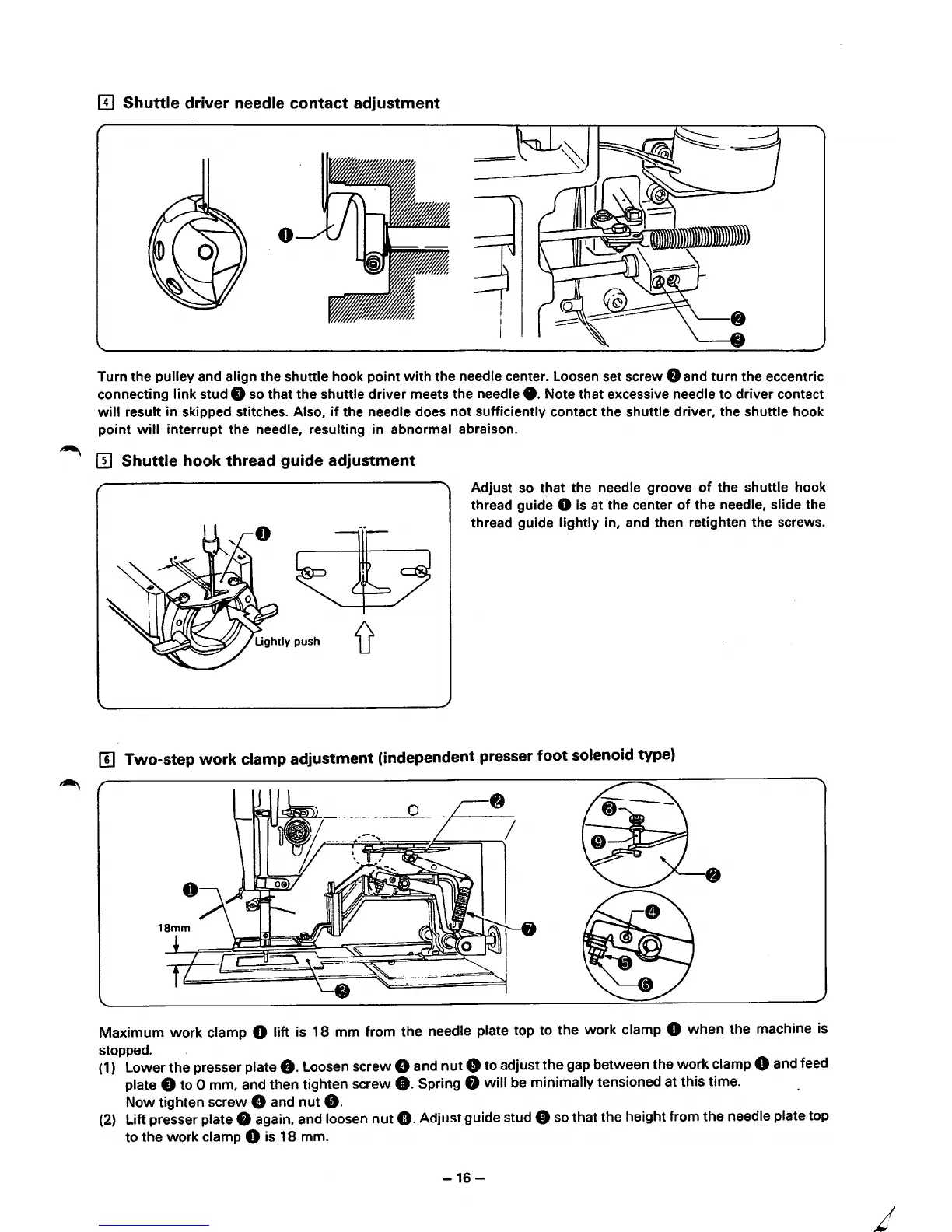

[I]

Shuttle

driver

needle

contact

adjustment

Turn the pulley and align the shuttle hook

point

with

the needle center. Loosen set screw 8 and

turn

the eccentric

connecting

link

stud 8 so that the shuttle

driver

meets the needle

0.

Note that excessive needle

to

driver

contact

will

result in skipped stitches. Also,

if

the needle does

not

sufficiently contact the shuttle driver, the shuttle hook

point

will

interrupt the needle, resulting in abnormal abraison.

~

[I]

Shuttle

hook

thread

guide

adjustment

Adjust so that the needle groove

of

the shuttle hook

thread guide

0 is at the center

of

the needle, slide the

thread guide

lightly

in, and then retighten the screws.

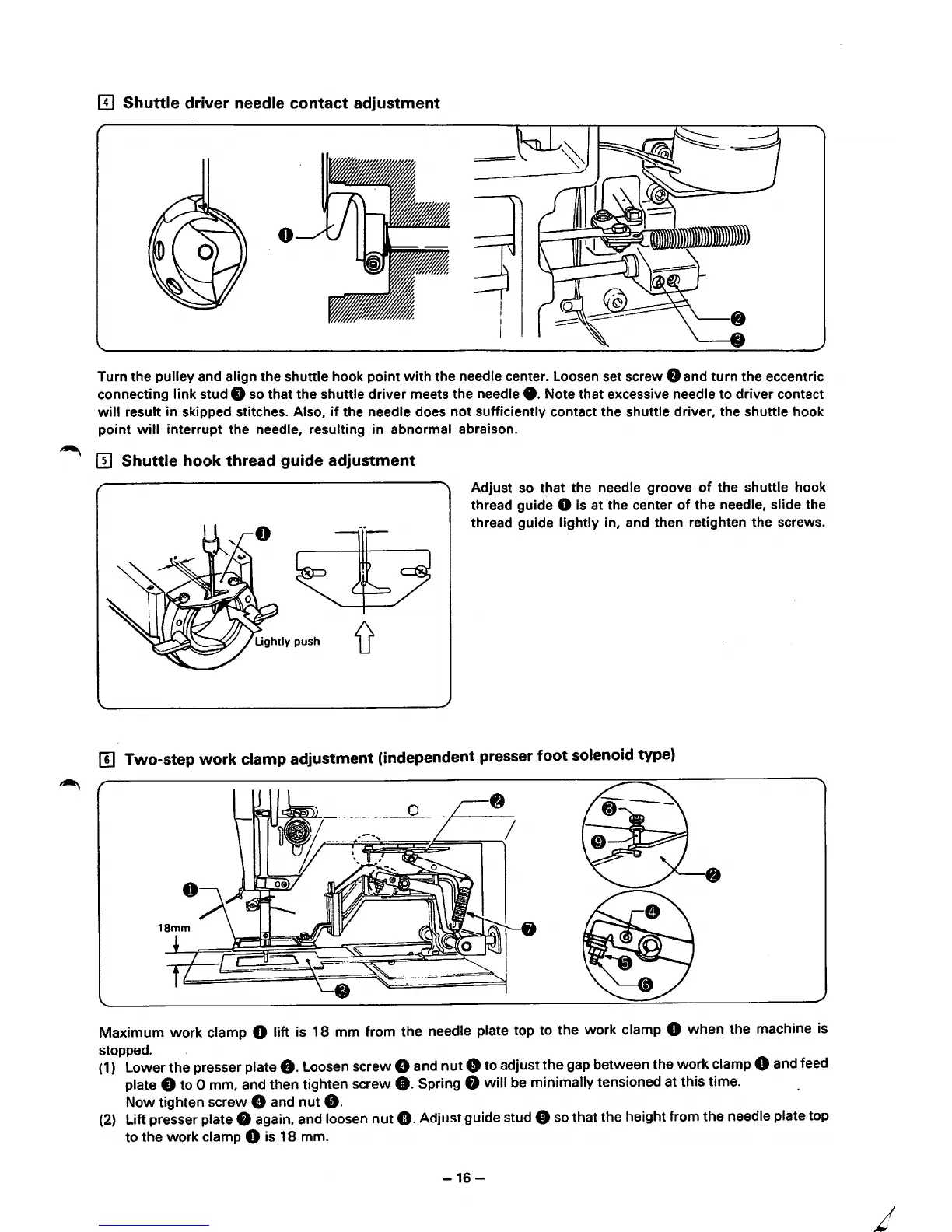

[!]

Two-step

work

clamp

adjustment

(independent presser

foot

solenoid type)

Maximum

work

clamp 0 lift is

18

mm

from

the

needle plate top to

the

work

clamp 0

when

the machine is

stopped.

(1)

Lower

the

presser plate

8.

Loosen screw 8 and

nut

8

to

adjust

the

gap between

the

work

clamp 0 and feed

plate

8 to 0 mm, and

then

tighten screw

8.

Spring 8

will

be

minimally

tensioned at

this

time.

Now

tighten

screw

8 and

nut

8.

(2) Lift presser plate 8 again, and loosen

nut

0.

Adjust

guide stud 8 so

that

the

height

from

the

needle plate top

to

the

work

clamp 0 is

18

mm.

-16-

Loading...

Loading...