ground clamp or any grounded piece of

metal. IMPORTANT! The welding wire is car-

rying welding current whenever the welder is

turned on.

11. Pull the trigger on the welding gun to feed

the wire through the gun assembly.

12. When at least an inch of wire sticks out

past the end of the gun, release the trigger.

13. Install the supplied 0.030 inch (0.8mm)

size contact tip.

Note: Due to inherent variances in flux-

cored welding wire, it may be necessary

to use a welding tip one size larger than

your flux-core wire if jams occur.

14. Slide the contact tip over the wire

(protruding from the end of the gun).

Screw the contact tip into the end of the

gun and hand tighten securely.

15. Install the nozzle on the gun assembly.

16. Cut off the excess wire that extends past

the end of the nozzle.

ARC RAYS CAN INJURE EYES!

To reduce the risk of arc flash, make certain

that the wire coming out of the end of the

gun does not come in contact with the

ground clamp or any grounded material dur-

ing the drive tension setting process.

17. Set the wire drive tension.

a. Pull the trigger on the gun.

b. Turn the drive tension adjustment

knob clockwise, increasing the drive

tension until the wire seems to feed

smoothly without slipping.

Note: If TOO MUCH tension is applied, the

wire will slip on the drive roller or will not be

able to feed at all. If TOO LITTLE tension is

applied, the spool of wire will want to

unspool itself.

When the drive tension is set correctly, there

should be no slippage between the wire and

the drive roller. But if an obstruction occurs

along the wire feed path, the wire should

then slip on the drive roller.

Your new MIG (Metal Inert Gas) Wire Feed

welder is designed for maintenance and

sheet metal fabrication. The welder consists

of a single-phase power transformer, and a

unique built-in control/feeder. This welder is

capable of welding with 0.030 inch

self-shielding flux-core wire.

Now you can weld 18 gauge sheet metal up

to 3/16 inch with a single pass. You can weld

1/4 inch steel with beveling and multiple pass

techniques. Table 2 lists your wire feed

welder specifications.

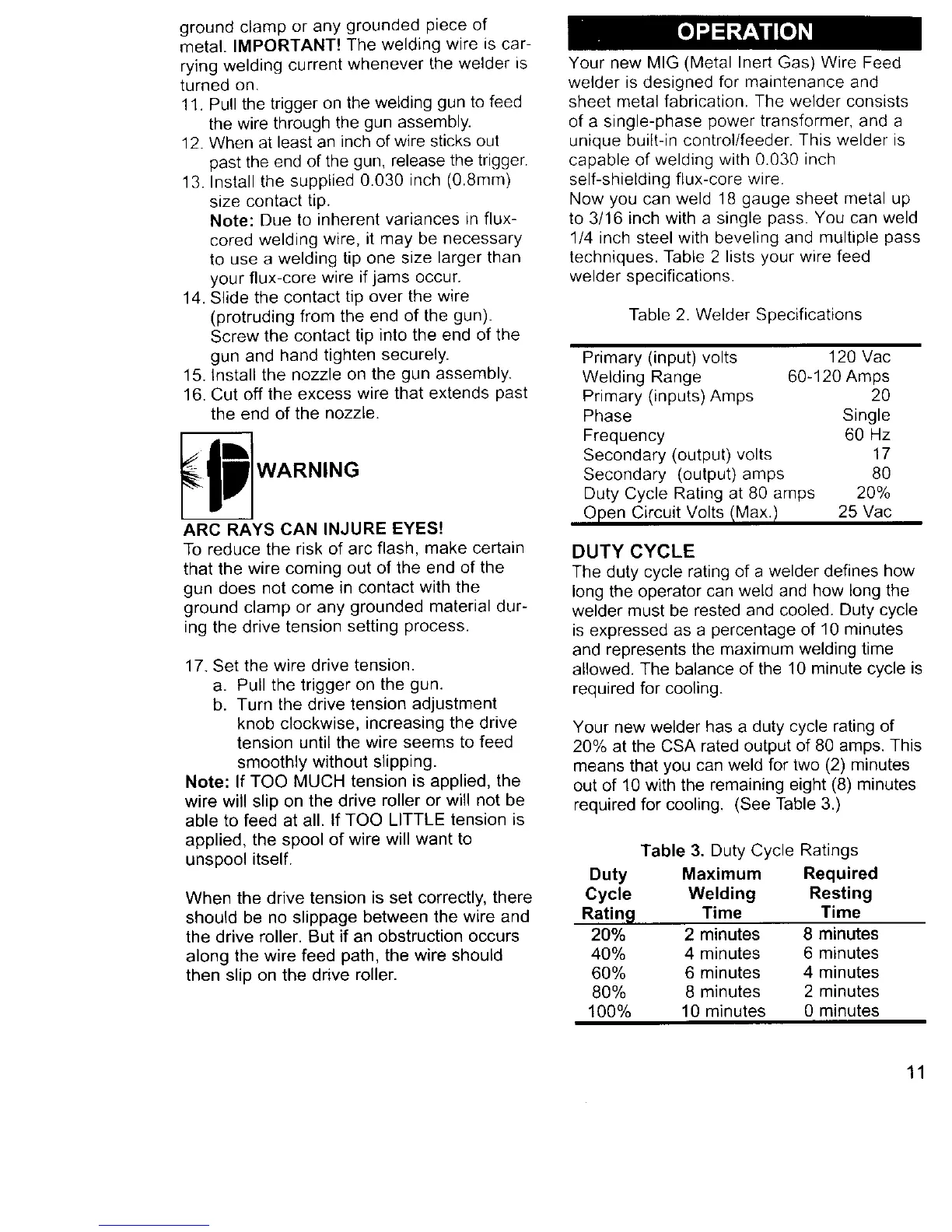

Table 2. Welder Specifications

Primary (input) volts 120 Vac

Welding Range 60-120 Amps

Primary (inputs) Amps 20

Phase Single

Frequency 60 Hz

Secondary (output) volts 17

Secondary (output) amps 80

Duty Cycle Rating at 80 amps 20%

Open Circuit Volts/Max.! 25 Vac

DUTY CYCLE

The duty cycle rating of a welder defines how

long the operator can weld and how long the

welder must be rested and cooled. Duty cycle

is expressed as a percentage of 10 minutes

and represents the maximum welding time

allowed. The balance of the 10 minute cycle is

required for cooling.

Your new welder has a duty cycle rating of

20% at the CSA rated output of 80 amps. This

means that you can weld for two (2) minutes

out of 10 with the remaining eight (8) minutes

required for cooling. (See Table 3.)

Table 3. Duty Cycle Ratings

Duty Maximum Required

Cycle Welding Resting

Rating Time Time

20% 2 minutes 8 minutes

40% 4 minutes 6 minutes

60% 6 minutes 4 minutes

80% 8 minutes 2 minutes

100% 10 minutes 0 minutes

11

Loading...

Loading...