lm

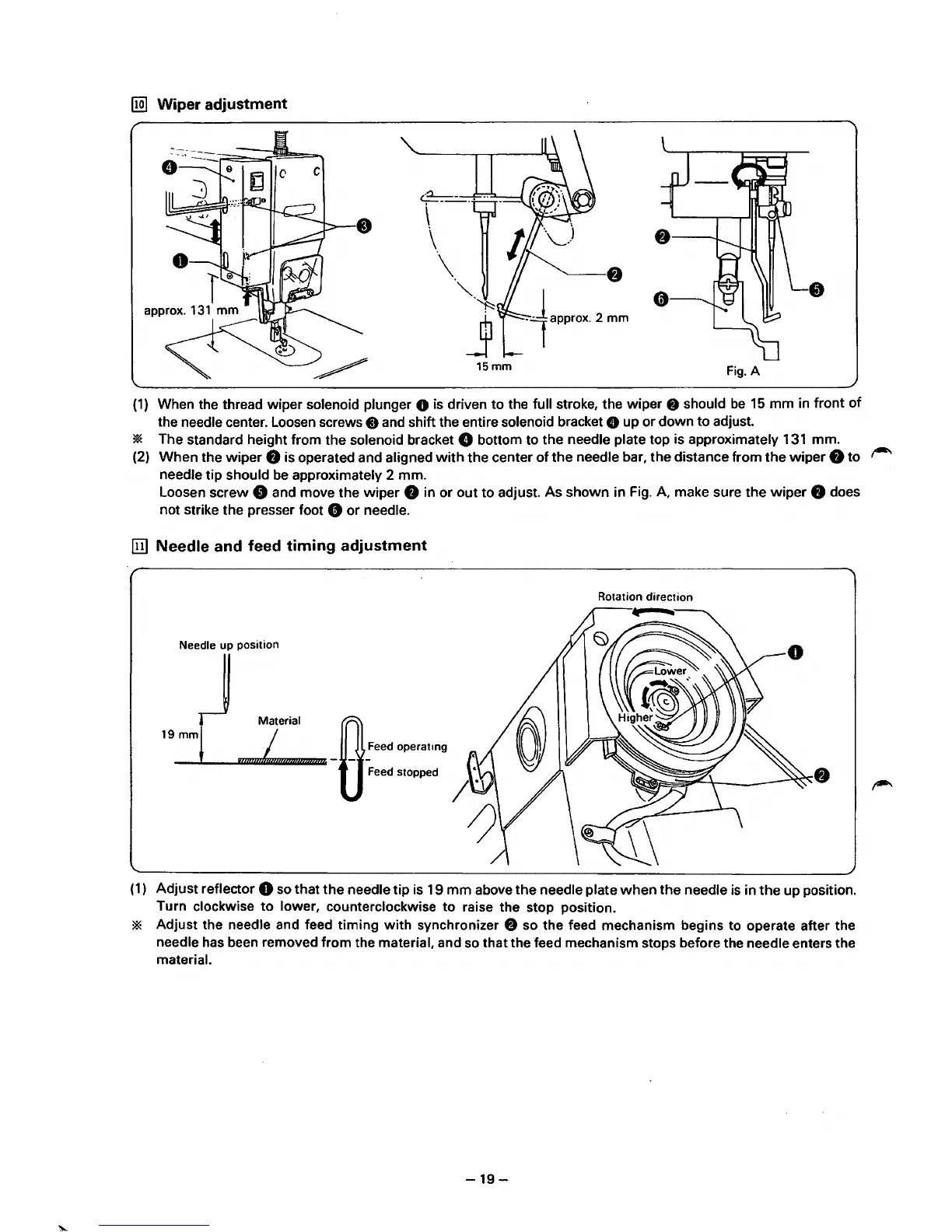

Wiper

adjustment

"---f)

-1

approx. 2 mm

15mm

Fig. A

(1)

When the thread wiper solenoid plunger 0

is

driven to the full stroke, the wiper 8 should

be

15

mm in front

of

the needle center. Loosen screws 0 and shift the entire solenoid bracket 0 up

or

down to adjust.

* The standard height from the solenoid bracket 8 bottom to the needle plate top is approximately 131 mm.

(2)

When

the

wiper

f)

is operated and aligned

with

the center of the needle bar, the distance from the

wiper

8 to ,.....

needle tip should

be

approximately 2 mm.

Loosen screw

8 and move the wiper 8 in

or

out to adjust. As shown in

Fig.

A,

make sure the

wiper

8 does

not strike the presser foot

8 or needle.

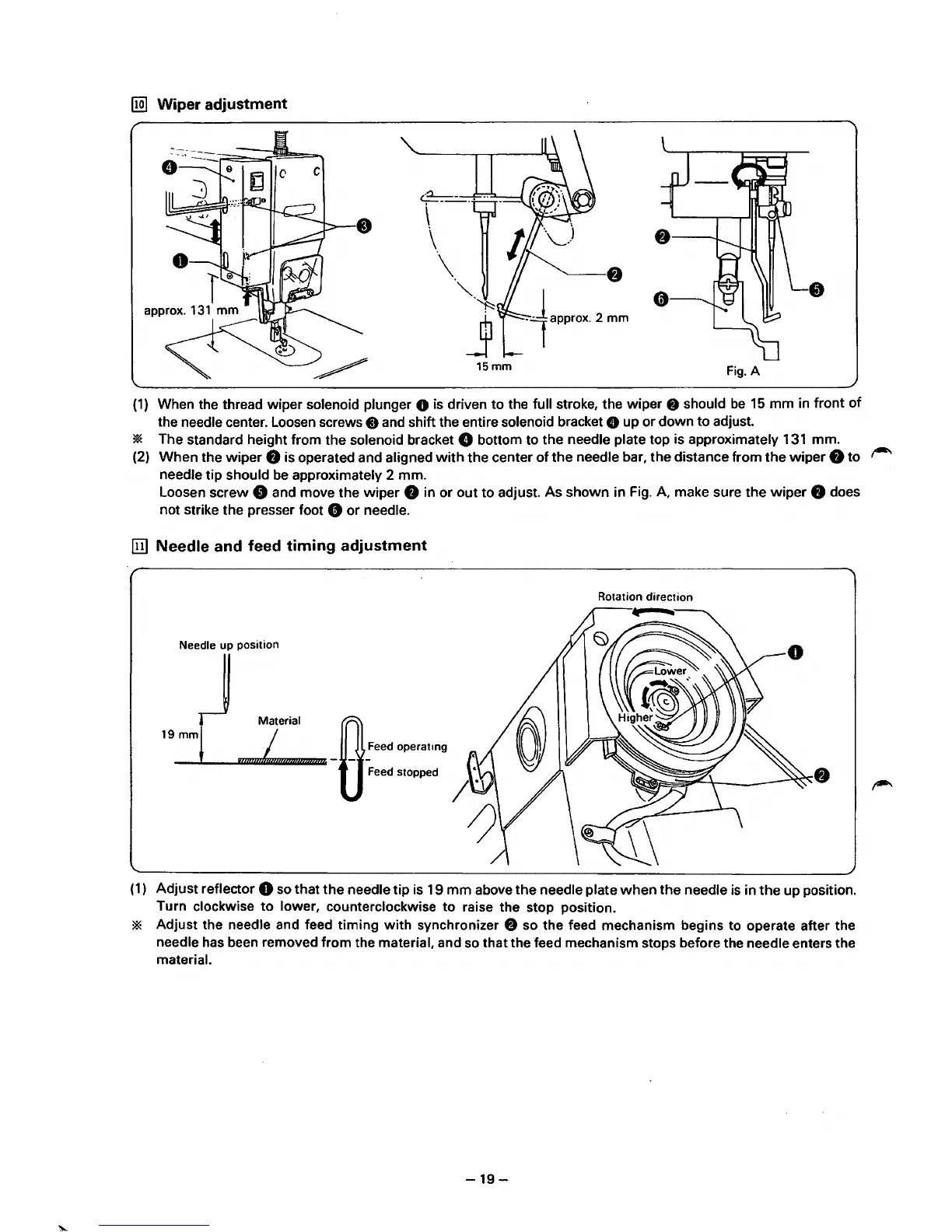

[TI]

Needle

and

feed

timing

adjustment

Needle up position

19 mm

Material B

-...L---I'llrlllllZlEi"lll'llZl2llllZIB _ _

~eed

operating

Feed stopped

I.,

•

1

(1)

Adjust reflector 0 so that

the

needle

tip

is

19

mm

above

the

needle plate

when

the needle

is

in

the

up position.

Turn clockwise to lower, counterclockwise

to

raise the stop position.

* Adjust the needle and feed timing with synchronizer 8 so the feed mechanism begins to operate after the

needle

has

been removed from the material, and so that the feed mechanism stops before the needle enters the

material.

-19-

Loading...

Loading...