26

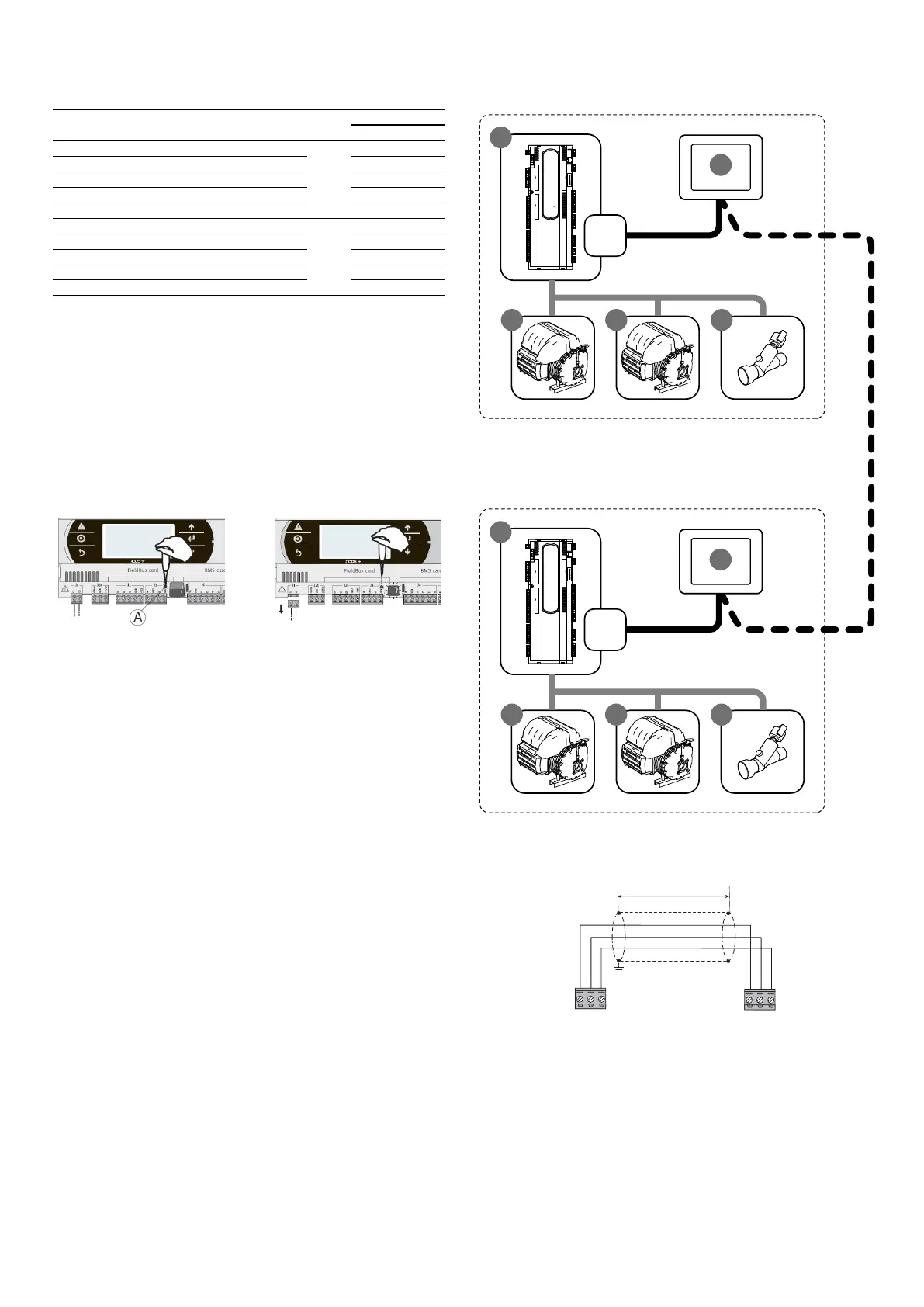

9.30 NOTES ON CONNECTING TWO MASTER/SLAVE UNITS

Table of contents Element Unit

Address

PLAN MODBUS

1 Display touch screen pGDTouch

Master

6

2 PCO5+ control board 1

3 EEV electronic valve driver 198

4 Driver turbocor 1 1

5 Driver turbocor 2 2

6 Display touch screen pGDTouch

Slave

7

7 PCO5+ control board 2

8 EEV electronic valve driver 198

9 Driver turbocor 1 1

10 Driver turbocor 2 2

The Master/Slave electrical connection of the two chillers is performed via a pLAN

line cable as shown in the gure (dotted line).

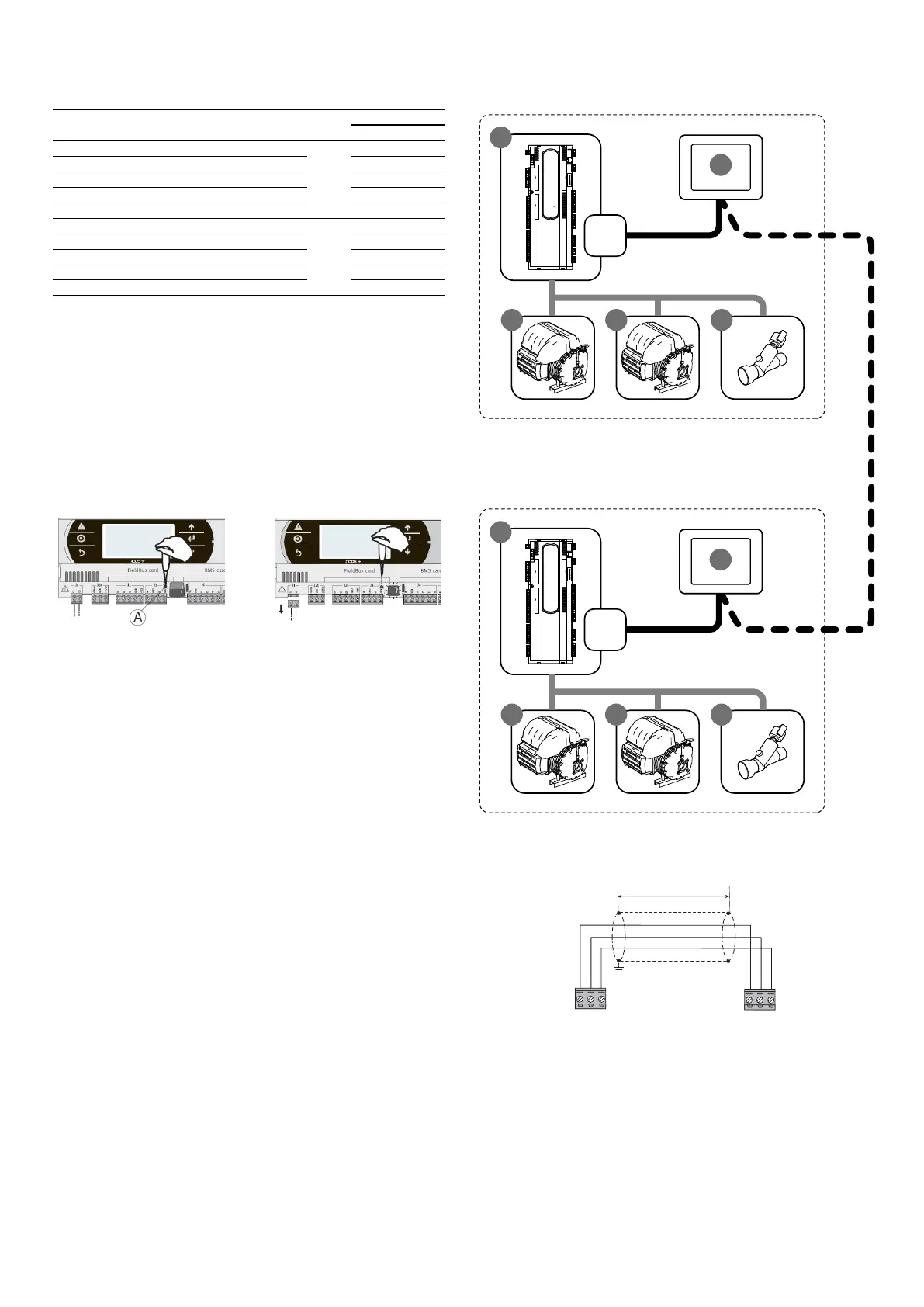

The pLAN address of the Master board must be set to 1 manually (default setting).

The pLAN address of the Slave board must be set to 2 manually, according to the

following procedure:

1. Using a suitable screwdriver, press the "A" key for 5 seconds. The pLAN address

will start to ash;

2. Repeatedly press the key until reaching the desired address and remove the

screwdriver;

3. Wait until the address starts ashing quickly, in this stage the address is stored

but not yet active for the application program;

4. Disconnect power from the control;

5. Return power to the control, now the address is active;

IMPORTANT 1: Provide the "evaporator common output probe" of the master and

place it in a point where the water temperature change is detected with only the

master on or with only the slave on. If a storage tank is present position it inside it.

IMPORTANT 2: In case of WMX/G and TW110 should you wish to change the mode

(COOLING/HEATING) it must be done both on the master and on the slave. The mas-

ter does NOT force change of the operating mode of the slave.

J11

J11

Plan

Modbus

Plan

Modbus

SLAVE unit

pLAN cable characteristics for MASTER/SLAVE connection:

Connect the screen to the ground

Loading...

Loading...