12

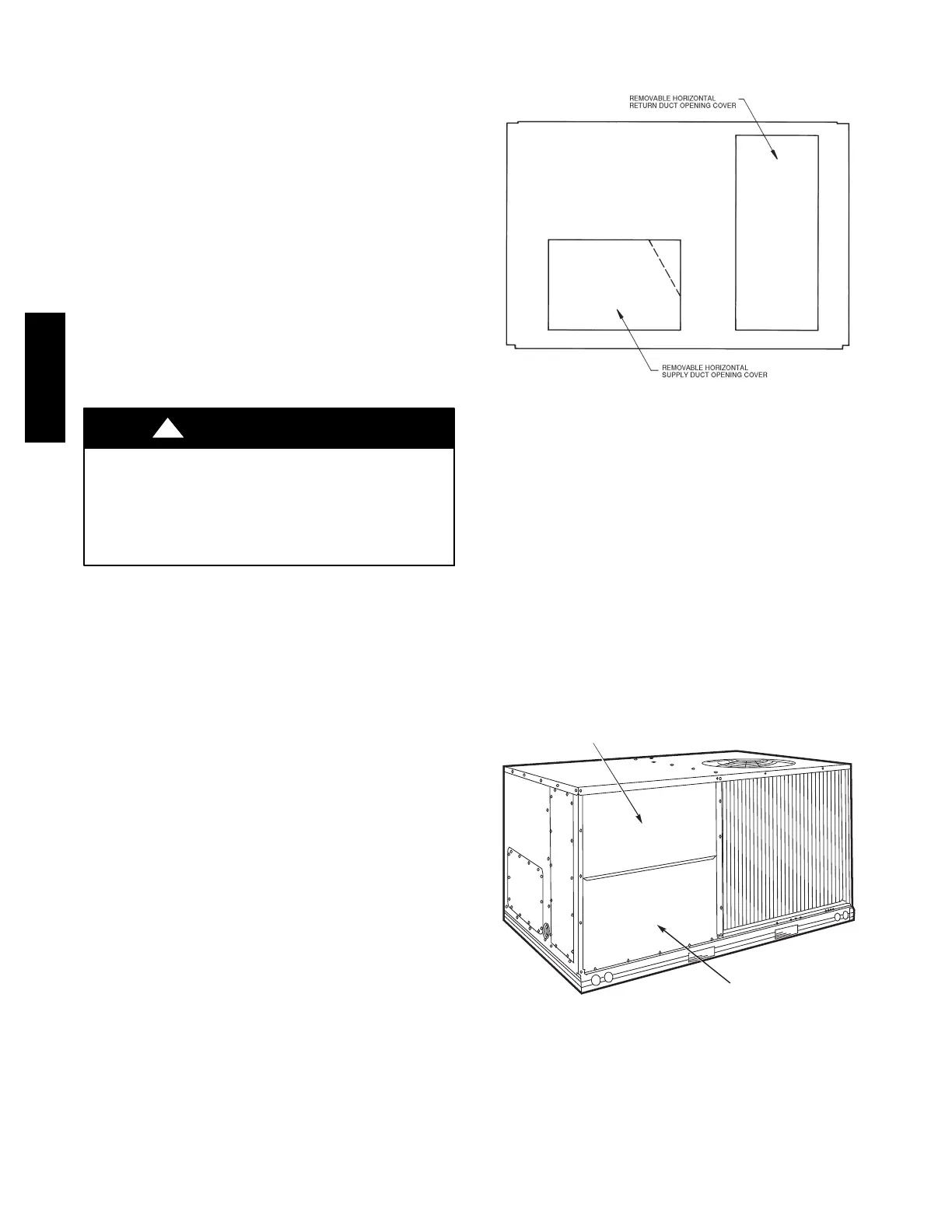

Step 6 — Rig and Place Unit

Keep unit upright and do not drop. Spreader bars are not

requir ed if top crating is left on unit. Roller s may be used to

move unit across a roof. Level by using unit frame as a

reference. See Table 1 and Fig. 7 for additional information.

Lifting hole s are provi ded in base rails as shown in Fig. 7.

Refer to riggi ng instructions on unit.

Rigging materials under unit (cardboard or wood) must be

removed PRIOR to placing t he unit on the roof curb.

When using the standard side drai n connection, ensure the

red plug in the alternate bottom connection is tight. Do

this before setting the unit in place. The red drain pan can

be tightened with a

1

/

2

--in. square socket drive extension.

For further details see Step 9 -- Install External

Condensate Trap and Line on page 14.

Before setting the unit onto the curb, recheck gasketing on

curb.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in

equipment damage.

All panels must be in place when riggi ng. Unit is not

designed for handling by fork truck.

CAUTION

!

PositioningonCurb—

Position unit on roof curb so that the following

clearances are maintained:

1

/

4

in. (6.4 mm) clearance

betwee n the roof c urb and the base rai l i nside the front

and back, 0.0 in. clearance between the roof curb and

the base rail inside on the duct end of the unit. This will

result in the distance between the roof curb and the base

rail i nside on the c ondenser end of t he unit being

approximately

1

/

4

in. (6.4 mm).

Although unit is wea therproof, guard against water from

higher level runoff and overhangs.

After unit is in position, remove rigging skids and

shipping materials.

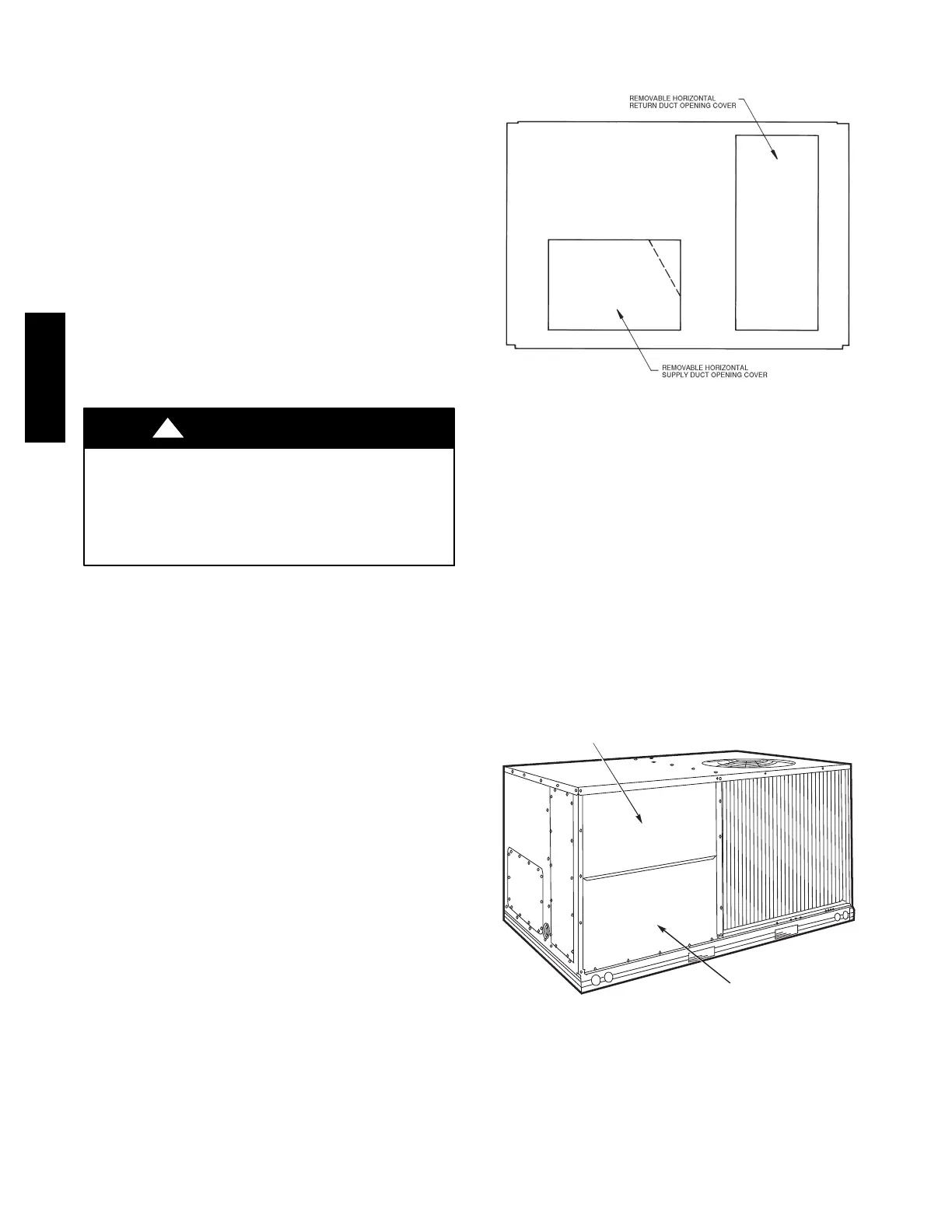

Step 7 — Convert to Horizontal and Connect

Ductwork (when required)

Unit is shipped in the vertical duct configuration. Unit

without factory--installed economizer or return air smoke

detector option may be field--converted to horizontal ducted

configuration. To convert to horizontal configuration,

remove screws from side duct opening covers and remove

covers. Using the same screws, install covers on vertical

duct openings with the insulation--side down. Seals around

duct openings must be tight. See Fig. 8.

Field--supplied flanges should be attac hed to horizontal

duct openings and al l ductwork should be secured to the

flanges. Insulate and weatherproof all external ductwork,

joints, and roof or buil ding openings with count er flashing

and mastic in accordance with applicable codes.

Do not cover or obscure visibility to the unit’s informative

data plate when insulati ng horizontal ductwork.

C06108

Fig. 8 -- Horizontal Conversion Panels

Step 8 — Install Outside Air Hood

Economizer and Two Position Damper Hood

Package Removal and Setup -- Factory Option

1. The hood is shipped in knock--down form and must be

field assembled. The indoor coil access panel is used as

the hood top while the hood sides, divider and filter are

packaged together, attached to a metal support tray us-

ing plastic stretch wrap, and shipped in the return air

compartment behind the indoor coil access panel. The

hood assembly’ s metal tray is attached to the basepan

and also attached to the damper usin g two plastic tie--

wraps.

2. To gain access to the hood, remove the filter access

panel. (See Fig. 9.)

FILTER ACCESS PANEL

INDOOR COIL ACCESS PANEL

C10146

Fig. 9 -- Typical Access Panel Locations

3. Locate the (2) screws holding the metal tray to the

basepan and rem ove. Locate and cut the (2) plastic

tie--wraps securing the assembly to the damper. (See

Fig. 10.) Be careful to not damage any wiring or cut

tie--wraps securing any wiring.

50TC

Loading...

Loading...