ines M192M / M191M / M245M / M234M / M282M / M281M

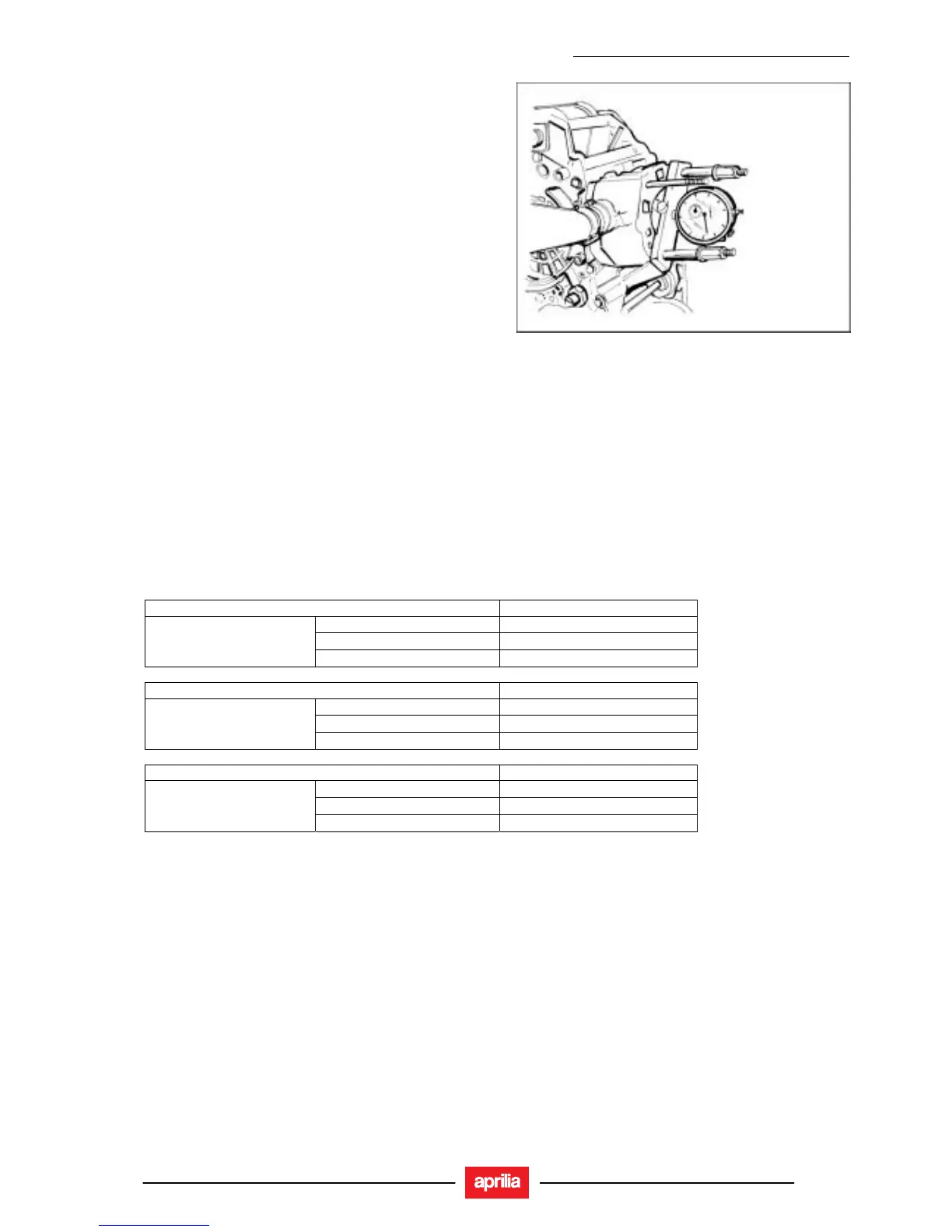

3.6.19. CHECKING PISTON POSITION

• Temporarily fit cylinder on piston, without bottom gas-

ket.

• Install a dial gauge on special tool.

Dial gauge holder: 8140266

• Reset dial gauge on a reference surface. With dial

gauge set at zero, fit tool on cylinder and lock it in

place with the four head fastening nuts.

• Turn camshaft to TDC (dial gauge will reverse direction

of rotation).

• Position dial gauge on piston as shown in the figure

and measure piston drawback.

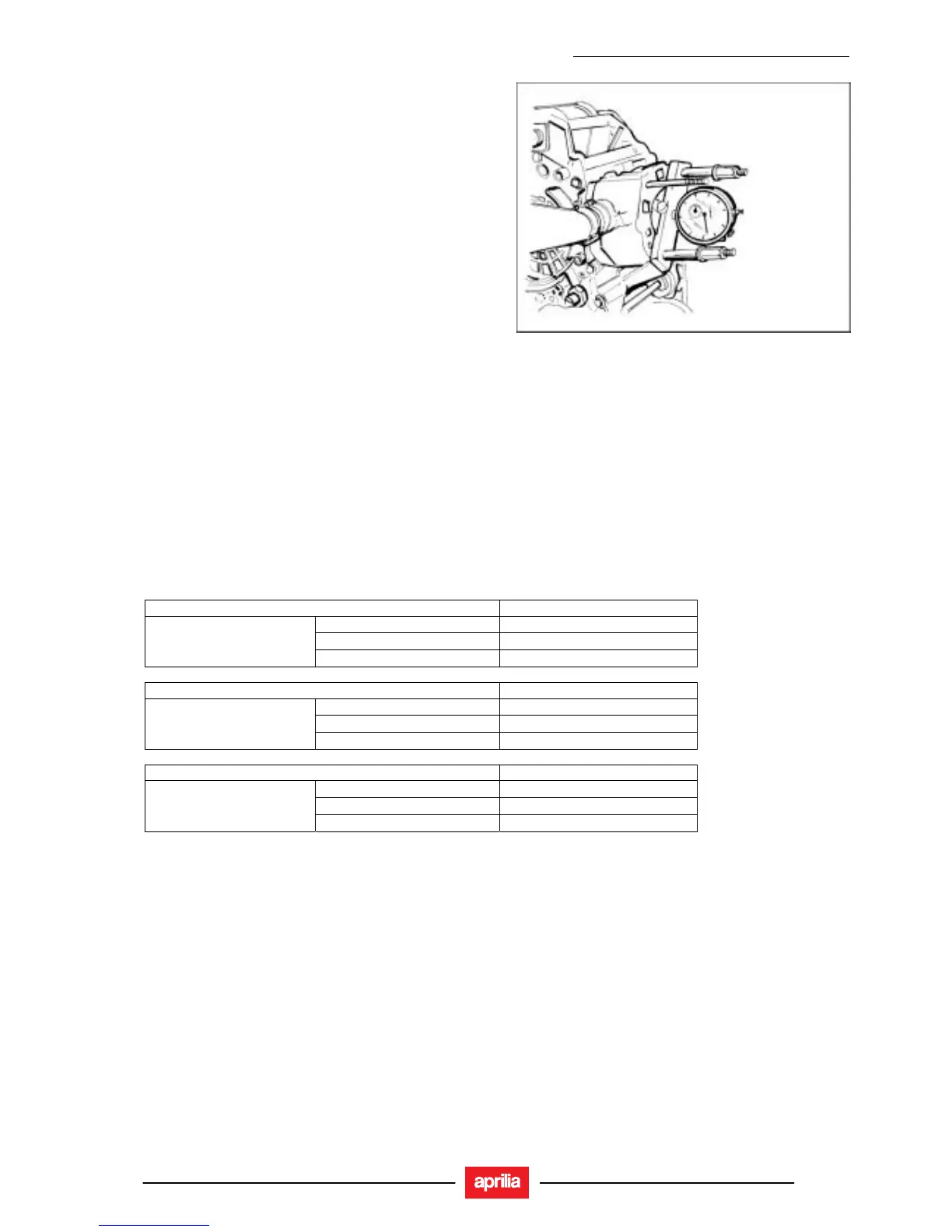

• Use the table below to determine the thickness of the

cylinder bottom gasket to be used at reassembly and

thus ensure the correct compression.

• Remove special tool and cylinder.

Note: The standout is measured on the 125 cc engine, the

drawback on the 200 cc engine.

Measured standout Gasket thickness

2.25 ÷ 2.35 mm 0.4 ± 0.05 mm

2.35 ÷ 2.55 mm 0.6 ± 0.05 mm

Engines M192M / M245M /

M281M (125 cc)

2.55 ÷ 2.65 mm 0.8 ± 0.05 mm

Measured standout Gasket thickness

1.0 ÷ 1.1 mm 0.8 ± 0.05 mm

1.1 ÷ 1.3 mm 0.6 ± 0.05 mm

Engine M191M (150 cc)

1.3 ÷ 1.4 mm 0.4 ± 0.05 mm

Measured standout Gasket thickness

0.9 ÷ 1.0 mm 0.8 ± 0.05 mm

1.0 ÷ 1.2 mm 0.6 ± 0.05 mm

Engines M234M / M282M

(200 cc)

1.2 ÷ 1.3 mm 0.4 ± 0.05 mm

Loading...

Loading...