11

Step 5 — Field Fabricate Ductwork

Cabinet return-air static pressure (a negative condition)

shall not exceed 0. 35 in. wg (87 Pa) with economizer or

0.45 in. wg (112 Pa) without economizer.

For vertical ducted applications, secure all ducts to roof curb

and building stru ctur e. Do not connect ductwork to unit.

Fabrica te supply ductwork so that the cross sectional

dimensions are equal to or greater than the unit supply

duct opening dimensions for the first 18 in. (458 mm) of

duct length from the unit basepan.

Insulate and weatherproof all external ductwork, joints,

and roof openings with counter flashing and mastic in

accordance with applicable codes.

Ducts passing through unconditioned spaces must be

insulated and covered with a vapor ba rrier.

If a plenum return is used on a vertical unit, the return

should be ducted through the roof deck t o comply with

applicable fire codes.

PROPER TY DAMAGE HAZARD

Failure to follow this caution may result in damage

to roofing materials.

Membrane roofs can be cut by sharp sheet metal

edges. Be careful when placing any sheet metal parts

on such roof.

CAUTION

!

For Units with Accessory Electric Heaters —

All installations require a minimum clearance to

combustible surfaces of 1 --in (25 mm) from duct for first

12--in (305 mm) away from unit.

Outlet grilles must not lie directly below unit discharge.

PERSONAL INJURY HAZARD

Failure to follow this warning could cause personal

injury.

For vertica l supply a nd return units, tools or parts

could drop into ductwork and cause an injury. Install

a 90--degree turn in the return ductwork between the

unit and the conditioned space. If a 90--degree e lbow

cannot be installed, then a grille of sufficient strength

and density should be installed to prevent objects

from falling into the conditioned space. Due to

electric heater, supply duc t will require 90--degree

elbow.

!

WARNING

C06005

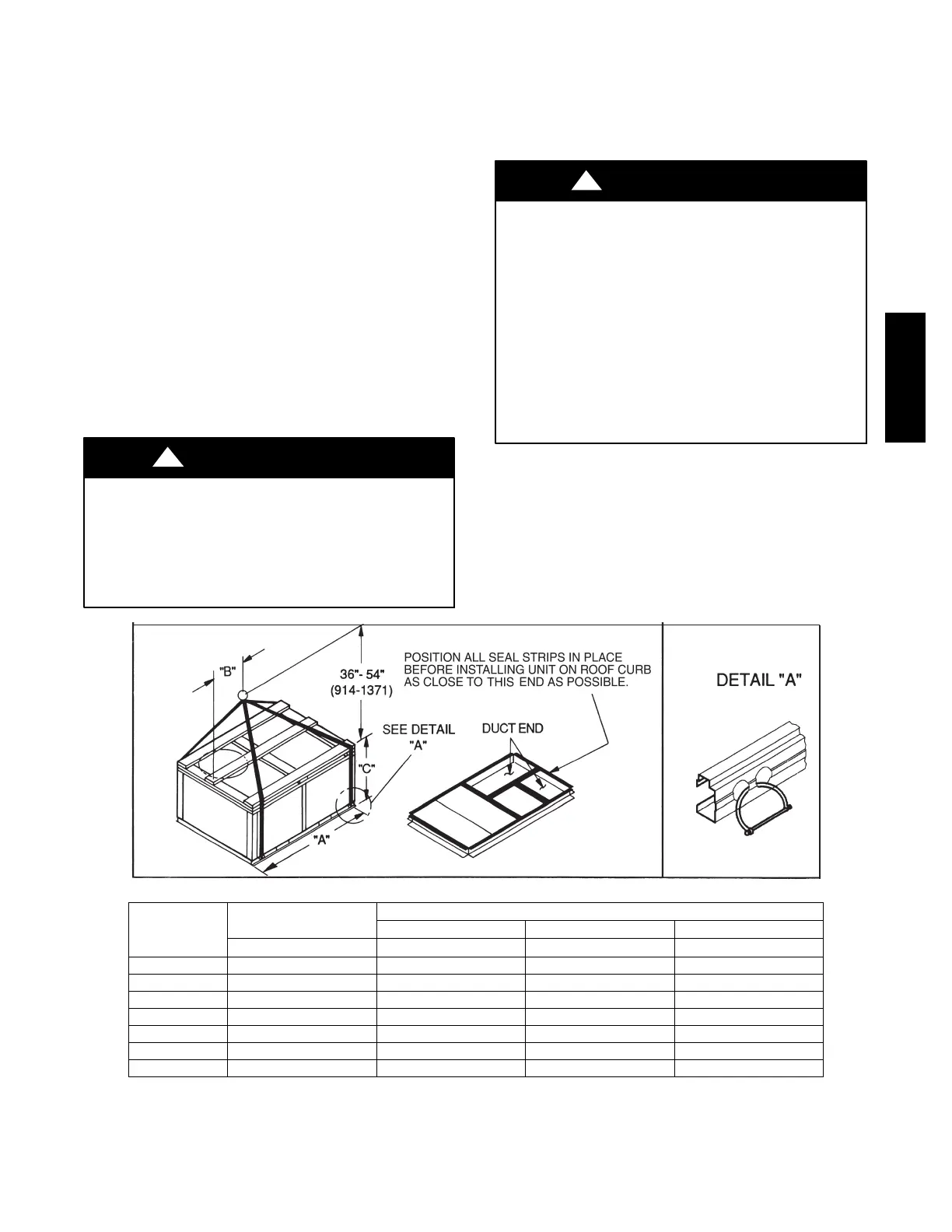

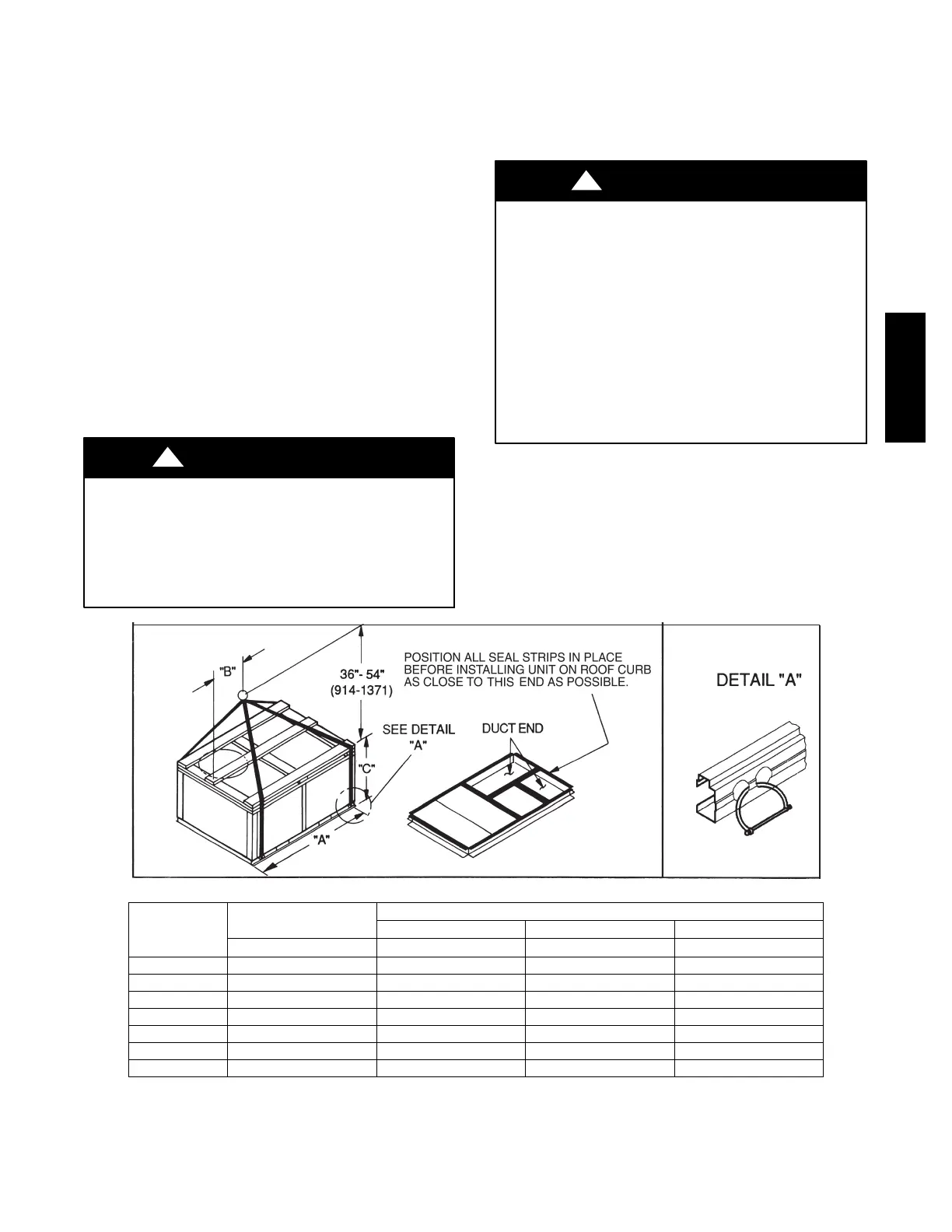

UNIT

MAX WEIGHT

DIMENSIONS

A B C

LB KG IN MM IN MM IN MM

50TC ---A08 1290 586 88.0 2235 40.0 1015 41.5 1055

50TC ---A09 1410 641 88.0 2235 39.5 1005 49.5 1255

50TC ---A12 1515 689 88.0 2235 41.0 1040 49.5 1255

50TC ---D/E08 1410 641 88.0 2235 41.0 1040 41.5 1055

50TC ---D/E09 1525 693 88.0 2235 40.5 1030 49.5 1255

50TC ---D/E12 1565 711 88.0 2235 40.0 1015 49.5 1255

50TC ---D/E14 1720 782 88.0 2235 28.5 725 53.0 1345

NOTES:

1. Dimensions in ( ) are in millimeters.

2. SPREADER BARS REQUIRED — Top damage will occur if spreader bars are not used.

3. Hook rigging shackles through holes in base rail, as shown in detail “A.” Holes in base rails are centered around the unit center of gravity .

Use wooden top to prevent rigging straps from damaging unit.

Fig. 7 -- Rigging Details

50TC

Loading...

Loading...