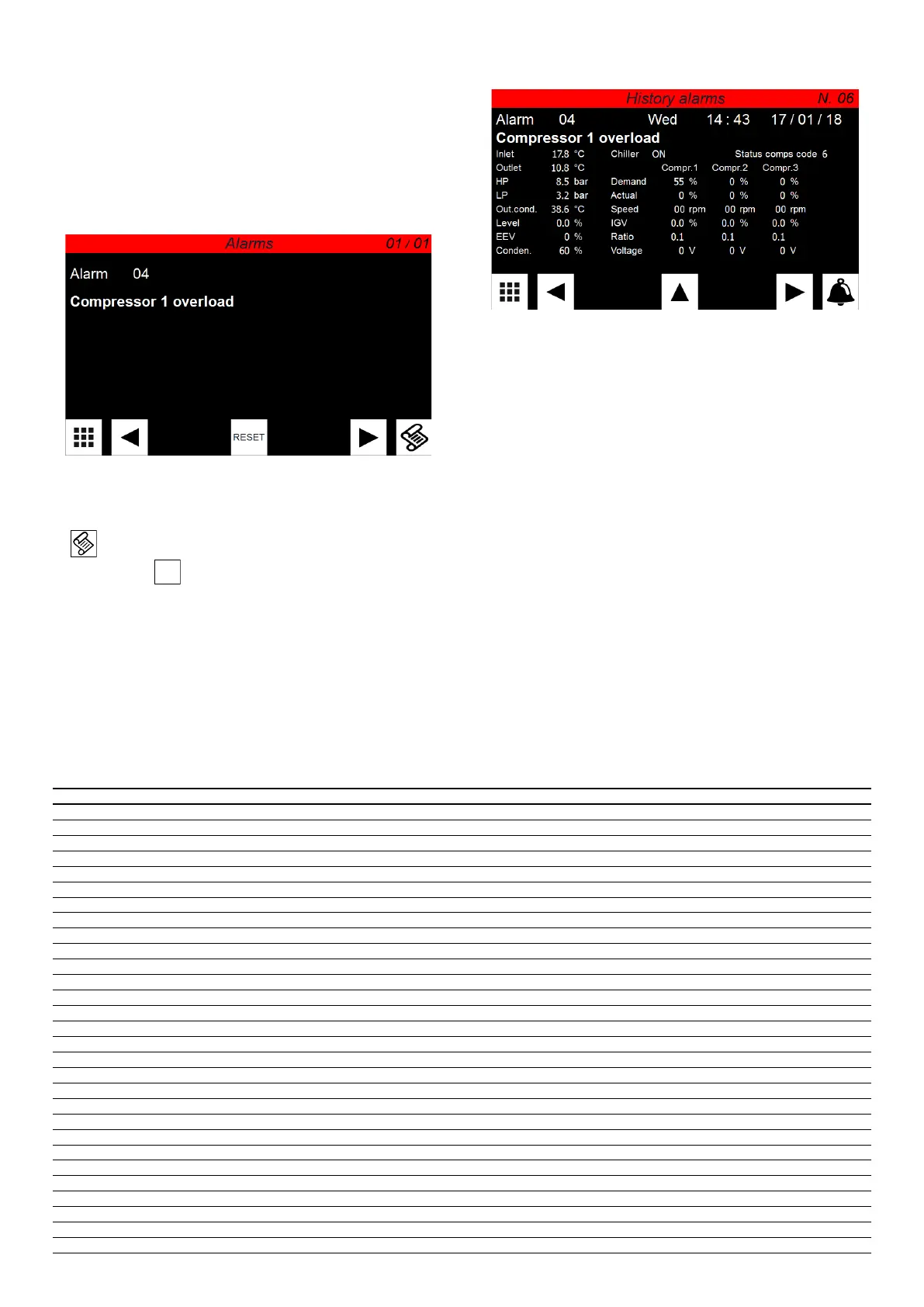

5.1 DISPLAYS ACTIVE ALARMS

— Indicates the currently active alarm number

— Indicates the total number of alarms currently active on the system

— Indicates the code of the currently active alarm

— Indicates the description of the currently active alarm

—

Go to alarms log

— Holding this key

Reset

for a few seconds resets the currently active alarm dis-

played (if the alarm includes a manual reset)

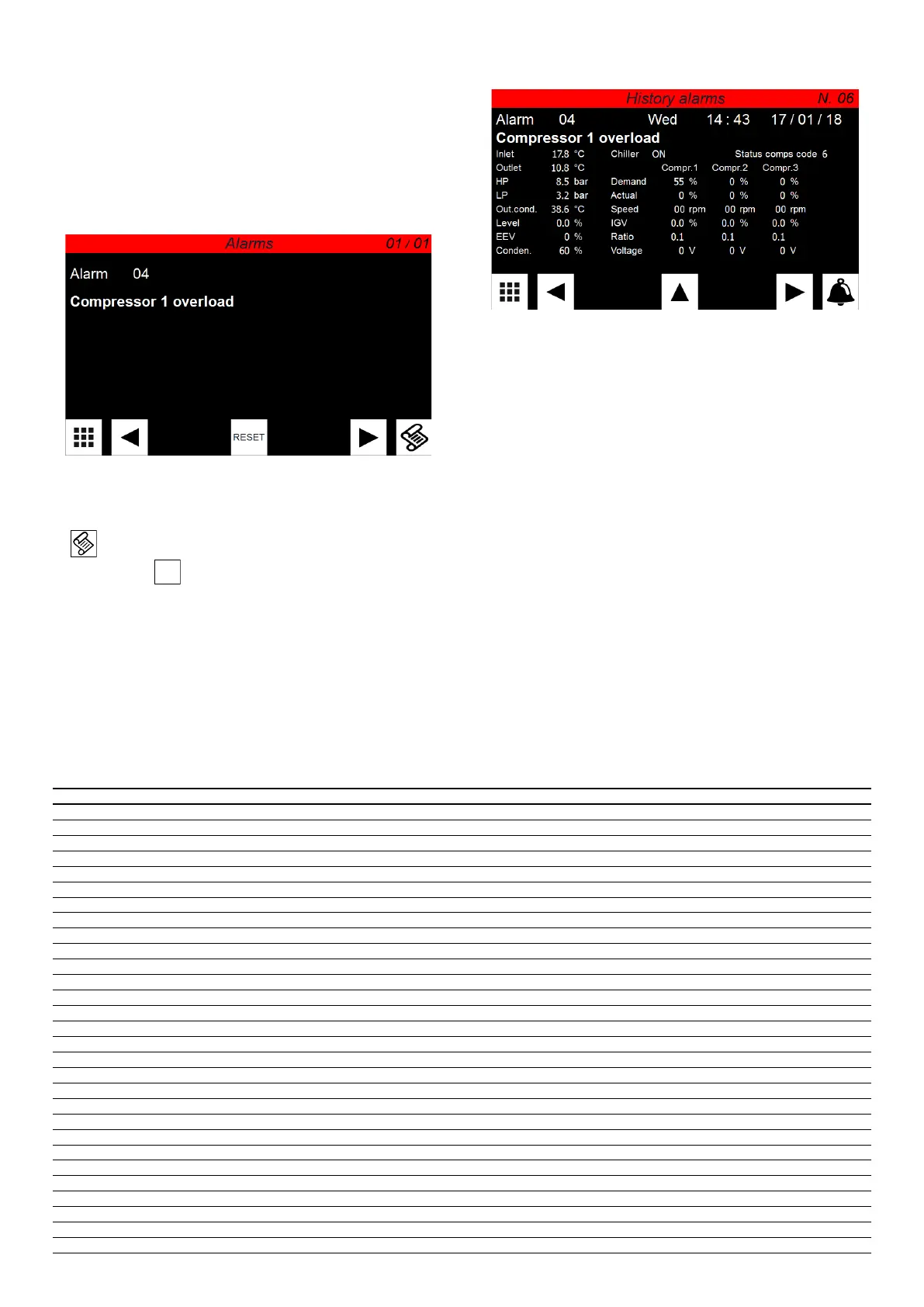

5.2 DISPLAYS ALARMS LOG

— It indicates the alarm number within the log (the log contains a maximum of

100 alarms, after which it saves the next ones overwriting the oldest ones)

— Date and time fo the alarm

— Alarm code and description

— Collection of the operating parameters of the unit recorded when the alarm

was generated

5.3 LIST OF ALARMS

Each alarm can have a specic type of reset, these types can be:

Auto (automatic) = the alarm disappears when the event which generated it ceas-

es;

Man (manual) = to resume normal operation, manual recognition by an operator

is required (via a touch screen or BMS);

Semi (semi-automatic) = the alarm is automatic, but if it is triggered more than 3

times in an hour then it becomes with manual reset;

TurboAL = characteristic alarm of Turbocor compressors. It is automatically reset

with the following procedure:

1. Turn o the aected compressor removing request;

2. Wait for a time of 30s (settable);

3. 10% power is given to the TurboCor;

4. The Turbocor resets the alarm;

5. The TurboCor repositions the IGV valve (approximately 120 s);

6. The pCO can turn on the TurboCor compressor again;

Code Description Reset

AL001 From digital input Auto

AL002 Phase or voltage monitor Auto (sw>=2.2.3)

AL003 Evaporator Anti-freeze Manual

AL004 Compressor 1 circuit breaker Manual

AL005 System Flow Meter Manual

AL006 From digital input, EEV Auto

AL007 Pressure Switch high pressure Manual (password)

AL008 Transducer High pressure Manual

AL009 Pressure Switch low pressure Manual (password)

AL010 Transducer low pressure Manual

AL011 Critical low pressure Manual

AL012 Fan/condenser pump circuit breaker Manual

AL013 System pump 1 circuit breaker Manual

AL014 System pump 2 circuit breaker Manual

AL015 System pump 1 maintenance Auto

AL016 System pump 2 maintenance Auto

AL017 Compressor 1 Maintenance Auto

AL018 Compressor 2 Maintenance Auto

AL019 Probe U1 broken or disconnected Auto

AL020 Probe U2 broken or disconnected Auto

AL021 Probe U3 broken or disconnected Auto

AL022 Probe U4 broken or disconnected Auto

AL023 Probe U5 broken or disconnected Auto

AL024 Probe U6 broken or disconnected Auto

AL025 Probe U7 broken or disconnected Auto

AL026 Probe U8 broken or disconnected Auto

AL027 Probe U9 broken or disconnected Auto

AL028 Probe U10 broken or disconnected Auto

AL029 Turbocor1 Pressing line Gas High Temp. Manual

Loading...

Loading...