14

Step 9 — Install External Condensate Trap and

Line

The unit has one

3

/

4

-in. condensate drain connection on

the end of the condensate pan and an alternate connection

on the bottom. See Fig. 14. Unit airflow configuration

does not dete rmine which drain connection to use . Either

drain connection can be used with vertical or horizontal

applications.

To use the alternate bottom drain connection, remove the

red drain plug from the bottom connection (use a

1

/

2

-- i n .

square socket drive extension) and install it in the side

drain connection.

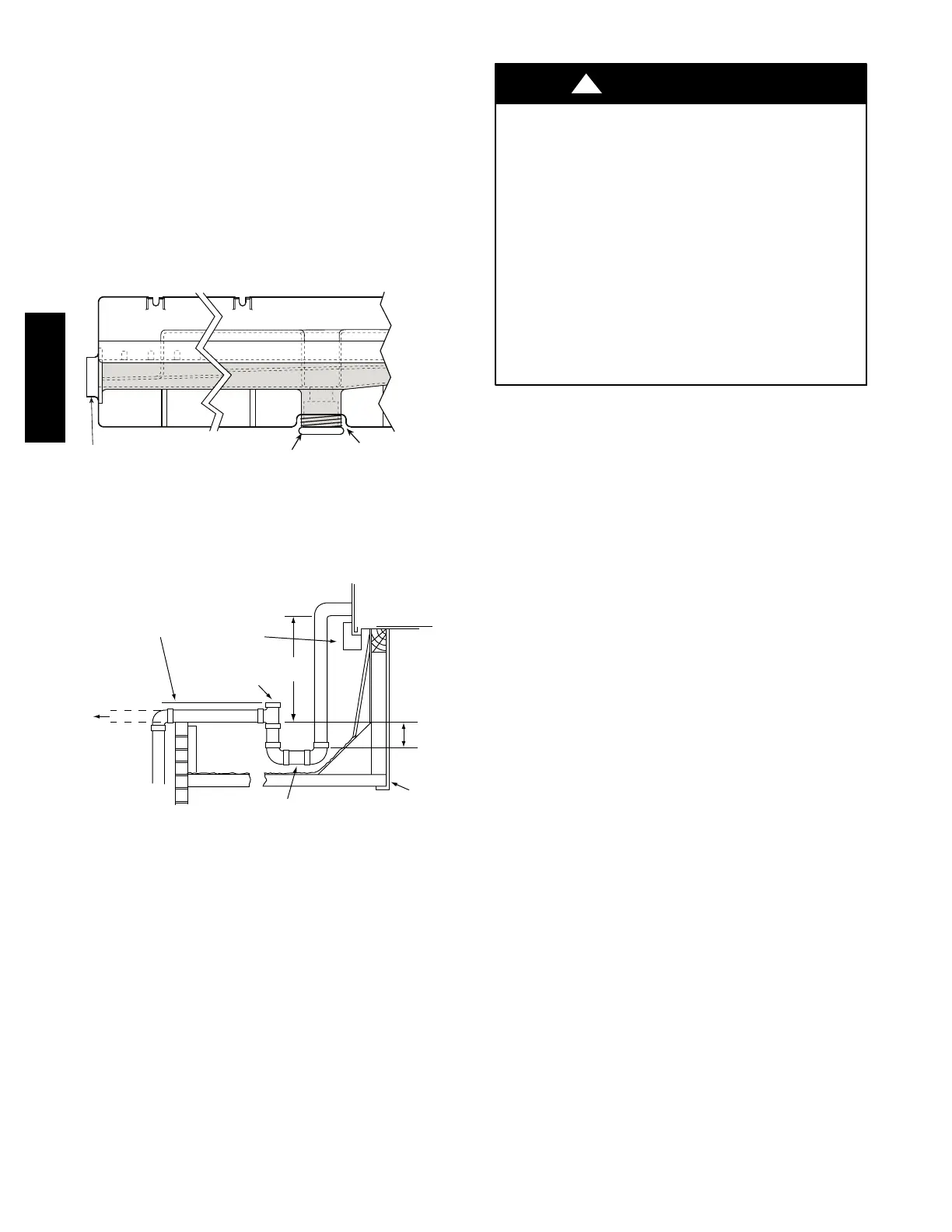

DRAIN

(FACTORY-INSTALLED)

PLUG

CONDENSATE PAN (SIDE VIEW)

STANDARD

SIDE DRAIN

ALTERNATE

BOTTOM DRAIN

C08021

Fig. 14 -- Condensate Drain Pan (Side View)

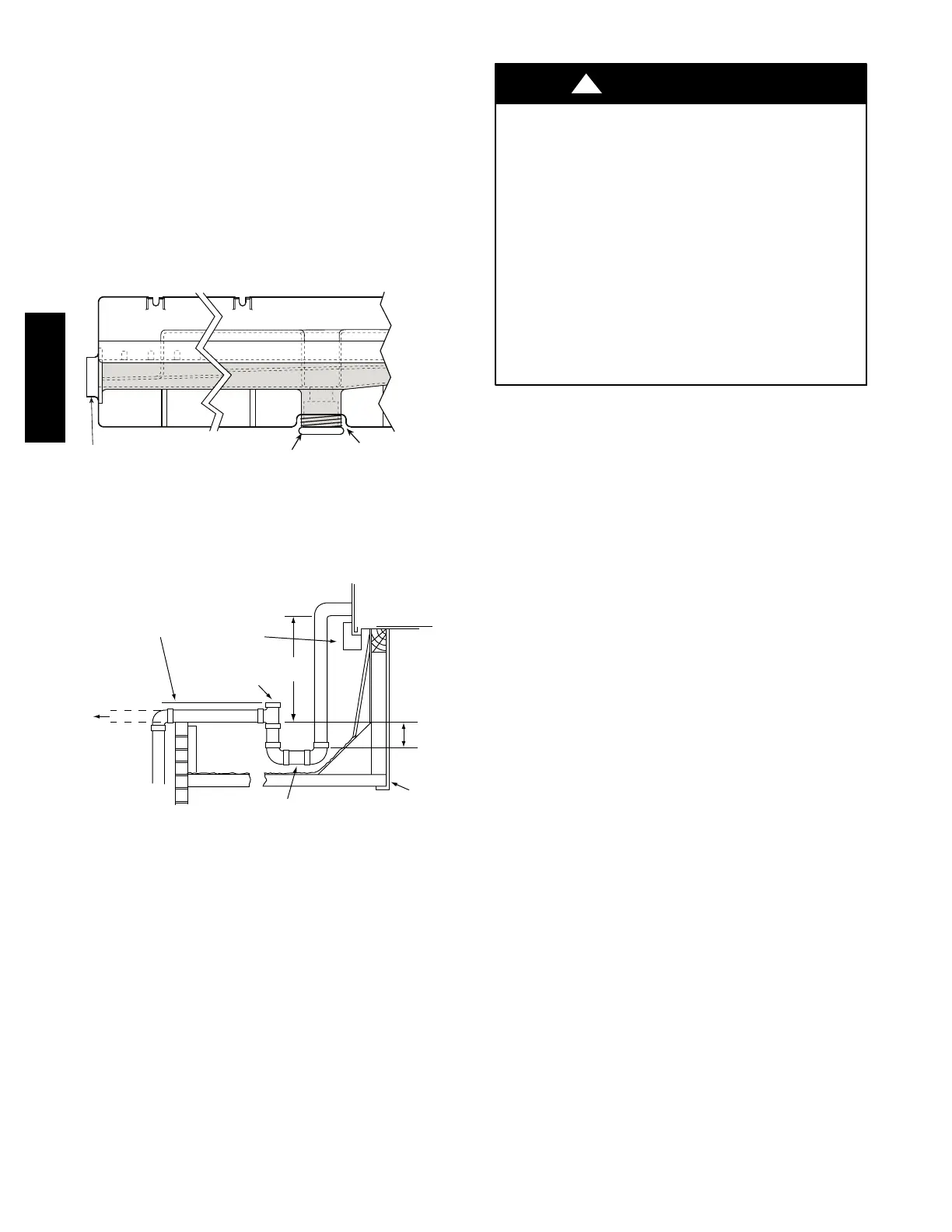

The piping for the condensate drain and e xternal trap can

be completed after the unit is in place. See Fig. 15.

NOTE: Trap should be deep enough to offset maximum unit static

difference. A 4” (102mm) trap is recommended.

MINIMUM PITCH

1” (25mm) PER

10’ (3m) OF LINE

BASE RAIL

OPEN

VENT

TO ROOF

DRAIN

DRAIN PLUG

ROOF

CURB

SEE NOTE

3˝ (76mm)

MIN

C11291

Fig. 15 -- Condensate Drain Piping Details

All units must have an external trap for condensate

drainage. Install a trap at least 4-in. (102 mm) deep and

protect against freeze-up. If drain line is installed

downstream from the external trap, pitch the line away fr om

the unit at 1-in. per 10 ft (25 mm in 3 m) of run. Do not use

a pipe size sma ller than the unit connection (

3

/

4

-in.).

Step 10 — Make Electrical Connections

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result i n personal

injury or death.

Do not use gas piping as an elec trical ground. Unit

cabi net must have an uninterrupted, unbroken

electrical ground to minimize the possibility of

personal injury if an electrica l fault should oc cur. This

ground may consist of electrical wire connected t o

unit ground lug in control compartment, or conduit

approved for e lectrical ground when install ed in

accordance with NEC (National Electrical Code);

ANSI/NFPA 70, latest edition (in Canada, Canadian

Electrical Code CSA [Canadian Standards

Association] C22.1), and local electrical codes.

!

WARNING

NOTE: Check all factory and field electrical connections

for tightness. Field--supplied wiring shall conform with

the limitations of 63_F(33_C) rise.

Field Power Supply —

If equipped with opti onal Powered Conve nience Outlet:

The power source leads to the convenience outlet’s

transformer pri mary are not factory connected. Installer

must connect these leads according to required operation

of the convenience outlet. If an always--energized

conveni ence outlet operation is desired, connect the

source lea ds to the l ine side of the unit--mounted

disconnec t. (Check with local codes to ensure this method

is acceptable in your area.) If a de--energize via unit

disconnec t switch operation of the convenience outlet is

desired, connect the source leads to the load side of the

unit disconne ct. On a unit without a unit--mounted

disconnec t, connect the source leads t o compressor

contactor C and indoor fan contactor IFC pressure lugs

with unit field power leads.

All units except 208/ 230-v units are factory wired for the

voltage shown on the nameplate. If the 208/230-v unit is

to be connected to a 208-v power supply, the control

transformer must be rewired by moving t he black wire

with the

1

/

4

-in. female spade connector from the 230--v

connec tion and moving it to the 208-v

1

/

4

-in. male

terminal on the primary side of the transformer. Refer to

unit label diagram for additional information. Fiel d power

wires will be connected line--side pressure lugs on the

power t erminal block or at fact ory--install ed option

non--fused disconnect.

Field power wires are connected to the unit at line-- side

pressure lugs on c ompressor contactor C and indoor fan

contactor IFC (see wiring diagram label for control box

component arrangeme nt) or at fac tory--installed option

non--fused disconnect switch. Max wire size is #4 AWG

(copper only).

50TC

Loading...

Loading...