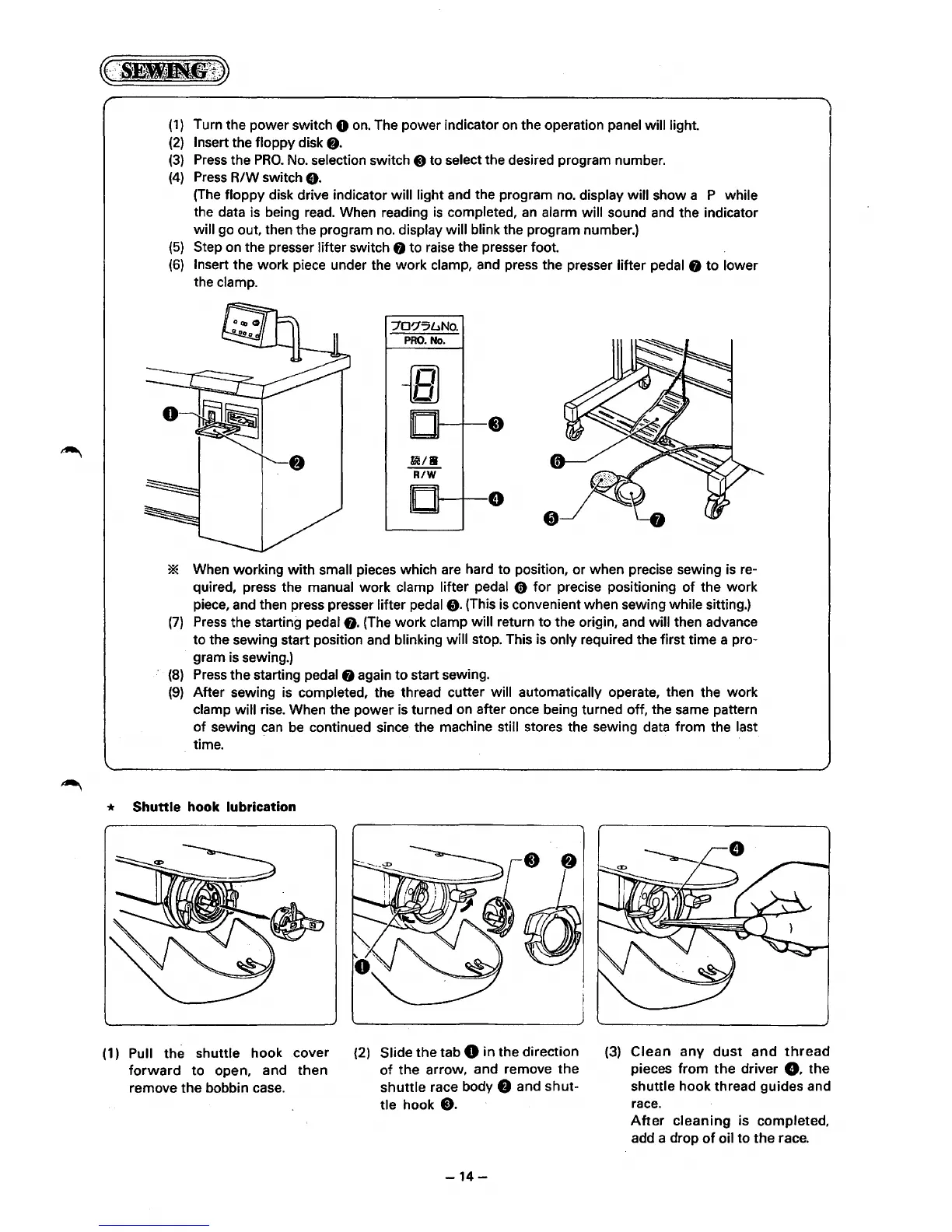

(1)

Turn the power switch 0

on.

The power indicator

on

the operation panel will light.

(2)

Insert the floppy disk

o.

(3)

Press

the

PRO.

No.

selection switch

@)

to select the desired program number.

(4)

Press

R/W switch

o.

(The

floppy disk drive indicator will light

and

the program

no.

display will show a P while

the data

is

being

read.

When reading

is

completed,

an

alarm will sound

and

the indicator

will go out, then the program

no.

display will blink the program number.)

(5)

Step on the presser lifter switch

f)

to

raise

the presser foot.

(6)

Insert the work piece under the work clamp, and press the presser lifter pedal

f)

to lower

the clamp.

7D'75l..1No.

PRO.

No.

-a

,

I

IC/8

R/W

0

e

* When working with small pieces which

are

hard to position, or when precise sewing

is

re-

quired, press the manual work clamp

lifter pedal 0 for precise positioning

of

the work

piece, and then press presser lifter pedal

f).

(This

is

convenient when sewing while sitting.)

(7)

Press

the starting pedal

f).

(The work clamp will return to the origin, and will then advance

to the sewing start position and blinking

will stop. This is only required the first time a pro-

. gram

is

sewing.)

(8)

Press

the starting pedal

f)

again to start sewing.

(9)

After sewing

is

completed, the thread cutter will automatically operate, then the work

clamp

will

rise.

When the power is turned

on

after once being turned off, the same pattern

of

sewing

can

be

continued since the machine still stores the sewing data from the last

time.

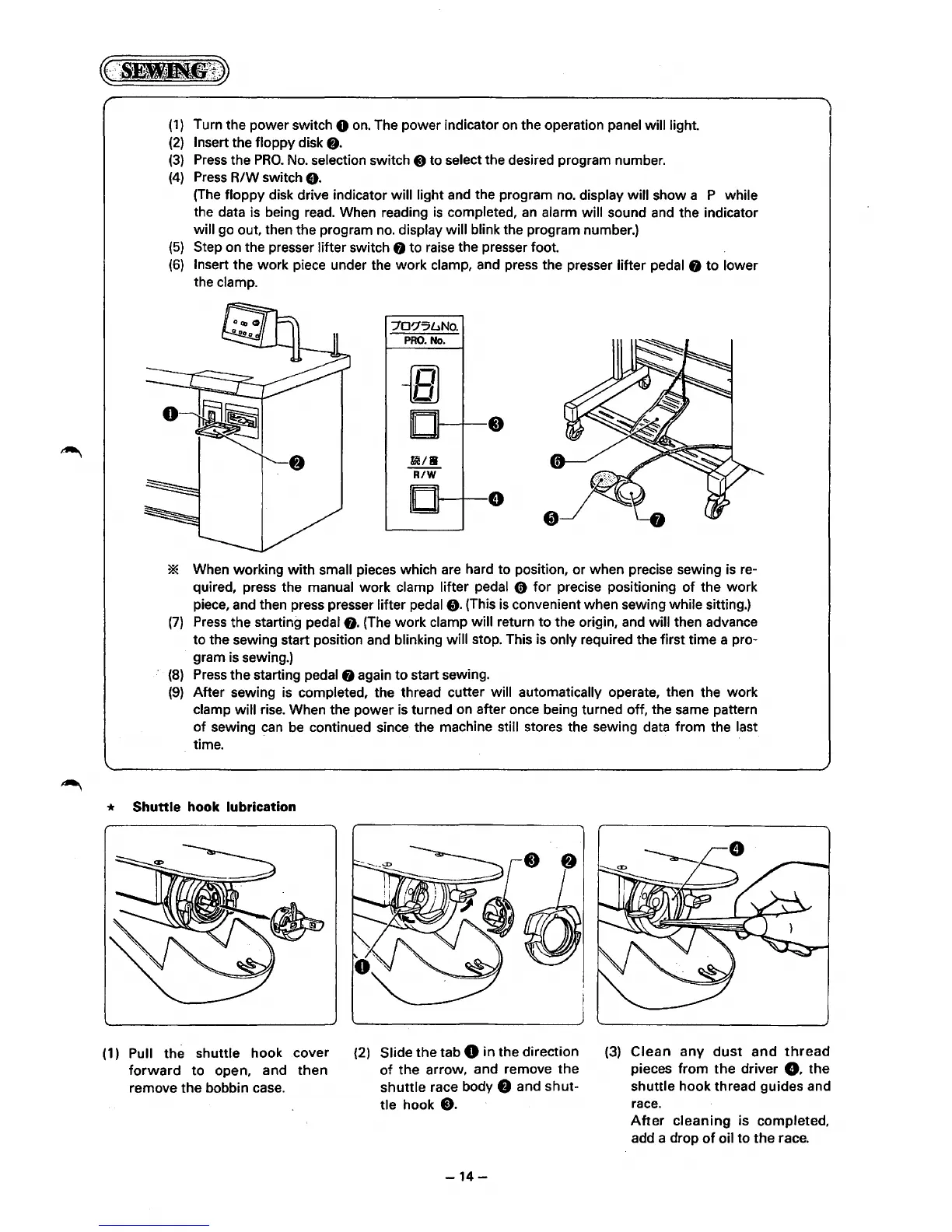

* Shuttle hook lubrication

(1)

Pull the shuttle hook cover

forward

to open, and then

remove the bobbin case.

(2)

Slide the tab 0 in the direction

of the arrow, and remove the

shuttle race body

8 and shut-

tle hook

e.

-14-

(3)

Clean

any

dust

and

thread

pieces from

the

driver

e.

the

shuttle hook thread guides and

race.

After

cleaning

is completed,

add a drop

of

oil to the race.

Loading...

Loading...