1 695 600 091 2012-11-16| Robert Bosch GmbH

Auto-diagnosis menu | WBE 4200 | 47 en

¶ If the wheel does not turn listen if, by activating the

cycle, a "click" from the relays is emitted from the

power board.

7.3.1 Check belt tensioning

To check the tensioning of the transmission belt, use

the tensiometer for optibelt TT mini S belts (nominal

value: 110 ±10 Hz).

7.4 0_10 (Analogical)

i

Page for the monitor of analog entries.

From this menu you can directly read the signal that

comes from the sensors (pick-ups and potentiometers).

This means that you can identify the cause of the

defect.

Here you have a summary of the functions:

Left Display Right Display Description

0 2050

Reading of the analog entry of

the external pick-up

1 2050

Reading of the analog entry of

the internal pick-up

2 2050

Reading of the analog entry of

the external enlarged pick-up

3 2050

Reading of the analog entry of

the enlarged internal pick-up

4 200

Reading of the sensor of the

distance

5 200

Reading of the sensor of the

width

6 200

Reading of the sensor of the

diameter

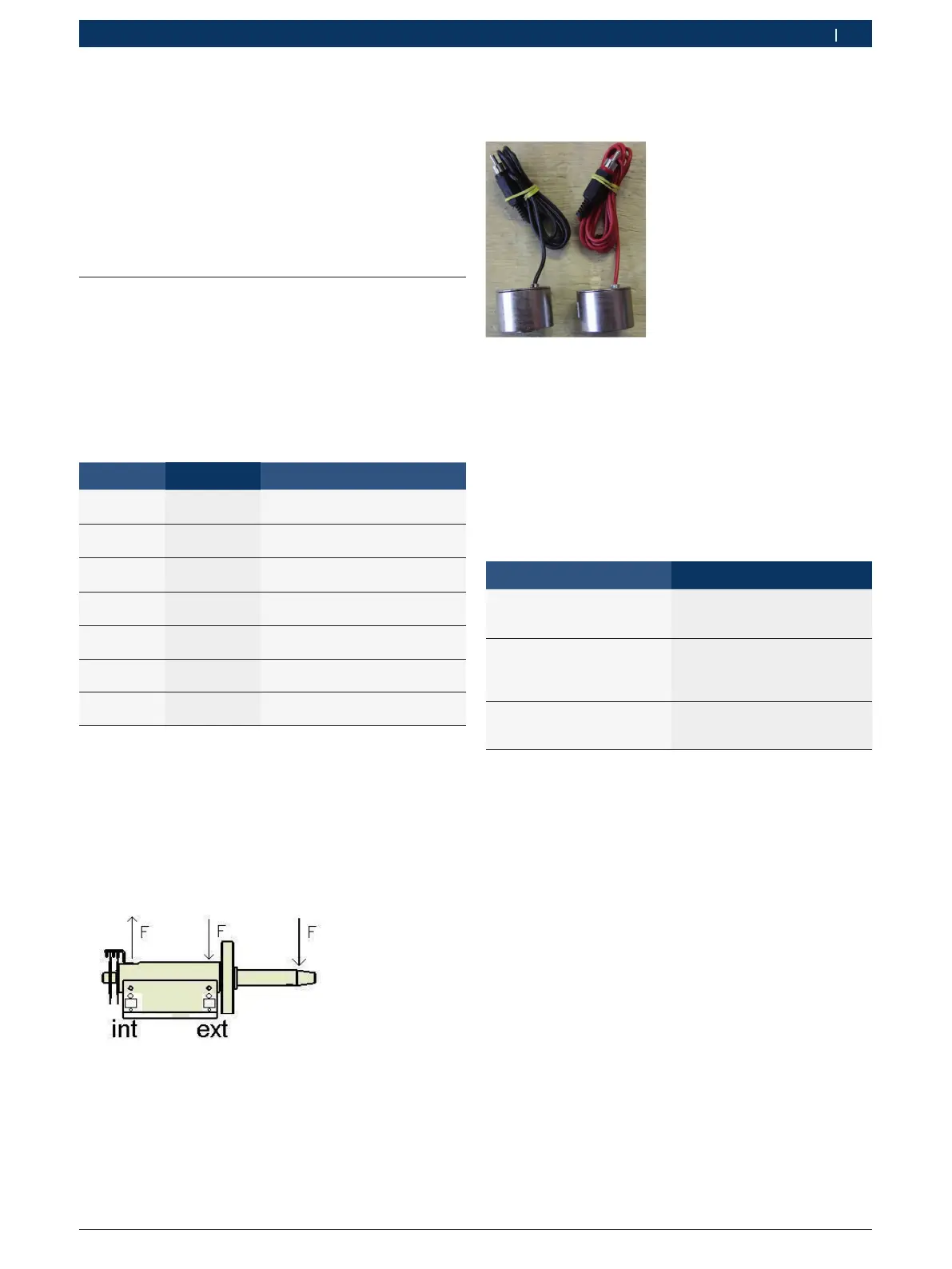

7.4.1 0 - Signal of the external pick-up.

The piezoelectric sensor reads a strength variation.

During the checking phase, verify that:

R the value of rest is in the middle of the reading scale;

R if you push the shaft down, the value increases up to

the end of the scale;

R if you lift the shaft up, the value decreases to zero.

7.4.2 1 - Signal of the internal pick-up.

Now the sensor is mounted in the other position.

During the checking phase, verify that:

R the value of rest is in the middle of the reading scale;

R if you push the shaft down, the value decreases to

zero;

R if you lift the shaft up, the value increases up to the

end of the scale.

Fig. 9: Sensor

NOTES OR THE ASSISTANCE:

The sensors (code 654432) are identical and in order to

distinguish them during the production, they mount the

red pick-up outside and the black one inside.

Here you can find some examples and possible

solutions:

Defect Correction

One of the pick-ups reached

the saturation point: the

tension is 0 or 4095.

R Substitute the board.

R Substitute the pick-up.

You can see the difference

between the rest values: ex.

Internal 2050 (from 2000 to

2100 OK) - External 1900.

R Reposition the pick-ups.

R Substitute the pick-up (in

our case the external one).

The machine often needs to

be set.

R Reposition the pick-ups.

R Substitute both the pick-

ups.

i To replace the pick-ups, see chap. 9.5 .

7.4.3 2 e 3

These values always refer to the tension detected by

the pick-ups, but in this case it is enlarged and filtered

by the board.

During the checking phase we don’t care about these

electric signals because they are just necessary to

calculate the unbalance.

7.4.4 4 - Signal of the potentiometer of the distance

i The potentiometer that we use is a multiturn

potentiometer which means that the shaft must

make more than a single turn to go to the other side

of the stroke.

NOTES OR THE ASSISTANCE:

Loading...

Loading...