1 689 979 672 2012-06-26| Robert Bosch GmbH

42 | EPS 807 / 815 | Maintenanceen

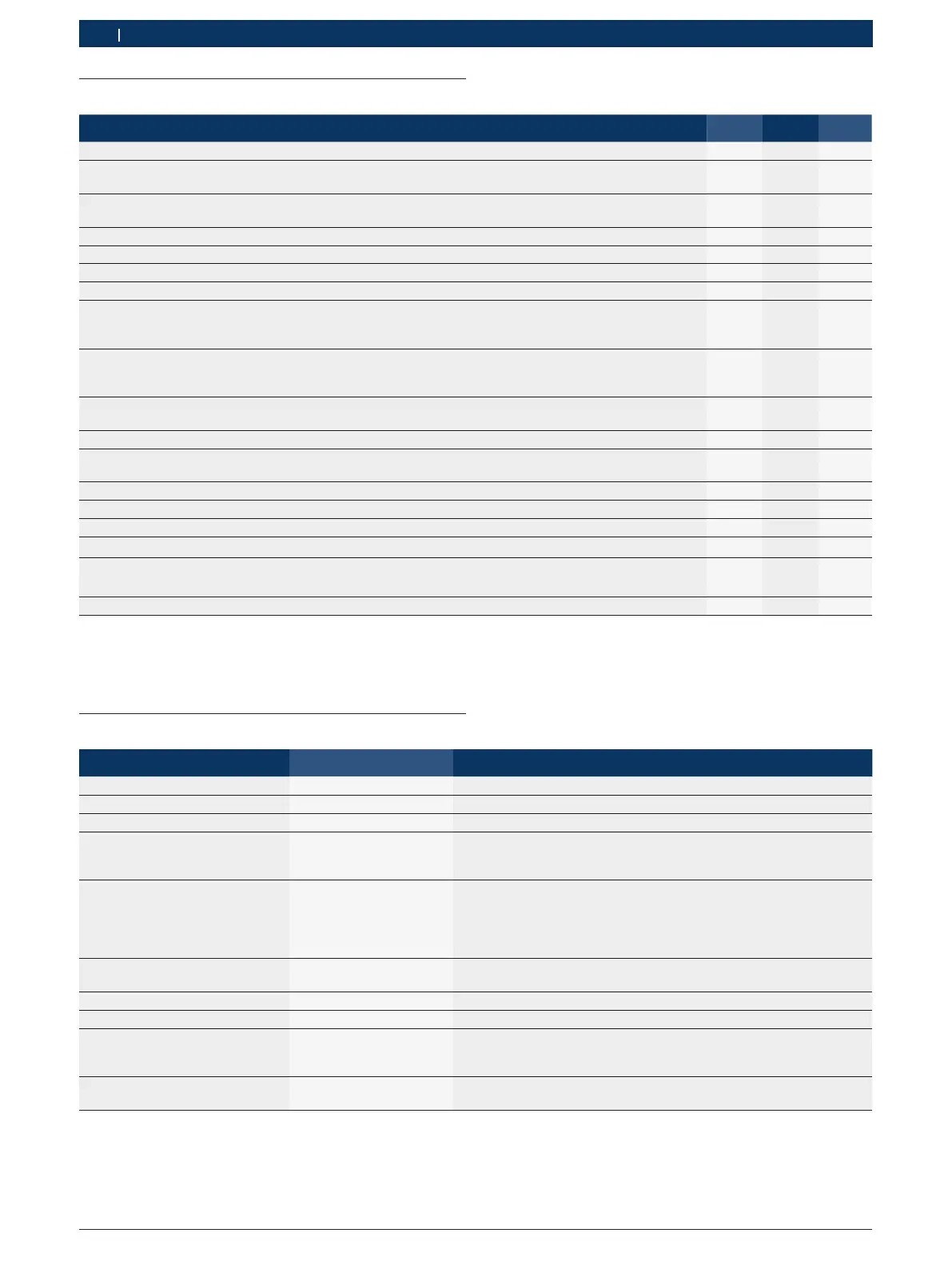

6.� Maintenance intervals

Maintenance work 1

*)

2

*)

�

*)

Check and, if required, adjust the nozzle opening pressure pursuant to the regulations. X X

Pressure lines: check that sealing cones and bores are in perfect condition;

if required replace with new pressure lines.

X

Interchange the nozzle holders and pressure lines and compare the flow rates.

The flow rates must be identical.

X

Replace pressure joint with rod filter or sieve filter. X

Measuring glasses: visual check; replace if required. X

Check measuring device (KMA802) for any leakages, and if found, rectify them. X

Check measuring accuracy of measuring device (KMA802). X

Measuring cells (KMA802): Perform flow measurement on even and odd ducts in succession and com-

pare the delivery rates with each other:

The same delivery rates must be measured.

X

Exchange the banjo bolt with the copper gaskets.

(Oil the copper gaskets! Tightening torque 30 + 3 Nm).(Outlet damping unit on KMAand KMM

60S3/80S3 and upgrade kits).

X

Check pressure gauge with calibrated pressure gauge.

Replace if deviations occur.

X X

Check accuracy of the temperature unit, measuring and control devices.Repair if deviations occur. X X

Check the stroke and rev counter for accuracy.

Repair if deviations occur.

X

Change the calibration fluid. X X

Replace the calibration-fluid filter.n. X X

Clean and rinse the calibration-fluid tank and suction filter. X X

Drain the contaminated oil in the storage area under the mounting rail. X X

Replace the lubricating oil filter in the lubricating oil supply pipe (optional accessory). X X

Change the lubricating oil X

Clean the lubricating oil tank. X

*)

Maintenance intervals

1 Weekly

2 After testing 200 injection pumps, at the latest after 2 months

3 During a main inspection or, if required, during the test service

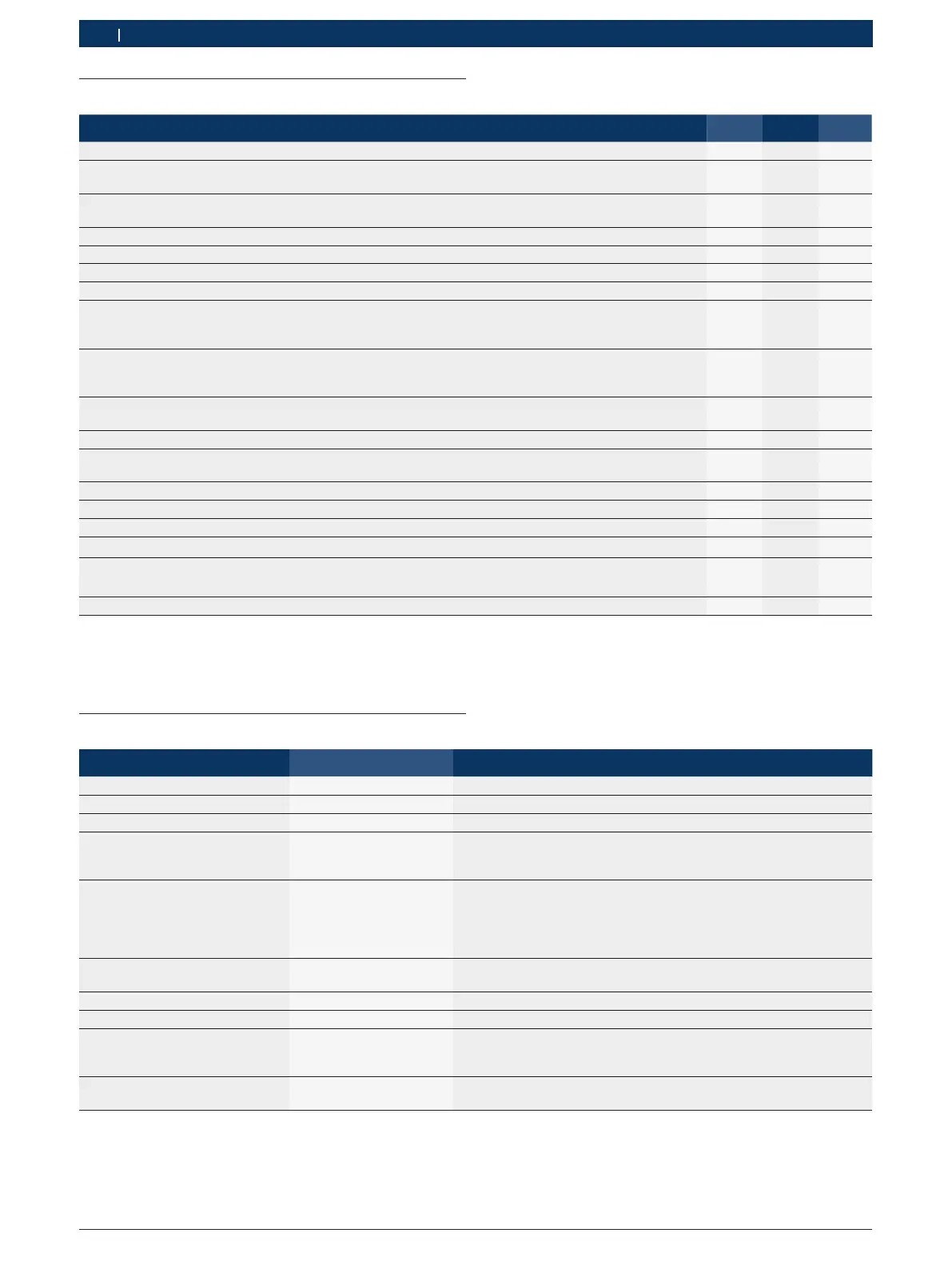

6.4 Spare parts and wearing parts

Designation Order no. Use

Fuel filter box < 1 687 434 028 For calibration fluid

Hydraulic inlet filter < 1 687 430 004 In the calibration-fluid tank

Lubricating oil filter < 1 687 434 061 For Lubricating oil supply

Hosepipe <

Hosepipe <

Hosepipe <

1 680 712 151

1 680 712 051

1 680 711 035

For calibration fluid (supply)

For calibration fluid (reflow)

Hosepipe for accessory set 1687010126

Shutoff valve

Temperature sensor, short

Temperature sensor, long

Connecting cable

Connecting cable

1 687 415 056

1 687 224 953

1 687 224 952

1 684 465 363

1 684 448 290

For testing distributor pump

For testing distributor pump

For tank temperature

For temperature sensor

For testing solenoid valve

Drive coupling

Tensioning bolt

1 686 401 026

2 910 406 358

For EPS807/815

M 12 x 80 with strength 12.9

Box spanner 1 687 950 058 A/F 11

T-bar 1 683 000 000 For flywheel

Hexagon spanner

Hexagon spanner

Hexagon spanner

1 907 950 007

1 907 950 008

1 907 950 009

A/F 6 for hexagon socket

A/F 8 for hexagon socket

A/F 10 for hexagon socket

Fuse links <

Fuse links <

1 904 522 347

1 904 522 343

5 AT 250 V

2 AT 250 V

Loading...

Loading...