Robert Bosch GmbH

en 7

ACS 500

1 689 975 197 (2006-09-22)

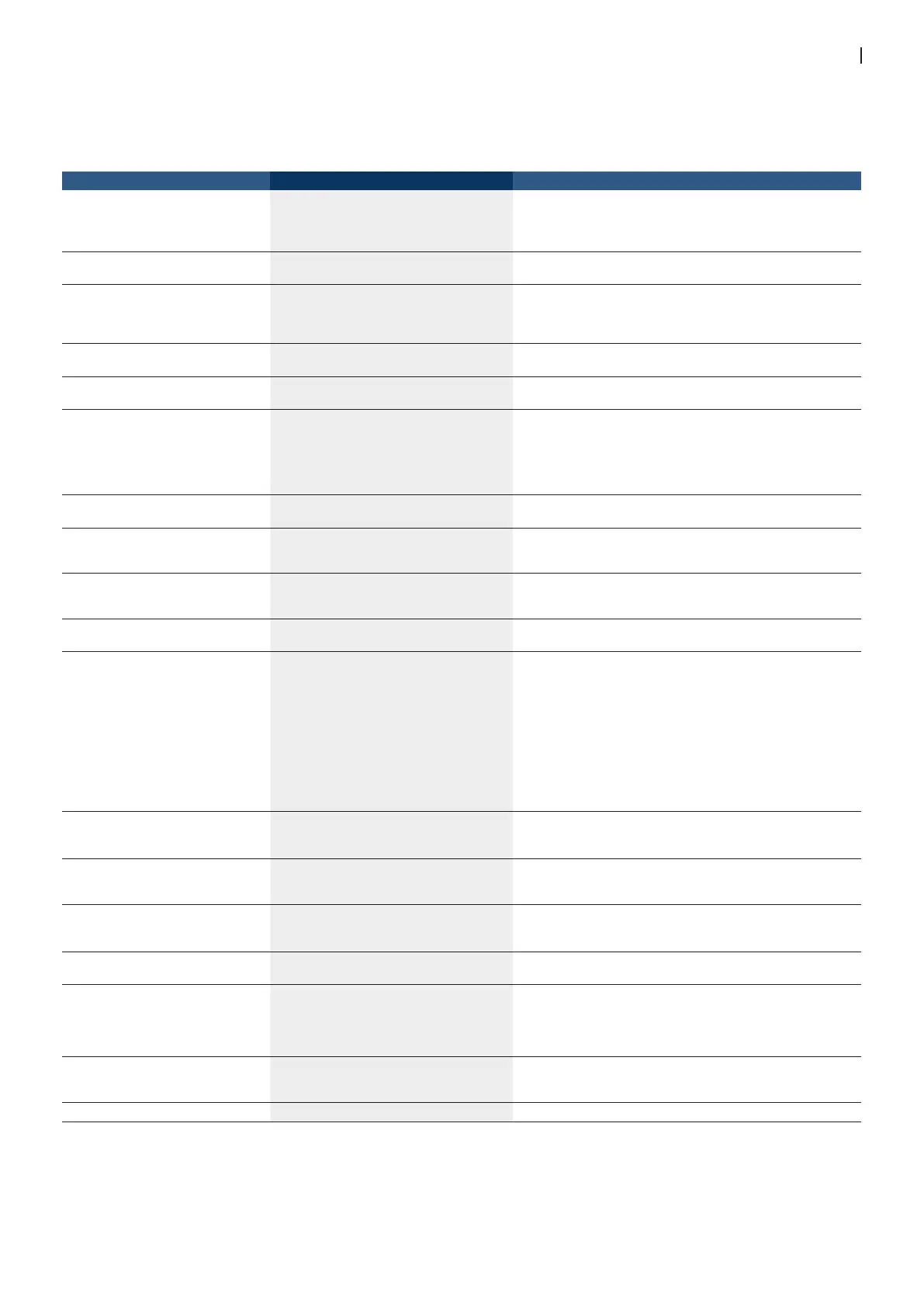

4. Troubleshooting

4.1 By function and fault messages

Message Description Problem solving

Change filter.

Change vacuum pump.

Maintenance interval reached. Carry

out maintenance and reset counter (see

Operating instructions 1 689 979 953,

Section 7).

None

Not enough R134a.

Please refill.

Insufficient refrigerant in internal refri-

gerant flask.

Top up refrigerant flask.

Control/display unit is defective. Replace control/display unit.

•

•

Used oil bottle full!

Empty used oil tank.

Force sensor for used oil scale is defective. Replace

force sensor.

Control/display unit is defective. Replace control/display unit.

•

•

•

Not enough oil.

Please refill.

Top up oil tank.•

Not enough UV.

Please refill.

Top up UV tank.•

Internal pressure too high! Overpressure in refrigerant flask.

Overpressure in path after compressor.

Open shut-off valves and cocks on internal refrigerant flask.

Turn off ACS 500 and wait for 30 minutes. Then restart

the recovery/recycling phase.

Check non-return valve in inlet hose for internal refrige-

rant flask.

Check pressure switch.

•

•

•

•

Printer failure! No paper loaded.

Printer defective.

Load new printer paper roll.

Replace printer.

•

•

Internal tank full. Maximum permissible filling weight (10

kg) of refrigerant flask reached.

Reduce quantity of refrigerant in refrigerant flask.

Check refrigerant scale with calibrating weight. Recali-

brate scale.

•

•

Warning! Internal tank full. Refrigerant flask weight limit reached.

Reduce quantity of refrigerant in refrigerant flask.

Check refrigerant scale with calibrating weight. Recali-

brate scale.

•

•

A/C system on

high pressure.

Absolute pressure in vehicle A/C system

is greater than 1.6 bar

Start and carry out recovery/recycling phase

Recovery phase timeout. Maximum permissible time (240 min)

for evacuation of vehicle A/C system re-

ached.

Read pressure on manometer.

Pressure is present:

Solenoid valves for recovery/recycling phase do not

open:

Check solenoid valves.

Check solenoid valve actuation.

No pressure present:

Vehicle A/C system not tight

or

leak in processing unit

Scan connections for leakage.

Check solenoid valve for oil drain.

•

$

$

•

$

$

A/C system leaking! Pressure increase during pressure loss

measurement (leak test) in vacuum pha-

se.

Check vehicle A/C system for leaks.

Check connections and condition of filling hoses.

Check connections and condition of quick release couplings.

•

•

•

Vacuum failure. Limit value of 100 mbar not reached

10 minutes after start of vacuum phase.

Check vehicle A/C system for leaks.

Check connections and condition of filling hoses.

Check connections and condition of quick release couplings.

•

•

•

Vacuum not reached! The pressure in the vehicle A/C system

is too high for oil or UV contrast medi-

um injection.

Start vacuum phase.

Check vehicle A/C system for leaks.

•

•

Calibration fault! Error in calibration of scale or scale de-

fective.

Recalibrate scale.

Replace scale.

•

•

External tank empty or closed val-

ve!

Attempt to fill internal flask failed.

Use full external flask.

Open low pressure (LP) and high pressure (HP) valve

Open valve cocks on refrigerant flask.

Check fill quantity in refrigerant flask and top up if neces-

sary.

•

•

•

•

Refill phase timeout. Maximum permissible time for filling the

vehicle A/C system reached.

Open low pressure (LP) and high pressure (HP) valve

Open valve cocks on refrigerant flask.

Check fill quantity in refrigerant flask and top up if necessary.

•

•

•

External tank empty! External flask for filling is empty.

Obtain new flask with refrigerant.•

Loading...

Loading...