30

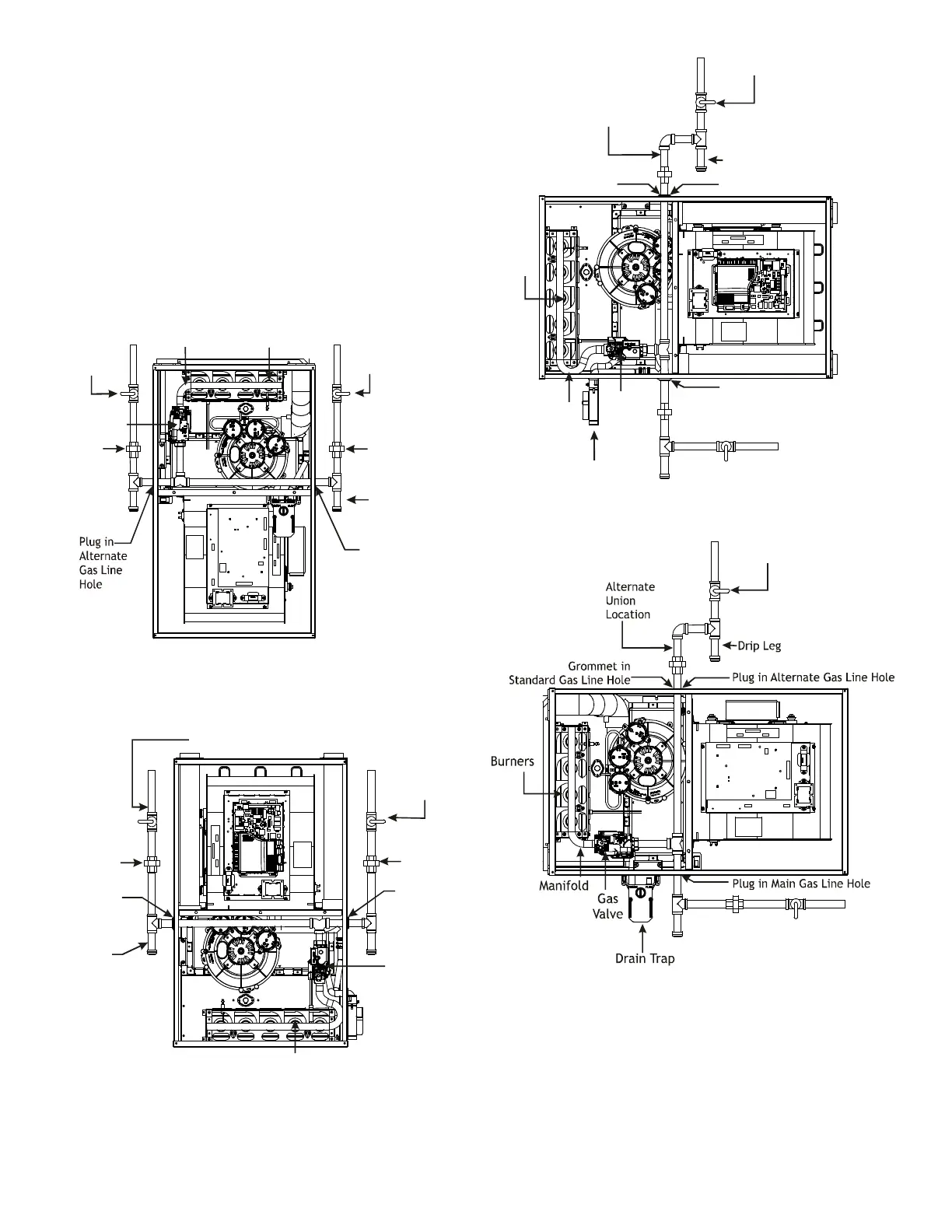

The gas piping may enter the left or right side of the

furnace cabinet. The installer must supply rigid pipe long

enough to reach the outside of the cabinet to seal the

grommet cabinet penetration. A semi-rigid connector to the

gas piping can be used outside the cabinet per local codes.

1/2” NPT pipe and ttings are required. For models with

an “L” shaped manifold, a 4 1/2” long nipple is required.

For models with a hook shaped manifold, a 2” long nipple

is required.

A semi-rigid connector to the gas piping can be used

outside the cabinet per local codes. From the elbow, the

length of pipe and the ttings required will vary by the side

chosen, location of union and cabinet width. The union

may be placed inside or outside of the cabinet.

Alternate

Gas Line

Location

Gas Valve

Burners

Manual Shut Off Valve

(upstream from

ground joint

pipe union)

Drip Leg

Grommet

in Standard

Gas Line

Hole

*Ground

Joint

Pipe

Union

*Ground

Joint

Pipe

Union

*NOTE: Union may be inside furnace cabinet where allowed by local codes.

Manifold

Alternate

Gas Line

Location

Plug in

Alternate

Gas Line

Hole

Gas Valve

Burners

Manual Shut Off Valve

(upstream from ground joint pipe union)

Drip Leg

Grommet

in Standard

Gas Line

Hole

*Ground

Joint

Pipe Union

*Ground

Joint

Pipe Union

*NOTE: Union may be inside furnace cabinet where allowed by local codes.

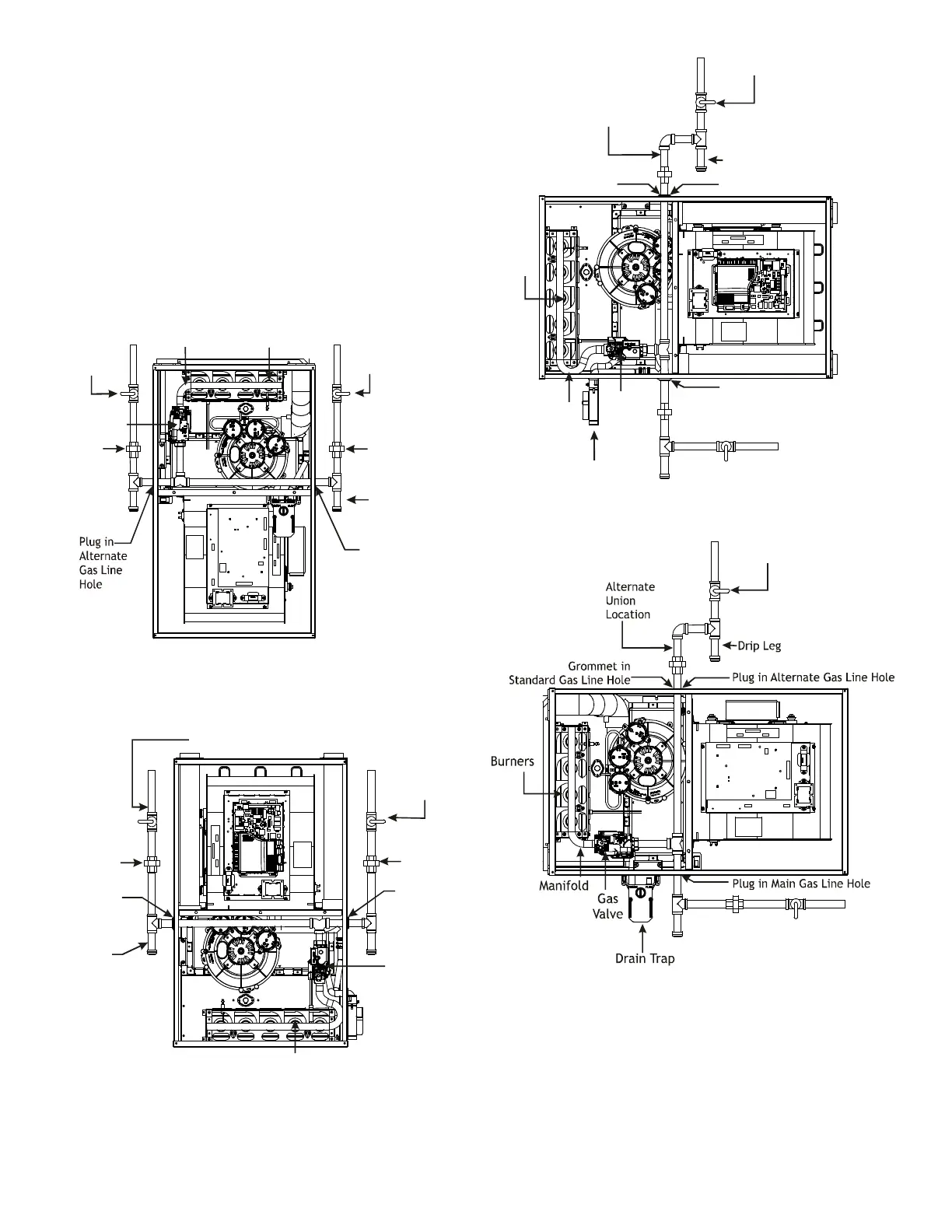

Drip Leg

Plug in Main Gas Line Hole

Alternate

Union

Location

Manual Shut Off Valve

(upstream from

ground joint pipe union)

Gas

Valve

Burners

Drain Trap

Manifold

Plug in Alternate Gas Line Hole

Grommet in

Standard Gas Line Hole

Manual Shut Off Valve

(upstream from

ground joint

pipe union)

Before placing unit in operation, leak test the unit and gas

connections.

Check for leaks using an approved chloride-free soap and

water solution, an electronic combustible gas detector, or

other approved testing methods.

Loading...

Loading...