fromthe restofthe gun.Thispermitsthe

operatorto actuallyrestthe nozzleonthe

workpieceanddragitalongwhilewelding.

Thiscanbeveryhelpfultobeginningwelders

to steadythe gun,allowingthe welderto con-

centrateonweldingtechnique.Ifthe nozzleis

heldoffthe workpiece,thedistancebetween

the nozzleandtheworkpieceshouldbekept

constantandshouldnotexceed1/4inchor

thearcmaybeginsputtering,signalinga loss

inweldingperformance

LAYING A BEAD

EXPOSURE TO A WELDING ARC IS

EXTREMELY HARMFUL TO THE EYES

AND SKIN! Prolonged exposure to the weld-

ing arc can cause blindness and burns.

Never strike an arc or begin welding until you

are adequately protected. Wear flameproof

welding gloves, a heavy long sleeved shirt,

cuffless trousers, high topped shoes and a

welding helmet.

_ WARNING

ELECTRIC SHOCK CAN KILL! To prevent

ELECTRIC SHOCK, do not perform any

welding while standing, kneeling, or lying

directly on the grounded work.

WELDING TECHNIQUES

TRAVELING THE GUN

Gun travel refers to the movement of the gun

along the weld joint and is broken into two ele-

ments: Direction and Speed. A solid weld bead

requires that the welding gun be moved

steadily and at the right speed along the weld

joint. Moving the gun too fast, too slow, or

erratically will prevent proper fusion or create a

lumpy, uneven bead.

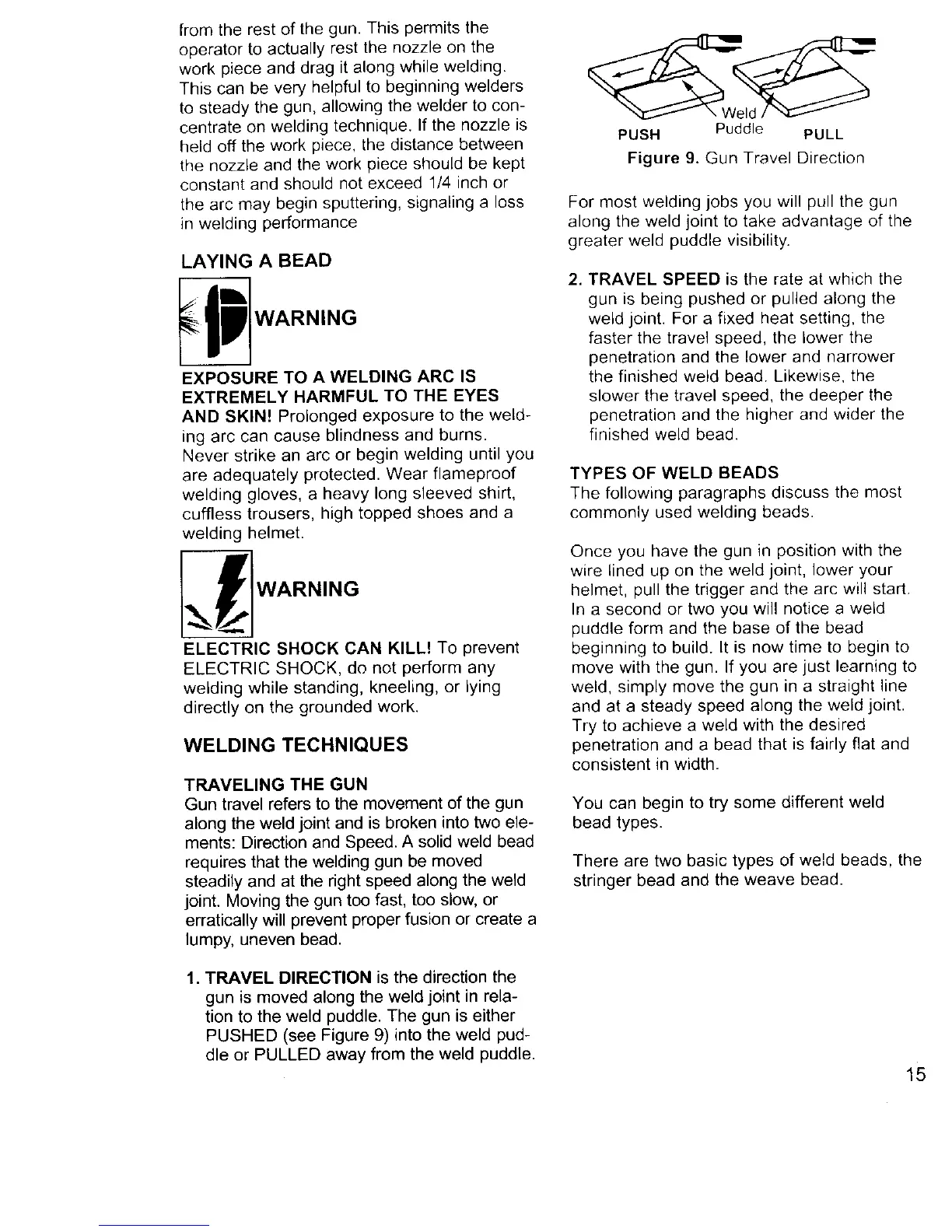

1. TRAVEL DIRECTION is the direction the

gun is moved along the weld joint in rela-

tion to the weld puddle. The gun is either

PUSHED (see Figure 9) into the weld pud-

dle or PULLED away from the weld puddle.

PUSH Puddle PULL

Figure 9. Gun Travel Direction

For most welding jobs you will pull the gun

along the weld joint to take advantage of the

greater weld puddle visibility.

, TRAVEL SPEED is the rate at which the

gun is being pushed or pulled along the

weld joint. For a fixed heat setting, the

faster the travel speed, the lower the

penetration and the lower and narrower

the finished weld bead. Likewise, the

slower the travel speed, the deeper the

penetration and the higher and wider the

finished weld bead.

TYPES OF WELD BEADS

The following paragraphs discuss the most

commonly used welding beads.

Once you have the gun in position with the

wire lined up on the weld joint, lower your

helmet, pull the trigger and the arc will start.

In a second or two you will notice a weld

puddle form and the base of the bead

beginning to build. It is now time to begin to

move with the gun. If you are just learning to

weld, simply move the gun in a straight line

and at a steady speed along the weld joint.

Try to achieve a weld with the desired

penetration and a bead that is fairly flat and

consistent in width.

You can begin to try some different weld

bead types.

There are two basic types of weld beads, the

stringer bead and the weave bead.

15

Loading...

Loading...