39

A number of safety circuits are employed to ensure safe

and proper furnace operation. These circuits serve to

control any potential safety hazards and serve as inputs

in the monitoring and diagnosis of abnormal function.

These circuits are continuously monitored during furnace

operation by the integrated control module.

The integrated control module is an electronic device

which, if a potential safety concern is detected, will

take the necessary precautions and provide diagnostic

information through an LED.

The primary limit control is located on the partition panel

and monitors heat exchanger compartment temperatures.

It is a normally-closed (electrically), automatic reset,

temperature-activated sensor. The limit guards against

overheating as a result of insucient conditioned air

passing over the heat exchanger.

The auxiliary limit controls are located on or near the

circulator blower and monitors blower compartment

temperatures. They are a normally-closed (electrically),

manual-reset sensors. These limits guard against

overheating as a result of insucient conditioned air

passing over the heat exchanger.

The rollout limit controls are mounted on the burner/

manifold assembly and monitor the burner ame. They

are normally-closed (electrically), manual-reset sensors.

These limits guard against burner ames not being

properly drawn into the heat exchanger.

The pressure switches are normally-open (closed during

operation) negative air pressure-activated switches. They

monitor the airow (combustion air and ue products)

through the heat exchanger via pressure taps located on

the induced draft blower and the coil front cover. These

switches guard against insucient airow (combustion

air and ue products) through the heat exchanger and/or

blocked condensate drain conditions.

Temperature rise must be within the range specied on the

unit rating plate. An incorrect temperature rise may result

in condensing in or overheating of the heat exchanger.

An airow and temperature rise table is provided in the

Specication Sheet applicable to your model. Determine

and adjust temperature rise as follows:

1. Operate furnace with burners ring for approximately

ten minutes. Ensure all registers are open and all

duct dampers are in their nal (fully or partially open)

position.

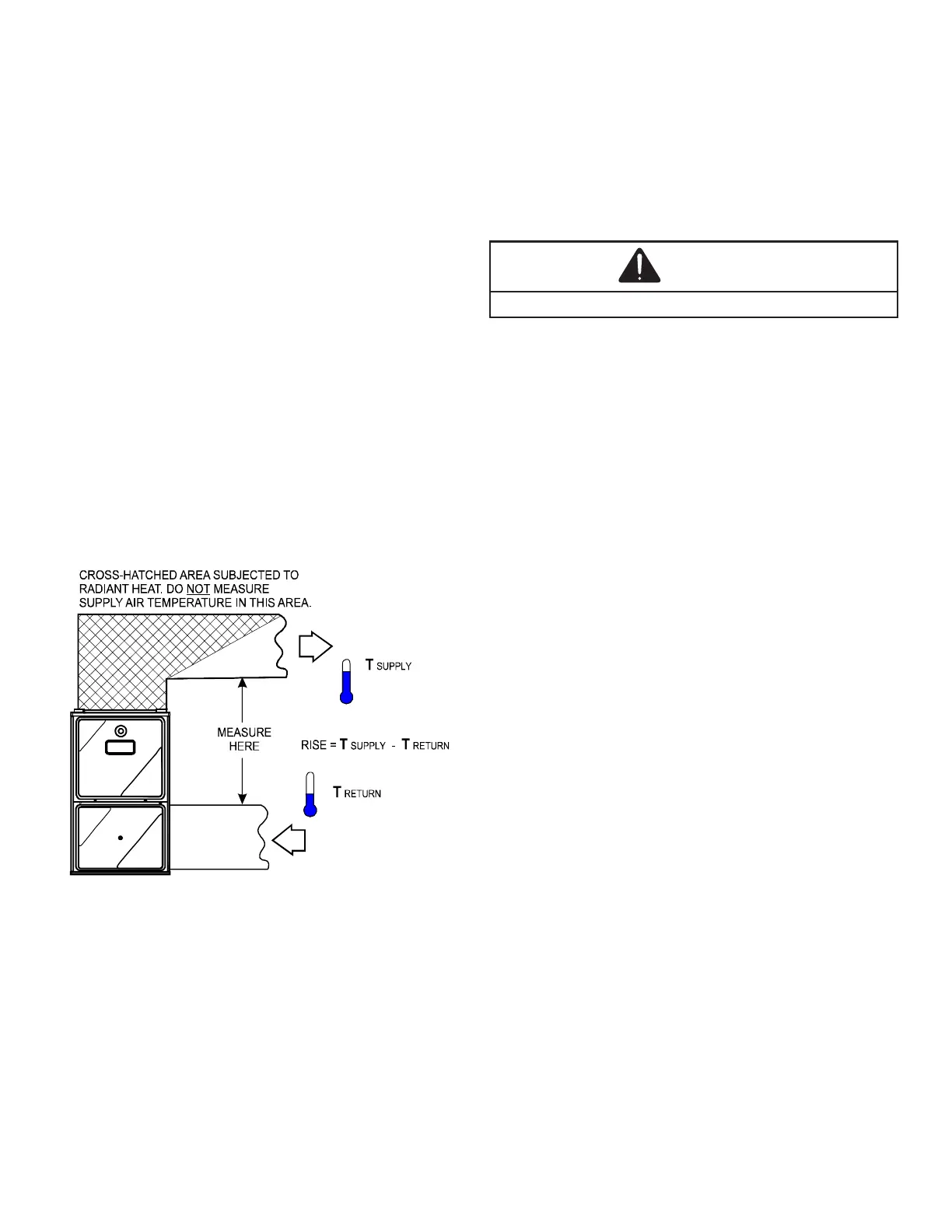

2. Place thermometers in the return and supply ducts

as close to the furnace as possible. Thermometers

must not be inuenced by radiant heat by being able

to “see” the heat exchanger.

3. Subtract the return air temperature from the supply

air temperature to determine the air temperature

rise. Allow adequate time for thermometer readings

to stabilize.

4. Adjust temperature rise by adjusting the circulator

blower speed. Increase blower speed to reduce

temperature rise. Decrease blower speed to

increase temperature rise. Refer to Startup

Procedure and Adjustment - Circulator Blower

Speeds for speed changing details.

The burner ames should be inspected with the burner

compartment door installed. Flames should be stable,

quiet, soft, and blue (dust may cause orange tips but

they must not be yellow). Flames should extend directly

outward from the burners without curling, oating, or lifting

o. Flames must not impinge on the sides of the heat

exchanger ring tubes.