ines M192M / M191M / M245M / M234M / M282M / M281M

3.2.7. INSTALLING THE FLYWHEEL

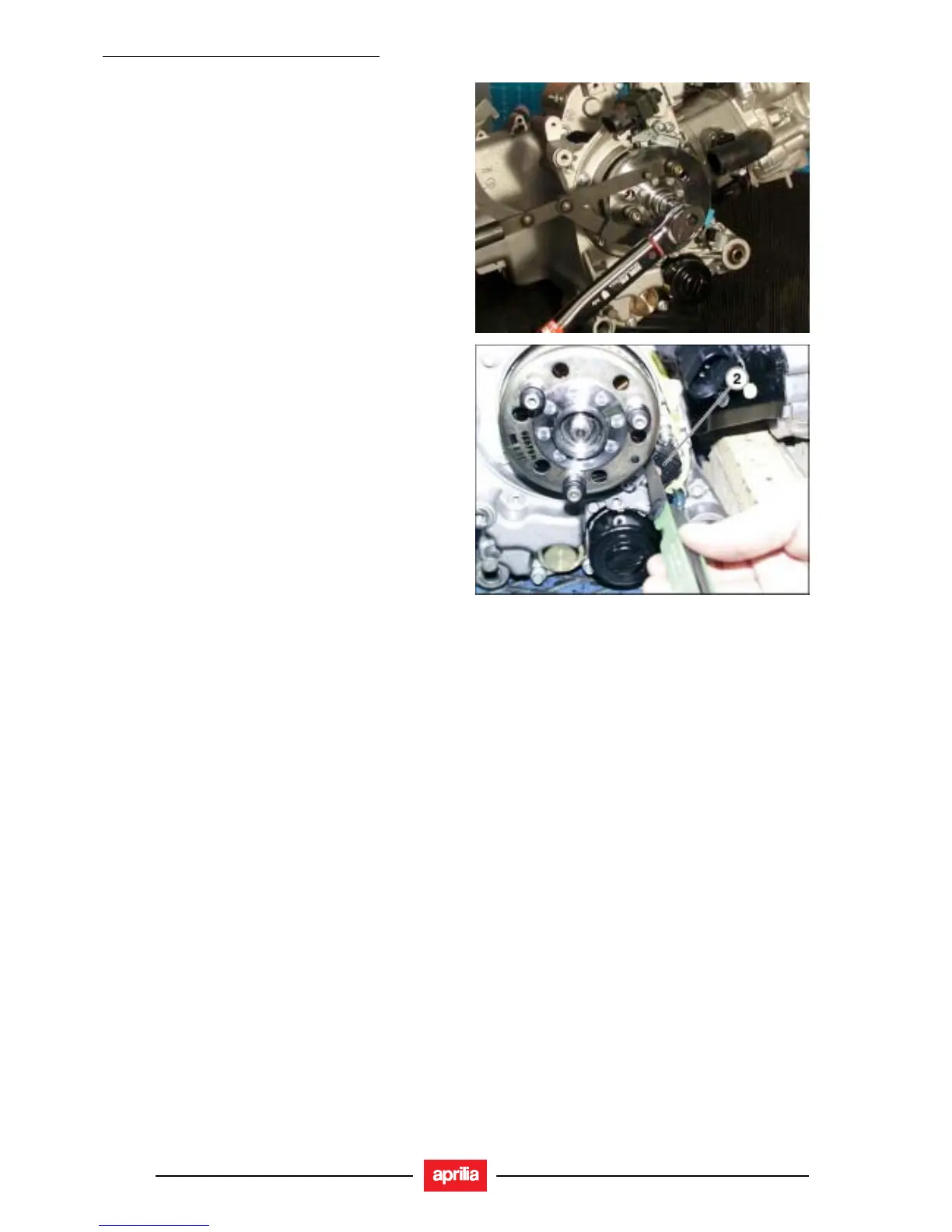

• Install the flywheel; ensure that the key is properly po-

sitioned.

• Tighten the flywheel nut to the specified torque; lock

the flywheel with the special tool:

Driving pulley lock wrench (Engines M191M / M234M /

M282M (150 - 200 cc) (adjustable face wrench) (A):

8106702

Driving pulley lock wrench (Engines M192M / M245M /

M281M) (125 cc): 8140535.

TIGHTENING TORQUE SETTINGS

Engines M192M / M245M / M281M / M191M (125 - 150 cc)

= flywheel nut: 52 ÷ 58Nm (5.2 ÷ 5.8 kgm)

Engines M234M / M282M (200 cc) = flywheel nut: 54 ÷

60Nm (5.4 ÷ 6.0 kgm)

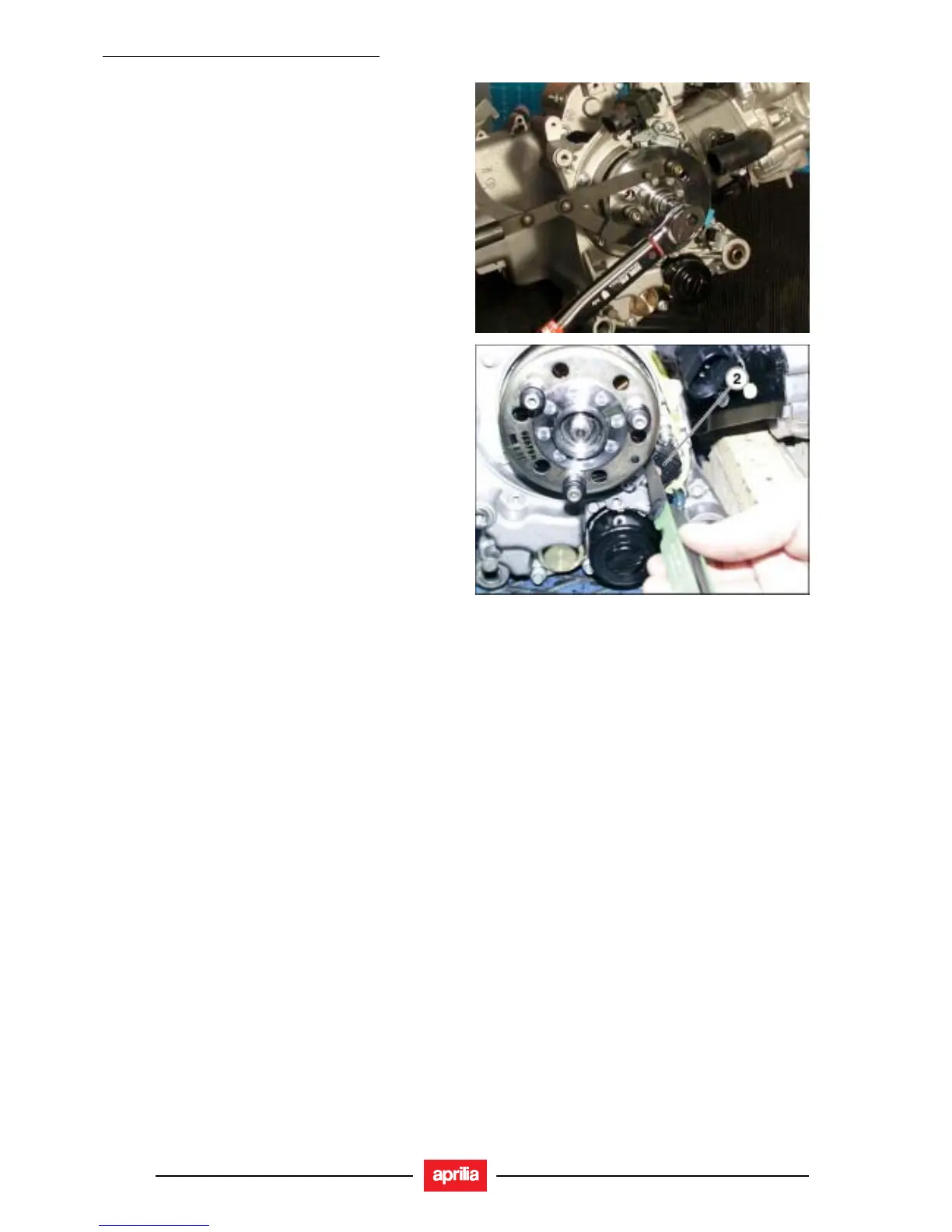

• Check that Pick-Up air gap is between 0.34 and 0.76

mm. The air gap is not adjusted when the Pick-Up is

installed. A warped Pick-Up support will change the air

gap value.

NOTE A variation in the air gap will alter the ignition slow-

running speed.

Loading...

Loading...