LEARNING TO WELD

MIG (Metal Inert Gas) welding is the process

of uniting metallic parts by heating and

allowing the metals to flow together through

the use of an electrical arc. The electrical arc

is created between a continuous consumable

wire electrode (the welding wire) and the

work piece. An inert shielding gas is used to

protect the weld puddle from contamination

and enhance the welding capabilities of the

electrical arc.

Whether you have welded before or not, it is

important that you become familiar with your

new welder, its controls, and the results

achieved at different settings. We strongly

recommend that you practice with your new

welder on scrap metal trying different heat

settings, base metal thicknesses, and weld-

ing positions for each type and size of wire

you will be using. By doing this you will gain

a feel for how changes in these welding

variables affect the weld.

Of course, if you have not welded before,

you will need to develop welding skills and

techniques as well.

The self-taught welder learns through a

process of trial and error. The best way to

teach yourself how to weld is with short

periods of practice at regular intervals. All

practice welds should be done on scrap

metal that can be discarded. Do not attempt

to make any repairs on valuable equipment

until you have satisfied yourself that your

practice welds are of good appearance and

free of slag or gas inclusions. What you fail

to learn through practice will be learned

through mistakes and re-welds later on.

HOLDING THE GUN

The best way to hold the welding gun is the

way that feels most comfortable to you.

While practicing to use your new welder,

experiment holding the gun in different

positions until you find the one that seems to

work best for you.

Position the Gun to the Work Piece

There are two angles of the gun nozzle in

relation to the work piece that must be con-

sidered when welding.

14

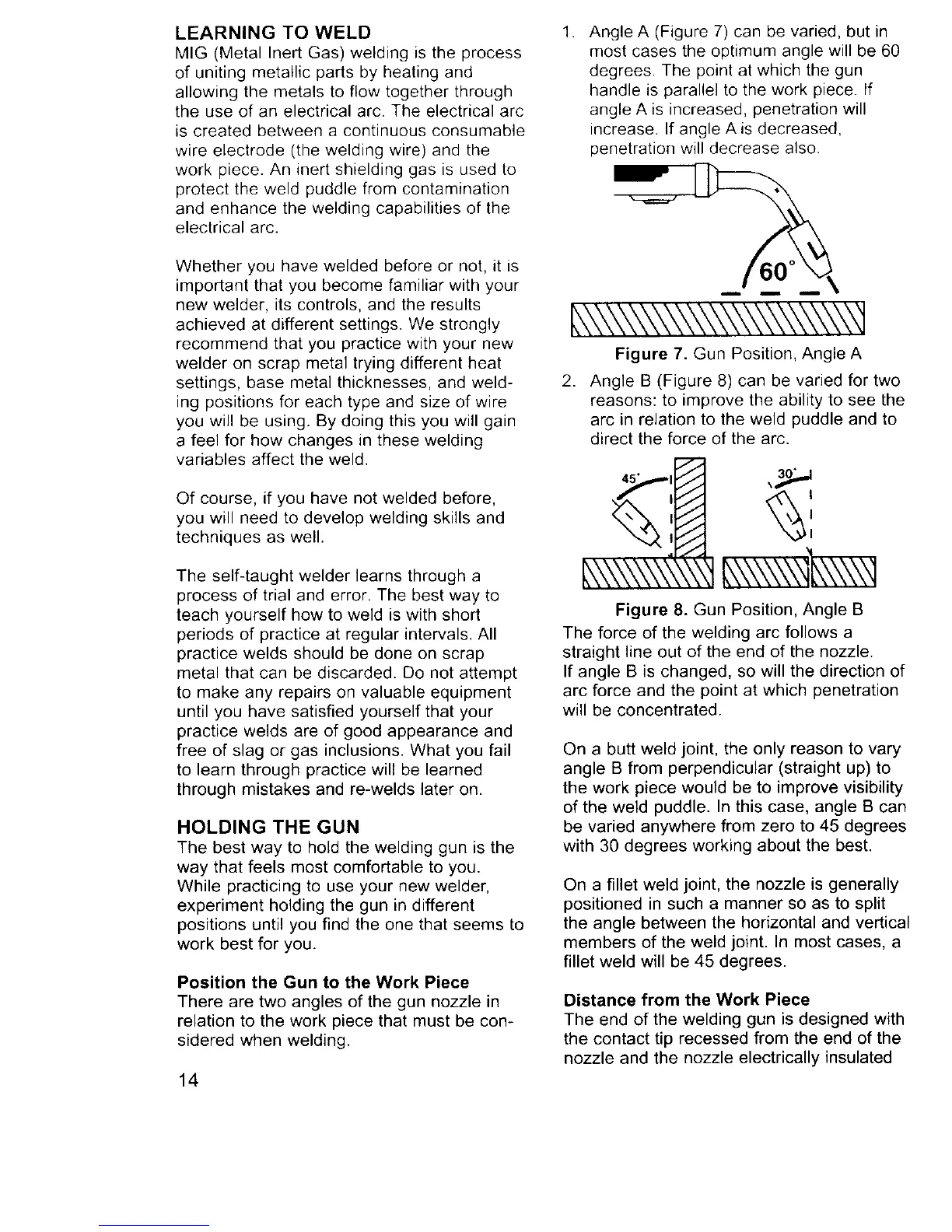

1. Angle A (Figure 7) can be varied, but in

most cases the optimum angle will be 60

degrees. The point at which the gun

handle is parallel to the work piece. If

angle A is increased, penetration will

increase. If angle A is decreased,

penetration will decrease also.

L\\\\\\\\\\\\\\\\\\\\\\\q

Figure 7. Gun Position, Angle A

.

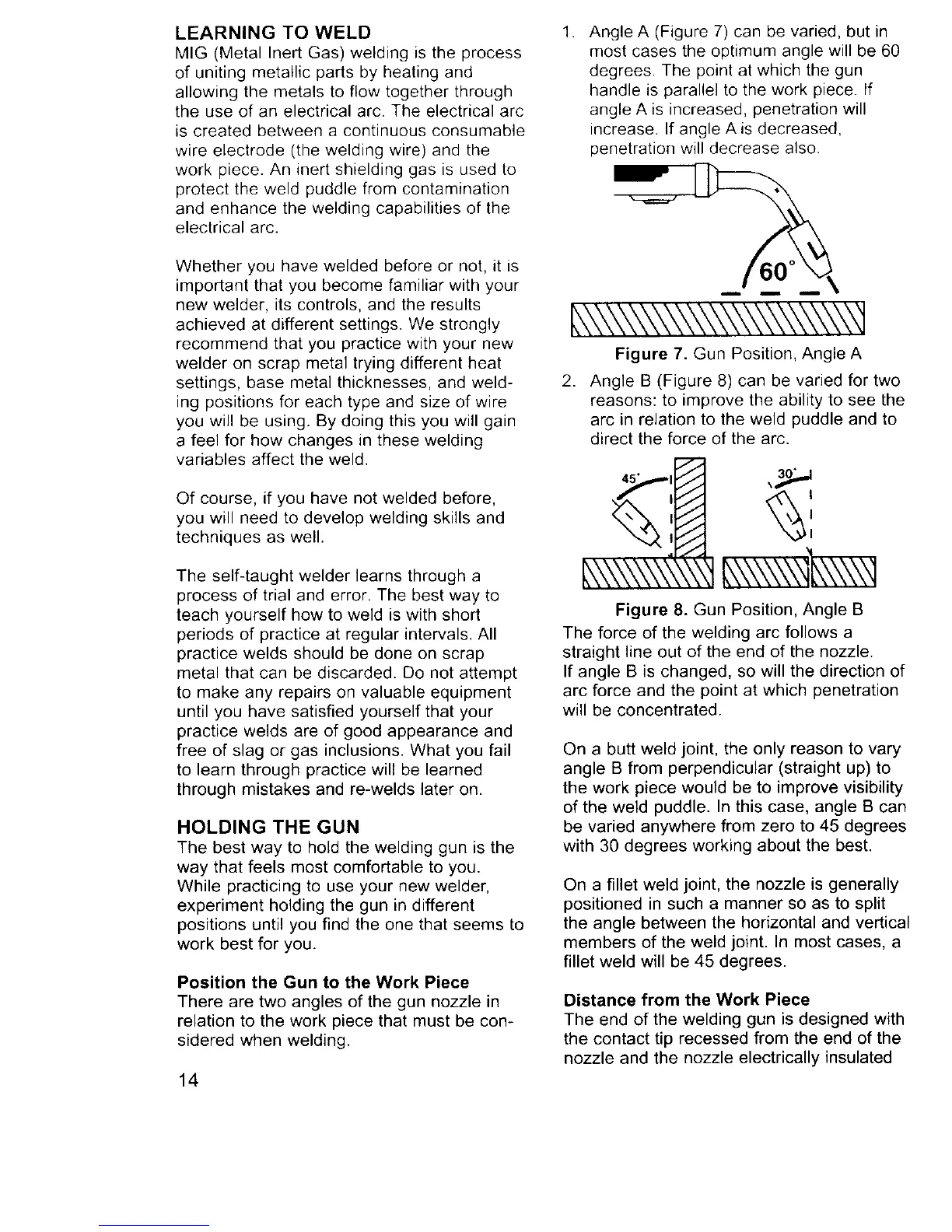

Angle B (Figure 8) can be varied for two

reasons: to improve the ability to see the

arc in relation to the weld puddle and to

direct the force of the arc.

45 ° I

#,\\\\\\\\\\\'t

Figure 8. Gun Position, Angle B

The force of the welding arc follows a

straight line out of the end of the nozzle.

If angle B is changed, so will the direction of

arc force and the point at which penetration

will be concentrated.

Qn a butt weld joint, the only reason to vary

angle B from perpendicular (straight up) to

the work piece would be to improve visibility

of the weld puddle. In this case, angle B can

be varied anywhere from zero to 45 degrees

with 30 degrees working about the best.

On a fillet weld joint, the nozzle is generally

positioned in such a manner so as to split

the angle between the horizontal and vertical

members of the weld joint. In most cases, a

fillet weld will be 45 degrees.

Distance from the Work Piece

The end of the welding gun is designed with

the contact tip recessed from the end of the

nozzle and the nozzle electrically insulated

Loading...

Loading...